Waterjet Pump Systems

Introduction to VICHOR Waterjet Pumps

Key benefits and advantages of using VICHOR waterjet pumps

VICHOR waterjet pumps are designed to provide businesses with a cutting solution that offers precision, efficiency, and ease of use. Some key benefits and advantages of using our waterjet pumps include:

- Versatility: Our waterjet pumps can cut a wide range of materials, from soft materials like rubber and foam to hard and thick materials like steel and stone, making them suitable for various industries.

- High precision: VICHOR waterjet pumps deliver precise cuts with minimal kerf, ensuring optimal accuracy and minimal material waste.

- Eco-friendly: Waterjet cutting is a cold cutting process, reducing the risk of heat-affected zones, distortion, or material damage, making it an environmentally friendly option.

- Reduced operating costs: Our pumps have been designed to minimize maintenance and consumable costs, ensuring long-term savings for your business.

- Customizable solutions: VICHOR offers a range of waterjet pumps and accessories to cater to your specific industry needs, allowing for tailored cutting solutions.

VICHOR’s commitment to quality and customer satisfaction

At VICHOR, we prioritize quality and customer satisfaction above all else. We understand that the success of your business relies on reliable, high-performing equipment. To ensure the highest standards, we handcraft our high-pressure waterjet cutting pumps, components, and replacement parts on-site, using our team of skilled engineers and machinists. In addition, we provide a comprehensive two-year warranty on our entire range of waterjet pumps, demonstrating our commitment to delivering long-lasting, dependable equipment.

The Extensive Line of VICHOR Waterjet Pumps

Low-cost, self-contained entry-level systems

VICHOR offers a range of low-cost, self-contained entry-level waterjet pump systems perfect for small businesses or those new to waterjet cutting. These systems provide an affordable solution without compromising on quality, making them an ideal option for budget-conscious businesses looking to benefit from waterjet cutting technology.

Advanced, high-powered waterjet pump options

For businesses with more demanding cutting needs, VICHOR offers advanced, high-powered waterjet pump options. These pumps are designed to deliver high-pressure water streams for faster, more efficient cutting. Equipped with our patented intensifier technology, these pumps ensure optimal performance and precision, making them suitable for businesses with large-scale or specialized cutting requirements.

Industry-specific waterjet cutting solutions

Understanding that different industries have unique cutting needs, VICHOR has developed a range of industry-specific waterjet cutting solutions. Our waterjet pumps can be customized with various accessories and configurations to cater to the specific requirements of industries such as aerospace, automotive, stone and tile, metal fabrication, and more. By working closely with our customers, we can create tailored cutting solutions that deliver the best possible results for your business.

| Standard | Professional | Premium | Maximum | |

|---|---|---|---|---|

| Model | WCM-P55 | WCM-P60II | WCM-P60III | WCM-P60IIIx2 |

| Nominal Power Rate | 50hp (37kW) | 50hp (37kW) | 50hp (37kW) | 100hp (75kW) |

| Max. Pressure Range | 55,000psi (3,792bar) | 60,000psi (4,137bar) | 60,000psi (4,137bar) | 60,000psi (4,137bar) |

| Max. Water Flow Rate | 0.98gpm (3.71lpm) | 0.98gpm (3.71lpm) | 1.0gpm (3.79lpm) | 1.90gpm (7.20lpm) |

| Max. Single Orifice Diameter | 0.013” (0.330mm) | 0.013” (0.330mm) | 0.014” (0.356mm) | 0.018” (0.45mm) |

| Length | 68.70” (1,745mm) | 67.52” (1,715mm) | 67.52” (1,715mm) | 82.68” (2,100mm) |

| Width | 41.14” (1,045mm) | 40.75” (1,035mm) | 40.75” (1,035mm) | 50.00” (1,270mm) |

| Height | 53.15” (1,350mm) | 46.89” (1,191mm) | 46.89” (1,191mm) | 55.91” (1,420mm) |

| Weight | 2,646lb (1,200kg) | 2,260lb (1,025kg) | 2,260lb (1,025kg) | 3,748lb (1,700kg) |

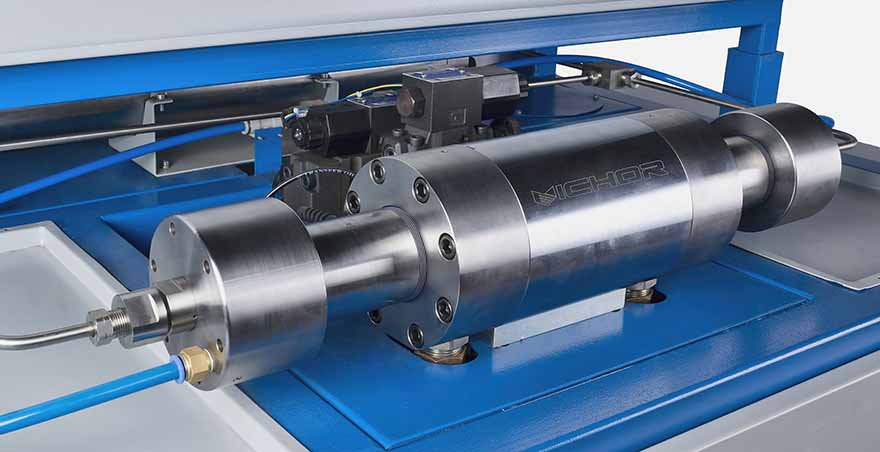

VICHOR’s Patented Intensifier Technology

Importance of intensifier technology in waterjet cutting

Intensifier technology is a crucial component of waterjet cutting systems, responsible for generating the high-pressure water stream required for cutting various materials. The intensifier converts low-pressure water into a high-pressure stream by using a hydraulic piston assembly. This high-pressure water stream is then directed through a cutting nozzle, allowing for precise, accurate cuts.

Unique features and benefits of VICHOR’s patented technology

VICHOR’s patented intensifier technology offers several unique features and benefits that set our waterjet pumps apart from competitors:

- Enhanced performance: Our intensifier technology is designed to provide optimal performance and cutting efficiency, ensuring that your waterjet pump operates at its highest potential.

- Reliability: The use of imported parts for the core of the ultra-high-pressure intensifier ensures that our waterjet pumps remain reliable and long-lasting.

- Low maintenance: VICHOR’s patented technology reduces the need for frequent maintenance, decreasing downtime and associated costs.

- Increased longevity: Our intensifier technology is designed with life-lasting consumable parts, resulting in a longer running life for your waterjet pump and reduced equipment costs.

Longer Running Life and Reduced Operating Costs

Life-lasting consumable parts

VICHOR waterjet pumps are engineered with life-lasting consumable parts, extending the overall lifespan of the equipment and reducing the need for frequent replacements. This not only minimizes downtime but also lowers long-term operating costs for your business.

Energy-efficient hydraulic variable displacement pump

Our waterjet pumps feature a hydraulic variable displacement pump, designed to optimize energy consumption. This innovative technology adjusts the pump’s output according to the cutting requirements, ensuring that the waterjet pump operates at maximum efficiency without wasting energy. As a result, you can enjoy reduced energy costs and a smaller environmental footprint.

Large high-pressure accumulator for pressure stability and enhanced cutting capabilities

VICHOR waterjet pumps are equipped with a large high-pressure accumulator, which ensures pressure stability during the cutting process. This feature enhances the cutting capabilities of the pump, allowing for smoother, more precise cuts and better overall performance. By maintaining consistent pressure levels, the large high-pressure accumulator also reduces the risk of equipment damage and prolongs the life of your waterjet pump.

Ease of Operation and Maintenance

Simplified structure for easy maintenance

VICHOR waterjet pumps are designed with a simplified structure to facilitate easy maintenance, ensuring that your equipment remains in optimal condition with minimal effort. This user-friendly design allows for quick access to key components, reducing downtime and simplifying the maintenance process for your business.

High-reliability through precise electronic commutation

Our waterjet pumps employ precise electronic commutation, which contributes to the high reliability of the equipment. This advanced feature ensures stable and accurate control of the pump’s operation, reducing the risk of errors and ensuring consistent performance over time.

Durable piston rod made of special ceramic materials

The piston rod in VICHOR waterjet pumps is made of special ceramic materials, ensuring high durability and longevity. This robust design not only enhances the overall performance of the pump but also reduces wear and tear, resulting in a longer running life and lower maintenance costs.

PLC (Programmable Logic Controller) for improved stability

VICHOR waterjet pumps utilize a PLC (Programmable Logic Controller) system, which replaces intermediate relays and time relays, offering improved stability and control. The PLC system allows for precise control of the pump’s operation, ensuring consistent performance and reduced risk of equipment failure.

The Importance of Quality Components in Waterjet Pumps

Imported parts for the core of the ultra-high-pressure intensifier

At VICHOR, we understand that the quality of a waterjet pump’s components plays a crucial role in its performance and longevity. That’s why we use imported parts for the core of our ultra-high-pressure intensifiers, ensuring that our pumps remain reliable and long-lasting.

Handcrafted high-pressure waterjet cutting pumps, components, and replacement parts

Our commitment to quality extends to the manufacturing process, as we handcraft our high-pressure waterjet cutting pumps, components, and replacement parts. This attention to detail allows us to maintain strict quality control standards, ensuring that every VICHOR waterjet pump delivers the performance and reliability that our customers expect.

Skilled VICHOR engineers and machinists behind every product

The success of our waterjet pumps can be attributed to the skilled team of engineers and machinists at VICHOR. Their expertise and dedication to producing high-quality products ensure that our waterjet pumps offer unparalleled performance and durability. By investing in our team, we’re able to continually innovate and improve our waterjet pump technology, providing you with cutting solutions that stand the test of time.

Industries Served by VICHOR Waterjet Cutting Machines

Aerospace and automotive

Aerospace and automotive

VICHOR waterjet cutting machines are widely used in the aerospace and automotive industries, where precision and reliability are paramount. Our waterjet pumps provide high-quality cuts on a variety of materials, from lightweight composites to thick metals, ensuring optimal performance for manufacturing aircraft and automotive components.

Stone and tile

The stone and tile industry benefits greatly from the use of VICHOR waterjet cutting machines. Our waterjet pumps allow for intricate designs and patterns to be cut into various stone and tile materials with ease, eliminating the need for traditional cutting methods that may cause damage or require excessive manual labor. This results in faster production times and increased design flexibility for businesses in this sector.

Metal fabrication and more

VICHOR waterjet cutting machines are also employed in metal fabrication, where their precision and versatility are highly valued. The ability to cut various metals with clean, accurate edges makes our waterjet pumps an essential tool for businesses in this industry. Additionally, VICHOR waterjet cutting machines are suitable for a wide range of other applications, including glass cutting, rubber cutting, foam cutting, and more, demonstrating their versatility across numerous industries.

Conclusion: Take Your Business to the Next Level with VICHOR Waterjet Pumps

In conclusion, VICHOR waterjet pumps offer a cutting-edge solution for businesses looking to enhance their cutting processes. With our patented intensifier technology, commitment to quality, and extensive range of customizable options, we’re confident that our waterjet pumps can meet your business’s unique needs. Whether you’re in aerospace, automotive, stone and tile, metal fabrication, or any other industry, VICHOR waterjet pumps can help take your business to the next level. Don’t hesitate to explore the benefits of our waterjet cutting machines and join the thousands of satisfied customers worldwide who rely on VICHOR for their cutting solutions.