Waterjet Cutting Composite

Discover the Unmatched Benefits of VICHOR Technology

Introduction to Waterjet Cutting Composite

Brief Overview of Waterjet Cutting Composite

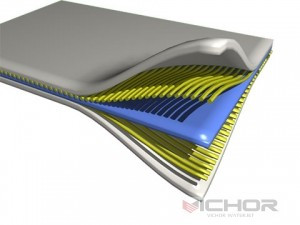

Waterjet cutting composite is an innovative technology that offers unparalleled advantages in the manufacturing sector. It involves the use of high-pressure water, often combined with an abrasive substance, to cut through various materials, including composite materials. Introduced by VICHOR, this cutting-edge technology is swiftly revolutionizing the way we handle composite materials. As a leading company in the industry, VICHOR has successfully integrated waterjet cutting technology to provide precise, efficient, and eco-friendly cutting solutions.

Why Choose Waterjet for Cutting Composite Materials

Choosing waterjet cutting for composites transcends conventional cutting methods in several ways. Given the complex nature of composite materials, many traditional cutting technologies often lead to tool wear and tear or material degradation. Waterjet cutting, on the other hand, provides a non-thermal, force-free cutting process. This eliminates the risk of heat-affected zones or mechanical stresses, ensuring the integrity of the composite material. When it comes to precision, versatility, and environmental sustainability, waterjet cutting technology emerges as the top choice for handling composite materials.

Challenges in Cutting Composite Materials

Nature of Composite Materials

Nature of Composite Materials

Composite materials are heterogeneous by nature, meaning they consist of different components that contribute to their overall strength and functionality. The integration of various materials, such as fibers or resins, leads to a product with enhanced properties compared to its individual constituents. However, this non-homogeneity presents significant challenges when it comes to cutting these materials. Traditional cutting methods often struggle with maintaining precision and reducing damage during the cutting process.

Limitations of Traditional Cutting Methods

Traditional cutting methods, while effective for some applications, show several limitations when it comes to handling composite materials. Mechanical cutting tools, such as saws or routers, can lead to delamination or fraying of the composite material. Thermal cutting methods, like laser or plasma, can cause thermal damage or distortions, compromising the integrity of the composite. These methods also tend to require more time for setup and finishing, resulting in longer production times and higher costs. This is where waterjet cutting, particularly VICHOR’s waterjet cutting composite, sets itself apart. By offering a non-contact, versatile, and precise cutting solution, it effectively addresses these challenges and pushes the boundaries of composite material processing.

The Uniqueness of VICHOR Waterjet in Composite Cutting

The Technology Behind VICHOR Waterjet Cutting Composite

The hallmark of VICHOR Waterjet lies in the advanced technology we incorporate into our waterjet cutting systems. We use a combination of high-pressure water and fine garnet abrasive, propelled at supersonic speeds, to achieve precise and clean cuts through composite materials. Additionally, our technology supports computer-aided control, enabling intricate, custom cuts with little to no effort.

VICHOR’s Edge over Traditional Cutting Methods

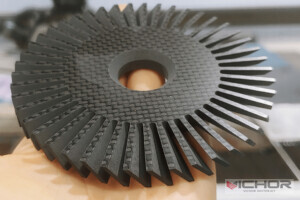

VICHOR stands distinct in the realm of composite cutting, outperforming traditional methods in more ways than one. Unlike conventional techniques, our waterjet technology avoids heat production, thereby eliminating thermal damage risks. It allows for cutting in any direction, meaning complex shapes can be achieved with minimal waste. Plus, it delivers precise cuts on a broad spectrum of materials, from granite to foam, which adds to its versatility.

VICHOR’s Two-year Warranty Advantage

At VICHOR, we believe in the durability and reliability of our waterjet cutting machines. Our confidence is backed by a unique two-year warranty for the entire machine – a feature that makes us stand out in the market. Our commitment to quality and customer satisfaction underscores our dedication to delivering the best waterjet cutting solutions.

Advantages of Waterjet Cutting Composite

Creating Complex Shapes with Precision

Creating Complex Shapes with Precision

VICHOR’s waterjet cutting composite technology introduces a new realm of possibilities for fabricators and designers alike. By harnessing the power of computer-controlled precision and high-pressure waterjets, intricate and complex designs can be crafted from composite materials with unparalleled precision. This level of accuracy allows businesses to expand their product offerings and raise the bar for quality in their industry.

No Heat Affected Zone (HAZ): A Perfect Match for Composites

One of the salient benefits of using VICHOR’s waterjet cutting for composite materials is the absence of a Heat Affected Zone (HAZ). Traditional cutting techniques, such as laser or plasma cutting, generate heat that can degrade or distort the material being cut, adversely affecting its structural integrity. With our waterjet technology, no heat is produced during the cutting process, ensuring the composites maintain their properties and quality.

Omni-Directional Cutting with VICHOR Waterjet: Minimizing Waste

An innovative feature of VICHOR’s waterjet cutting is its omni-directional cutting capability. This means the cutting jet can move in any direction, enabling it to cut complex shapes out of composite materials without causing wastage. As a result, you can expect an efficient cutting process with minimal material waste, promoting sustainability and reducing costs.

Versatility of VICHOR Waterjet: Cutting from Granite to Foam

When it comes to versatility, few can compete with VICHOR’s waterjet cutting. Capable of slicing through an impressive range of materials, our machines are as effective on tough granite as they are on soft foam. This versatility ensures that regardless of the material, whether it’s a composite, metal, or foam, waterjet cutting delivers exceptional results.

No Tool Sharpening with VICHOR Waterjet

Traditional cutting methods often require regular tool sharpening or replacement, adding to the operational costs and downtime. VICHOR’s waterjet cutting composite technology, on the other hand, involves a non-contact cutting process, eliminating the need for tool sharpening. This attribute translates to reduced maintenance costs and more time spent on productive activities.

High or Low Surface Pressure Flexibility with VICHOR Waterjet

VICHOR’s waterjet cutting systems offer flexibility in adjusting the cutting pressure based on the material being processed. The systems can handle high pressure for robust and dense materials, or they can be adjusted to lower pressures for delicate and sensitive materials. This capability ensures optimal cutting conditions are always achieved, maintaining the integrity of the material while ensuring precision cuts.

Cutting Composite Materials with Tolerances at ±0.003″/.076 mm

Precision is paramount in the manufacturing industry, especially when dealing with composite materials. VICHOR’s waterjet cutting technology excels in delivering this precision, cutting materials with tolerances as tight as ±0.003″/.076 mm. This level of accuracy opens new possibilities for manufacturers and fabricators, allowing the production of components with tight tolerances, intricate designs, and high-quality finishes.

Environmental Considerations of Waterjet Cutting Composite

Safety and Environmental Impact of Waterjet Cutting

In an era where businesses are held to high environmental standards, VICHOR’s waterjet cutting composite technology stands as a greener solution. Our waterjet cutting process generates no harmful fumes or dust, significantly reducing air pollution compared to traditional cutting methods. Furthermore, it employs a non-thermal cutting process, removing the risk of burns and fires. This makes VICHOR’s waterjet technology an environmentally friendly and safe option for cutting composite materials.

Responsible Disposal of Used Garnet from Waterjet Cutting

The garnet abrasive used in waterjet cutting can be disposed of responsibly, further cementing waterjet technology as an eco-friendly choice. At VICHOR, we advise our customers on proper methods of garnet disposal, ensuring that we do our part in minimizing environmental impact.

Making the Decision: Is Waterjet Cutting Composite Right for Your Business?

Evaluating Your Business Needs

Deciding whether waterjet cutting is the right choice for your business involves a thorough evaluation of your needs. Do you require precision and versatility in cutting various materials? Are you looking to minimize material waste and operational costs? If so, VICHOR’s waterjet cutting technology could be the optimal solution for you.

The Cost-effectiveness of VICHOR Waterjet Cutting Composite

Waterjet cutting composite technology can be a cost-effective choice for businesses. With its ability to cut complex shapes precisely, minimize waste, and eliminate the need for tool sharpening or replacement, VICHOR’s waterjet technology can significantly reduce operational costs. Furthermore, the ability to cut a wide range of materials with a single machine reduces the need for multiple specialized machines, resulting in further cost savings.

Real Customer Experiences with VICHOR Waterjet

Don’t just take our word for it; consider the experiences of our satisfied customers. We have a strong reputation among our clients, not only for the quality of our waterjet cutting machines but also for our excellent after-sales service. We are proud to provide real customer information for potential clients to discuss our product quality and service. Trust VICHOR Waterjet for your composite cutting needs – our technology, customer service, and reliable machines speak for themselves.

Frequently Asked Questions about Waterjet Cutting Composite

Can VICHOR Waterjet Cut Through Any Composite Material?

Yes, VICHOR Waterjet is designed to cut through a wide array of composite materials with varying densities. Its robust technology and flexible settings enable it to handle materials as tough as carbon fiber composites and as delicate as foam composites.

What Is the Maximum Thickness of Composite Material VICHOR Waterjet Can Cut?

VICHOR Waterjet is capable of cutting composite materials up to 8” (20 cm) thick. However, the cutting thickness can vary depending on the density of the composite material.

How Does VICHOR Waterjet Ensure Precision Cutting without a Heat Affected Zone?

VICHOR Waterjet employs high-pressure water streams to cut through materials, a process that doesn’t generate heat. This way, the composite material retains its structural integrity and properties, thereby delivering precision cuts without a Heat Affected Zone.

How Does Waterjet Cutting Composite Contribute to Environmental Safety?

Waterjet cutting composite is environmentally safe as it generates no toxic fumes or dust during the cutting process. Furthermore, the garnet abrasive used in the cutting process can be responsibly disposed of, minimizing its environmental impact.

Conclusion: The Future of Composite Cutting with VICHOR Waterjet

The Increasing Demand for Composite Materials

As industries continue to discover the benefits of composite materials – their strength, light weight, and versatility – the demand for these materials is set to increase. Consequently, the need for a reliable, precise, and cost-effective cutting solution like VICHOR Waterjet will continue to rise.

Staying Ahead with VICHOR Waterjet in the Composite Cutting Industry

In an evolving industry landscape, staying ahead of the curve is critical. By choosing VICHOR Waterjet, businesses can leverage the power of innovative, high-precision, and versatile cutting technology. With its ability to cut a wide range of materials precisely, VICHOR’s waterjet cutting composite technology is equipped to meet the growing demands of the composite industry. Choose VICHOR – the future of composite cutting is here.