Waterjet Cutting Glass

VICHOR’s Innovative Approach to Perfectly Cut Glass Every Time

Introduction to VICHOR and Waterjet Cutting

VICHOR: Pioneers in Waterjet Cutting

For years, VICHOR has been at the forefront of innovation in the field of waterjet cutting. Our highly skilled team, equipped with state-of-the-art technology, has developed cutting solutions that continue to redefine the industry standards. We are committed to delivering top-notch quality and precision, ensuring that you, our valued customer, have the best tools at your disposal to bring your creative visions to life.

Understanding the Basics of Waterjet Cutting

Waterjet cutting is a versatile and efficient method that utilizes a high-pressure stream of water, often mixed with an abrasive substance, to cut through various materials. Unlike traditional cutting methods, waterjet cutting doesn’t produce heat, thereby eliminating the risk of warping or distorting the material. This process is not only beneficial for cutting hard materials like metal and stone but is also perfect for delicate materials like glass, which require a gentler touch.

Why Choose Waterjet Cutting for Glass

When it comes to glass cutting, precision, smoothness, and safety are of utmost importance. Waterjet cutting glass is a cost-effective method that allows for intricate contours and shapes, which other cutting machines cannot achieve at a reasonable cost. With the ability to cut almost any glass application, from artistic tabletop inlays to detailed stained glass designs, VICHOR Waterjet offers unrivaled versatility and precision.

The Science Behind Waterjet Cutting Glass

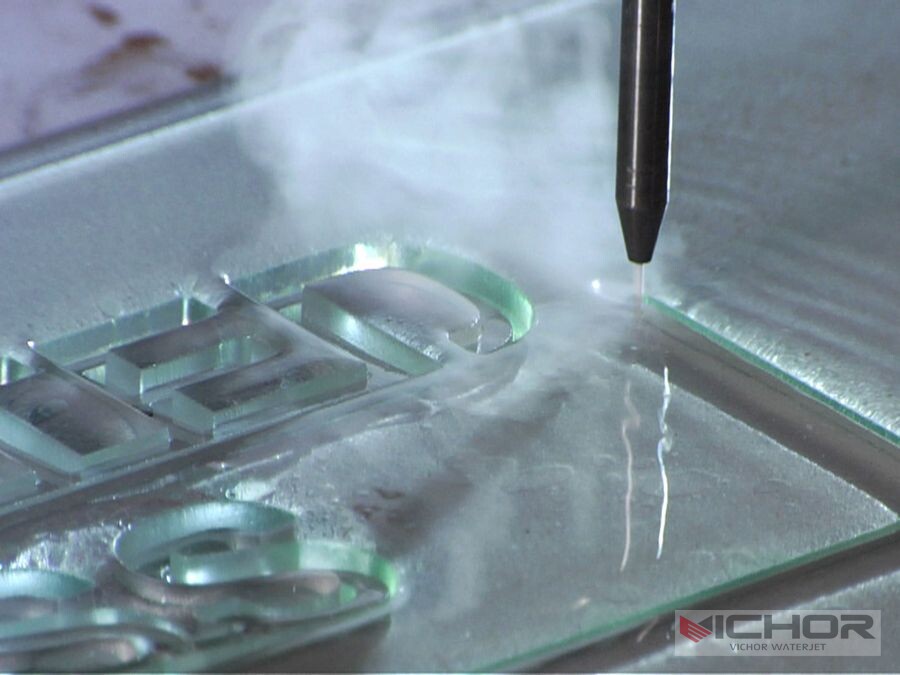

Unveiling the Abrasive Waterjet Cutting Technology

Unveiling the Abrasive Waterjet Cutting Technology

Abrasive waterjet cutting technology is a game-changer in the glass cutting industry. The process involves the use of waterjet mixed with abrasive materials, propelled at high velocity, to make precise cuts on the glass. This method allows for the creation of detailed designs and shapes that would be impossible with conventional cutting tools.

The Crucial Role of Reduced Pressure in Glass Cutting

One of the critical aspects of successful waterjet glass cutting is the careful regulation of pressure. Glass has a propensity to crack, which necessitates that the initial holes be produced at a reduced pressure, ranging between 7,200 PSI/500 bar and 11,600 PSI/800 bar. This reduced pressure ensures that the glass remains intact during the initial stages of the cutting process.

Proportional Pressure Control: The Key to Avoiding Material Destruction

To prevent the destruction of the glass during the cutting process, it is essential to gradually increase and reduce the cutting pressure. This is achieved through the proportional pressure control of the intensifier pump, an innovation that ensures the glass is not subjected to sudden changes in pressure, which could lead to breakage.

Alternatives to Quartz Sand: The Use of Olivine

While quartz sand is commonly used as an abrasive in waterjet cutting, olivine provides an excellent alternative. Olivine is softer than quartz, which reduces the potential for chipping, cracking, and other surface blemishes. Moreover, it leaves a cut edge that is polished to a smooth finish, minimizing the need for further finishing work. This is particularly beneficial when working with glass, where a smooth, polished edge is often desired.

Types of Glass Suitable for Waterjet Cutting

Flat Glass: The Standard in Glass Cutting

Flat Glass: The Standard in Glass Cutting

Flat glass is the most common type used in waterjet cutting. Whether you’re working on a flat glass piece with numerous contours or a simple straight cut, VICHOR’s waterjet cutting machines can handle it with ease and precision.

Laminated Glass: Complex but Achievable with VICHOR

Cutting laminated glass can be tricky due to its layered nature, but with our waterjet cutting technology, it’s entirely achievable. VICHOR waterjets can cut through these layers cleanly without delamination, maintaining the integrity of the glass.

Bullet-Proof Glass: Cutting with Precision and Safety

Bullet-proof glass, known for its toughness and thickness, is another material that can be efficiently cut using VICHOR waterjet technology. Our machines can accurately cut through this dense material while ensuring safety and precision.

Lenses and Optical Laser Parts: The Importance of Precision

In industries like electronics and medical, precision is paramount, especially when cutting glass components such as lenses and optical laser parts. VICHOR waterjets can deliver highly precise cuts, making them the ideal choice for these critical applications.

Mirrors: Delicate but Possible with VICHOR’s Technology

Despite their fragility, mirrors can also be cut using VICHOR’s waterjet technology. The low-pressure start and controlled cutting process ensure the mirror’s surface remains intact and crack-free.

Limitations: Why Tempered or Hot Glass is Unsuitable for Waterjet Cutting

While waterjet cutting is incredibly versatile, it’s important to note that it’s not suitable for all types of glass. Tempered or hot glass, for instance, can’t be cut using a waterjet as the process could cause the glass to shatter.

Advantages of Glass Waterjet Cutting with VICHOR

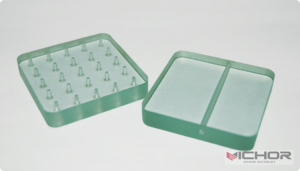

Unparalleled Geometry: Cutting Shapes Unachievable by Conventional Machining

Unparalleled Geometry: Cutting Shapes Unachievable by Conventional Machining

One of the standout advantages of VICHOR waterjet cutting is its ability to cut glass into shapes and designs that traditional machining can’t achieve. From intricate artistic designs to complex industrial components, our waterjets make the impossible possible.

Safety of Delicate Glass: No Cracks During Processing

VICHOR’s waterjet cutting technology ensures that even the most delicate glass doesn’t crack during processing. The careful regulation of cutting pressure ensures that the glass remains intact, resulting in a flawless end product.

Versatility in Thickness: Precision from Thin to Thick Glass

Whether you’re working with thin glass or a thick slab, VICHOR waterjets can handle it all without the need for changing tooling. They can cut glass panels up to 9″ (23 cm) in thickness, providing unprecedented versatility.

No Heat Affected Zone (HAZ): Keeping the Glass Intact

Unlike other cutting methods that generate heat, waterjet cutting doesn’t create a heat-affected zone. This eliminates the risk of glass warping or distorting, resulting in a smoother, more precise cut.

Eliminating Material Waste: The Economic Efficiency of Narrow Cutting Gaps

Waterjet cutting also offers economic efficiency by reducing material waste. Thanks to the narrow cutting gap, you can make the most out of every glass sheet, saving both material and cost.

Intricate Design Capabilities: VICHOR’s Special Edge

The precision and control offered by VICHOR waterjets allow for the creation of intricate designs in any shape and size. This opens up endless possibilities for artistic expression and industrial design, giving VICHOR a unique edge in the glass cutting industry.

Everyday Applications of Waterjet Cutting Glass

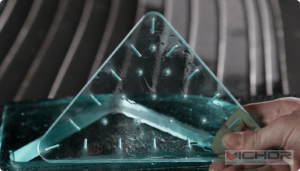

Artistic Applications: From Tabletop Inlays to Stained Glass

Waterjet cutting has a wide range of artistic applications. Whether you’re creating tabletop inlays, intricate stained glass designs, delicate glass ornaments, or detailed church mosaics, VICHOR waterjets offer the precision and flexibility you need to bring your artistic vision to life.

Practical Uses: From Shower Screens to Kitchen Splashbacks

In addition to artistic applications, waterjet cutting is also used for a variety of practical purposes. Frameless shower screens, kitchen and bathroom splashbacks, window panels, and mirrors can all be cut to size and shape with precision and efficiency using our waterjet technology.

Industrial Applications: From Laminated Glass to Optical Laser Parts

VICHOR’s waterjet cutting technology is widely used in industries that require precise and high-quality glass components, such as the electronic and medical industries. Whether it’s laminated glass, optical laser parts, lenses, or other specialized glass components, our machines deliver exceptional results every time.

Unique Projects: Replacement Glass for Antique Autos and More

Our waterjet cutting machines can also be used for unique projects like cutting replacement windows for antique cars, creating custom light fixtures, and crafting unique glass ornaments. The possibilities are truly endless with VICHOR waterjet cutting.

Our glass designs take on a whole new look by using VICHOR waterjet because we’re able to cut much more complex designs. Before we purchased the waterjet machine, it used to take me hours to cut each design.

Conclusion: Why Choose VICHOR for Your Glass Cutting Needs

The VICHOR Promise: Quality and Customer Satisfaction

As pioneers in the field of waterjet cutting, we at VICHOR are committed to providing our customers with the highest quality products and services. Our advanced technology, coupled with our years of industry experience, ensures precise and efficient glass cutting for various applications. But our commitment doesn’t stop at the sale. We believe in fostering long-term relationships with our customers, providing dedicated after-sales service and support to ensure your satisfaction. With VICHOR, you’re not just buying a waterjet cutting machine; you’re investing in a partnership built on trust and quality.

Two-Year Warranty: Our Confidence in Our Product

Our confidence in the performance and durability of our waterjet cutting machines is reflected in our industry-leading two-year warranty. We stand by the quality of our products, which is why we provide a comprehensive warranty for the entire machine, not just specific parts. This means you can invest in VICHOR with peace of mind, knowing that we’re here to support you in the unlikely event of a product issue.

Contact Us: Learn More about VICHOR Waterjet Cutting

Interested in taking your glass cutting capabilities to the next level with VICHOR waterjet cutting? Contact us today. Our team of knowledgeable professionals is ready to answer your questions, provide additional information, and guide you in selecting the perfect waterjet cutting solution for your specific needs. At VICHOR, we’re not just selling machines; we’re providing comprehensive solutions and building lasting partnerships. Reach out to us today and discover the VICHOR difference.