Precision and Power: How a Metal Cutter Machine Can Boost Your Small Business

Finding efficient ways to cut through hard materials like metal, ceramics, and stone can be challenging for a small business owner. That’s where waterjet metal cutter machines come in. In this article, we’ll explore the benefits of investing in one for your business and factors to consider before purchasing. Let’s dive into it!

Introduction to Waterjet Metal Cutter Machines

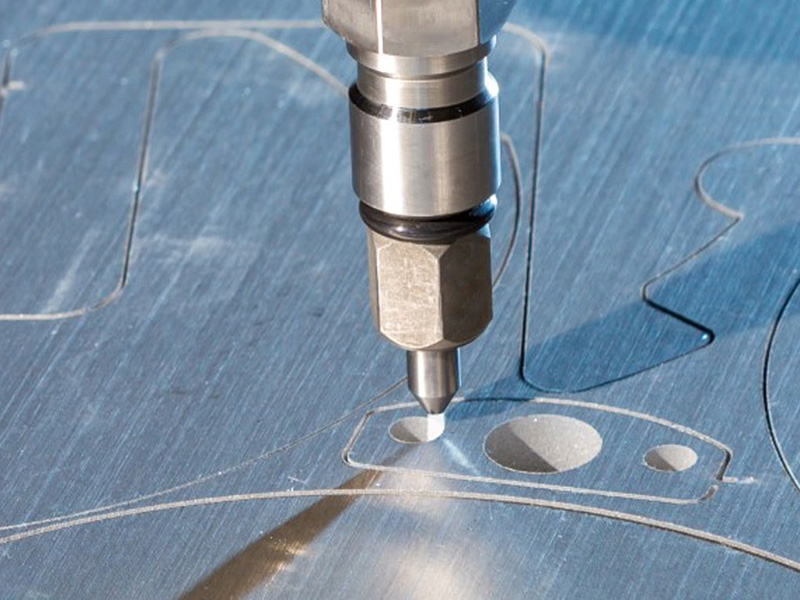

Waterjet metal cutter machines are powerful tools for cutting through stone, metal, and ceramics. These machines use high-pressure water streams to cut through the material accurately. They can be used in various industries, from manufacturing to construction.

One of the critical advantages of waterjet metal cutter machines is their ability to cut through hard materials without causing heat damage or distortion. They combine water and abrasive particles to create the cutting stream. Additionally, some models may have features like pneumatic drilling and laser height detection that further enhance precision and efficiency during operation.

What is a Waterjet Metal Cutter Machine?

Waterjet cutting technology uses a high-pressure stream of water mixed with abrasive particles to cut through hard materials such as metal, stone, and ceramics. It is a versatile method that can be used on various thicknesses and shapes of materials. The assistance of pneumatic drilling or laser height detection adds precision to the process making it an efficient way to produce complex designs.

Waterjet metal cutting machines can cut through various materials, including steel, aluminum, brass, copper, glass, and wood. This flexibility allows small business owners to take on different projects without changing their equipment setup. Compared with other methods like laser or plasma cutting, waterjet cuts do not create heat-affected zones, making them ideal for sensitive materials that could warp from thermal damage during the process.

How Does a Waterjet Metal Cutter Machine Work?

A waterjet metal cutting machine cuts through hard materials like metal, ceramics, and stone using a high-pressure stream of water. The cutting process involves several components, such as an abrasive nozzle, focusing tube, and mixing chamber, that deliver precise cuts. The step-by-step process starts with the high-pressure pump generating pressure to push water into the mixing chamber, mixing it with abrasives before being channeled through the nozzle for cutting. High-pressure pumps are critical since they generate enough pressure to create a focused beam that cuts through the material without causing distortions or burrs.

Without proper care and maintenance of these machines’ components, your business may experience poor performance or even fail due to damaged parts. Investing in a top-of-the-line waterjet metal cutter machine can give your small business an edge over competitors by offering better precision and faster turnaround times on projects requiring intricate designs while utilizing additional features like laser height detection and pneumatic drilling technology for an even more refined cut quality.

Advantages of Waterjet Metal Cutter Machines

Waterjet metal cutter machines offer a range of advantages for small business owners looking to cut through hard materials with precision and accuracy. With advanced software capabilities, these machines can make highly accurate cuts, minimizing material distortion or warping during the cutting process. Additionally, waterjets don’t generate heat-affected zones, making them ideal for cutting sensitive materials like plastic and rubber.

Some of the key benefits of investing in a waterjet metal cutter machine include the following:

- Precision and accuracy in cuts using advanced software capabilities

- No heat-affected zones, minimizing material distortion or warping during cuts

- Minimizing waste by nesting parts together on raw materials to save time and money

Waterjets also have other advantages, such as pneumatic drilling help in piercing into tough metals, and laser height detection technology allows for greater control over the final product quality while reducing manual input requirements.

Benefits for Small Business Owners

Investing in a waterjet metal cutter machine can increase efficiency and productivity for small business owners. Unlike traditional cutting methods, waterjet machines use high-pressure streams of water mixed with abrasive materials to cut through hard materials such as stone, metal, and ceramics quickly and effectively. This means you can finish more work in less time without sacrificing quality or accuracy.

Another benefit of a waterjet metal cutter machine is its versatility in cutting options. This equipment allows you to customize your cuts to fit your specific needs. Whether you need intricate designs or simple straight lines, a waterjet machine can easily handle everything. Plus, because it’s so precise, there’s less material waste, leading to further cost savings in the long run for small business owners looking for ways to maximize their profit margins.

Increased Efficiency and Productivity

When it comes to cutting through hard materials such as metal, stone, or ceramics, speed and precision are essential. Due to its advanced technology, a waterjet metal cutting machine can provide both faster cutting rates and increased productivity. Additionally, with reduced downtime for maintenance compared to other traditional cutting methods, your business can save time and money in the long run.

Another advantage is cutting multiple materials at once without sacrificing accuracy or quality. This increases efficiency by reducing the need for separate machines or tools for different types of material. By investing in a waterjet metal cutter machine, you’ll not only improve your overall productivity but also increase your output capabilities while maintaining high-quality standards.

Ability to Cut Through Hard Materials

A waterjet metal cutter machine is a powerful and efficient way to cut through hard materials such as stone, metal, and ceramics. Its ability to provide precise cuts with minimal material waste makes it an ideal choice for small business owners who need to produce high-quality products quickly.

Here are some of the benefits that a waterjet metal cutter machine can offer your small business:

- Precise Cuts with Minimal Material Waste:

Waterjets use high-pressure streams of water mixed with abrasive particles to cut through rigid materials without leaving jagged edges or burrs behind. This means less time spent on finishing work and more finished products ready for sale.

- No Heat Affected Zones or Distortion of the Material:

Unlike other laser or plasma cutting methods, waterjets don’t generate heat during cutting. This eliminates any risk of warping, distortion, or damage to the cut material.

- Cost Savings on Tooling and Equipment Required for Secondary Processing:

With a waterjet cutter, you won’t have to invest in the expensive tooling required by other traditional cutting methods. You’ll also save money by reducing secondary processing operations since cleanup is minimized due to no smoke or dust generated during the operation.

Investing in a waterjet metal cutter machine can ultimately help increase productivity while saving time and money in production costs.

Cost Savings in the Long Run

Investing in a waterjet metal cutter machine can lead to significant cost savings in the long run. Waterjets have lower energy costs than other cutting methods, so you’ll spend less on electricity bills. Additionally, waterjets produce less material waste than other cutting machines, reducing raw material costs over time.

Furthermore, using a waterjet machine increases automation and reduces labor costs since cutting requires minimal human intervention. These cumulative cost savings make investing in a high-quality waterjet metal cutter machine an attractive option for small business owners looking to optimize their budget while maintaining excellent output quality.

Versatility in Cutting Options

A waterjet metal cutter machine offers your small business a versatile range of cutting options to enhance productivity and efficiency. Here are some advantages of waterjet technology:

- Ability to cut intricate shapes with ease:

The precision of the water jet stream allows for complex cuts, angles, and edges that are difficult or impossible to achieve with other methods.

- Flexibility with thickness and hardness of materials:

Unlike traditional cutting tools, a waterjet machine can handle thick materials up to 8 inches and hard materials such as metals, stone, and ceramics without damaging them.

- Addition of abrasive Waterjet functionality allows for faster, more efficient cutting:

By combining high-pressure water streams with abrasive particles like garnet sand, this feature adds versatility to material choices.

In summary, by investing in a quality waterjet metal cutter machine, you gain incredible capabilities in terms of versatility which could help you produce better products at lower costs.

Conclusion

Investing in a waterjet metal cutter machine can be one of the smartest decisions for your small business. Not only does it provide unparalleled precision and efficiency when cutting through rigid materials, but it also saves time and money in the long run. With its versatility and ease of use, a waterjet cutter can quickly become an indispensable tool for any business that deals with hard materials regularly.

In conclusion, if you are looking for a powerful, efficient way to cut through hard materials such as stone, metal, and ceramics, look no further than investing in a waterjet metal cutter machine for your small business. It will improve productivity while saving time and money by reducing waste material and providing greater accuracy than traditional cutting methods. Don’t hesitate to take advantage of this innovative technology today!