Waterjet Cutting Food

Unleashing the Power of Modern Food Processing

Introduction to Waterjet Cutting Food with VICHOR Technology

Welcome to the innovative world of waterjet cutting food, a sector experiencing an unprecedented surge in demand due to the unique blend of precision, cleanliness, and efficiency it offers. At the forefront of this trend is VICHOR, a trusted partner in the realm of waterjet food cutting, dedicated to providing state-of-the-art solutions designed to maximize food production businesses’ yield and product quality.

The Growing Demand for Waterjet Cutting in the Food Industry

In recent years, waterjet cutting has gained substantial traction in the food industry, and rightly so. Traditionally, food processing was dominated by blade cutting systems which, although effective, presented certain limitations, including the risk of cross-contamination and time-consuming maintenance needs. Enter waterjet cutting food, a technology that addresses these issues, making it a sought-after solution in an industry where hygiene, efficiency, and accuracy are paramount.

VICHOR: Your Trusted Partner in Waterjet Food Cutting

As a leading provider of waterjet food cutting machines, VICHOR understands the pressing demands of the food industry. Committed to delivering quality and reliability, we stand by our two-year warranty for our entire machine line, ensuring that our customers can depend on our products. Our reputation as a trustworthy partner is further cemented by the real customer information we provide to our new clients, helping them understand the quality of our products and our excellent after-sales service.

Why Choose Waterjet for Food Cutting: Key Benefits and Advantages

The shift towards waterjet cutting in the food industry is not just a trend; it’s backed by substantial advantages that make this technology indispensable in modern food processing.

The Efficiency and Precision of Waterjet Cutting in Food Processing

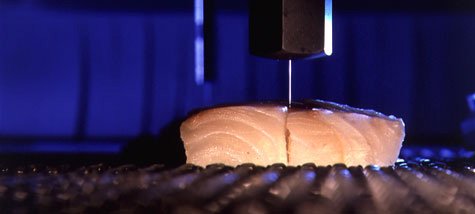

Waterjet cutting employs the power of water—up to 90,000 PSI/6,200 bar—to cut through food products with incredible precision. Even the most delicate or hard and thick foods, like cakes or frozen fish, can be handled with ease by our waterjet food cutting machine. The result? An increase in output, as the cutting process is both faster and more accurate than traditional methods.

A Sanitary Cutting Process: How Waterjet Fights Cross Contamination

Hygiene is a non-negotiable aspect of food processing. Our waterjet cutting process has received USDA approval, signifying a bacteria-free, hygienic cutting method. As it uses pure water for cutting, there is no risk of cross-contamination common in blade cutting systems. The result is a safer, cleaner product, boosting consumer trust in your brand.

Time Saving Food Preparation with Waterjet Technology

Waterjet technology is a major time-saver. With no knife blades involved in the process, there’s no downtime for changing or sharpening blades, translating to uninterrupted production. This has proven particularly beneficial in bakeries where waterjet cutting has practically doubled the yield compared to traditional knife cutting.

Opting for waterjet cutting food technology brings you a myriad of benefits. From boosting productivity to ensuring sanitary processing, this innovation marks a new era in the food industry. VICHOR is here to guide and support you on this exciting journey towards superior food production efficiency.

Understanding the VICHOR Waterjet Food Cutting Process

As pioneers in waterjet food cutting, we at VICHOR believe in offering the best by combining sophisticated technology and innovative techniques. Let’s delve into the intricacies of our process.

The Power of Pure Water: The Essential Component of Waterjet Cutting

The Power of Pure Water: The Essential Component of Waterjet Cutting

The magic behind the remarkable efficiency of our waterjet cutting machines lies in the extraordinary power of pure water. Pressurized to up to 90,000 PSI/6,200 bar, this water jets out in a narrow stream, capable of slicing through any food item with unmatched precision. The absence of any other cutting medium ensures there’s no risk of contamination, making it an impeccable process from a hygiene standpoint.

Diamond Orifice Technology: Enhancing the Life of Waterjet Cutting

A unique feature of our waterjet food cutting machine is the diamond orifice technology. This component, which directs the jet of water, is fashioned from a diamond—making it exceptionally hard-wearing and long-lasting. The waterjet stream is incredibly thin, about the width of a human hair, and it reaches speeds up to 3,000 feet (914 m) per second. This thin stream prevents the food from getting compressed or washed out during the cutting process, preserving its integrity.

How Waterjet Cutting Offers Perfect Portion Control and Improved Shelf Life

Waterjet cutting technology is a game-changer when it comes to portion control and shelf life of food products. The precision offered by waterjet enables perfect portioning, minimizing waste, and maximizing yield. Furthermore, as waterjet cutting doesn’t compress the food, it helps in maintaining the product’s freshness for longer, thereby improving its shelf life.

VICHOR Waterjet: Advantages for Food Production

The VICHOR waterjet cutting food process presents multiple advantages that can elevate your food production processes, leading to an overall improvement in your product quality and profitability.

The Power of Pure Water: FDA Approved and Bacteria-Free

Our waterjet cutting technology is FDA approved, attesting to its adherence to stringent hygiene standards. By using pure water for cutting, the process eliminates the potential for bacterial contamination like salmonella. This, in turn, safeguards the consumer’s health and enhances your product’s safety credentials.

VICHOR’s Waterjet Cutting Technology: A Sanitary and Efficient Solution

Waterjet cutting with VICHOR is the epitome of efficiency. Without the need to clean or sharpen cutting tools, downtime is reduced, and productivity is enhanced. Additionally, the fact that it’s a cold cutting method, with no heat or chemicals involved, ensures that your food items retain their quality and nutritional value.

Environmentally Friendly and Safe: VICHOR’s Commitment to Sustainability

At VICHOR, we are committed to sustainable practices. Our waterjet cutting process produces minimal waste, contributing to a cleaner production environment. The absence of airborne dust and contaminants ensures a safer workplace and a cleaner end product. Plus, with waterjet technology being a non-compression cutting method, the food products’ shelf life is extended, reducing food waste and further supporting environmental sustainability.

VICHOR’s waterjet food cutting technology delivers on all fronts—precision, hygiene, efficiency, and sustainability—redefining what’s possible in food production. By integrating our technology, you’re not just keeping up with industry trends; you’re setting new benchmarks.

The Impact of Waterjet Cutting on the Food Industry

The introduction of waterjet cutting has significantly transformed the food industry, bringing remarkable enhancements in quality, productivity, and food safety.

The introduction of waterjet cutting has significantly transformed the food industry, bringing remarkable enhancements in quality, productivity, and food safety.

Revolutionizing Bakeries: Doubling Yields with Waterjet Food Cutting

Waterjet food cutting has proven to be a game-changer in bakeries. Traditional cutting methods often result in product waste and uneven portions, affecting both the yield and the presentation of baked goods. With VICHOR’s waterjet cutting, bakeries have seen their yields double. The precision offered by waterjet ensures every cut is just right, leading to less waste and more uniform portions.

How Waterjet is Improving Portion Control and Shelf Life of Food Products

One of the greatest advantages of waterjet food cutting is its ability to provide precise portion control, which is particularly crucial for businesses that offer pre-packaged food products. With the accuracy of waterjet cutting, businesses can offer consistent portion sizes, enhancing customer satisfaction. Moreover, waterjet cutting, being a non-compression method, preserves the freshness of food products longer, thereby improving their shelf life.

The Future of Waterjet in Food Production: What to Expect

The future of waterjet cutting in food production is promising. Its wide range of benefits—sanitation, efficiency, precision, and sustainability—makes it an essential technology in the continually evolving food industry. As more businesses realize the potential of waterjet food cutting, we anticipate its adoption across various food sectors, further transforming food production and processing practices.

Case Studies: VICHOR’s Success Stories in Waterjet Cutting Food

VICHOR has had the privilege of making a significant impact in various sectors of the food industry. Here are a couple of our success stories:

The Perfect Slice: How Waterjet Technology Revolutionized Pizza Cutting

One of our notable successes is in the pizza industry. Traditional pizza cutting methods often result in uneven slices and crumbled toppings. With the introduction of our waterjet cutting machines, pizzerias have been able to achieve perfectly even slices without disturbing the toppings—a feat previously challenging to accomplish. The outcome is a quality product that looks as good as it tastes, leading to satisfied customers and increased business.

Sweet Precision: Waterjet Cutting in the Confectionery Industry

Our waterjet food cutting machines have also made a significant impact in the confectionery industry. Cutting candies and other sweets require a delicate touch to preserve their shape and integrity, something that traditional cutting methods struggle to achieve. However, with our waterjet technology, confectioneries can cut their sweets with surgical precision, resulting in a more attractive product and reduced waste.

Through these and many other successes, VICHOR’s waterjet food cutting technology continues to revolutionize food production processes, promising a future of unparalleled precision and efficiency.

Choosing the Right Food Waterjet Cutting Machine: VICHOR’s Expertise

Choosing the right waterjet food cutting machine is crucial to your business’ efficiency and profitability. At VICHOR, we’re here to guide you in making this critical decision.

What to Look for in a Waterjet Food Cutting Machine

When it comes to selecting a waterjet food cutting machine, several factors come into play. Key among these are precision, speed, reliability, sanitation, ease of use, and after-sales service. A machine that ticks all these boxes will likely serve your business best, offering a great return on your investment.

Why Choose VICHOR for Your Waterjet Food Cutting Needs

VICHOR’s waterjet food cutting machines stand head and shoulders above the competition, and here’s why. Our machines offer unparalleled precision and speed, ensuring you get the best output from your production process. They’re designed with sanitation in mind, and they’re also easy to operate. Perhaps most importantly, we stand behind our products with a two-year warranty and exceptional after-sales service. With VICHOR, you’re not just buying a machine; you’re investing in a reliable partnership.

Frequently Asked Questions (FAQs) about Waterjet Food Cutting

When considering the move to waterjet food cutting, it’s natural to have questions. Here, we address some of the most commonly asked queries.

Can Waterjet Cutting be used for Frozen Foods?

Absolutely! Waterjet cutting is exceptionally effective for frozen foods. The power and precision of the waterjet can cut through frozen products without any trouble, maintaining the quality and integrity of the food.

Is the Waterjet Cutting Process Safe for Foods?

Indeed, it is. Waterjet cutting is approved by the U.S. Food and Drug Administration. The process uses pure water, eliminating the risk of contamination from blades. The fact that it’s a cold cutting process means there’s no heat involved, so the food’s nutritional content is preserved.

What Types of Foods can be Cut with a Waterjet?

Waterjet food cutting is incredibly versatile and can be used to cut a wide variety of food items. This includes, but is not limited to, fruits and vegetables, meats, bakery items, confectioneries, and even frozen foods. Its adaptability makes it a great choice for many food processing businesses.

How Does Waterjet Compare to Traditional Food Cutting Methods?

Waterjet cutting offers numerous advantages over traditional food cutting methods. It provides precise cuts without deforming or crushing the food product. There’s also no need for blade changes or sharpening, reducing downtime. Plus, it’s a sanitary process that reduces the risk of cross-contamination.

Switching to waterjet food cutting with VICHOR means you’re choosing precision, efficiency, and quality – key ingredients for the success of any food business.