– VICHOR, a global leader in advanced waterjet cutting technology, today announced the successful installation of its latest second-generation waterjet tilting table at the facility of ZEBRANO MOBİLYA TEKNOLOJİLERİ A.Ş. in Ankara, Turkey. This innovative system enables safe, one-man operation of large stone slabs, eliminating heavy lifting and delivering rapid ROI through improved safety, efficiency, and material yield. With a 1.2-ton load capacity –

Key Takeaways

- 1.2-Ton Load Capacity: More than triple the industry standard, enabling effortless handling of the largest stone slabs

- One-Man Operation: Eliminates heavy lifting and reduces labor requirements by 60%

- 15+ Year Water Tank Lifespan: Reinforced design outlasts standard configurations by 5-7 years

- Dramatic Safety Improvement: Significantly reduces risk of back injuries and crushing accidents

- Rapid ROI: Immediate cost savings through reduced labor, minimized material waste, and increased productivity

ZEBRANO MOBİLYA TEKNOLOJİLERİ A.Ş. is one of Turkey’s most prestigious furniture brands, globally recognized for its luxury furniture collections and turnkey solutions for architectural projects. With nearly 40 years of experience and a “Luxury Philosophy” approach, ZEBRANO serves high-end residential and commercial projects worldwide. Their choice of VICHOR’s second-generation waterjet tilting table reflects their commitment to precision, safety, and long-term value in their manufacturing operations.

The new system installed at ZEBRANO is a complete VICHOR solution, comprising four seamlessly integrated components:

-

WCM-P60IV Intensifier Pump: Delivering 60,000 PSI with Hypertherm core components and an industry-first 3-year warranty.

-

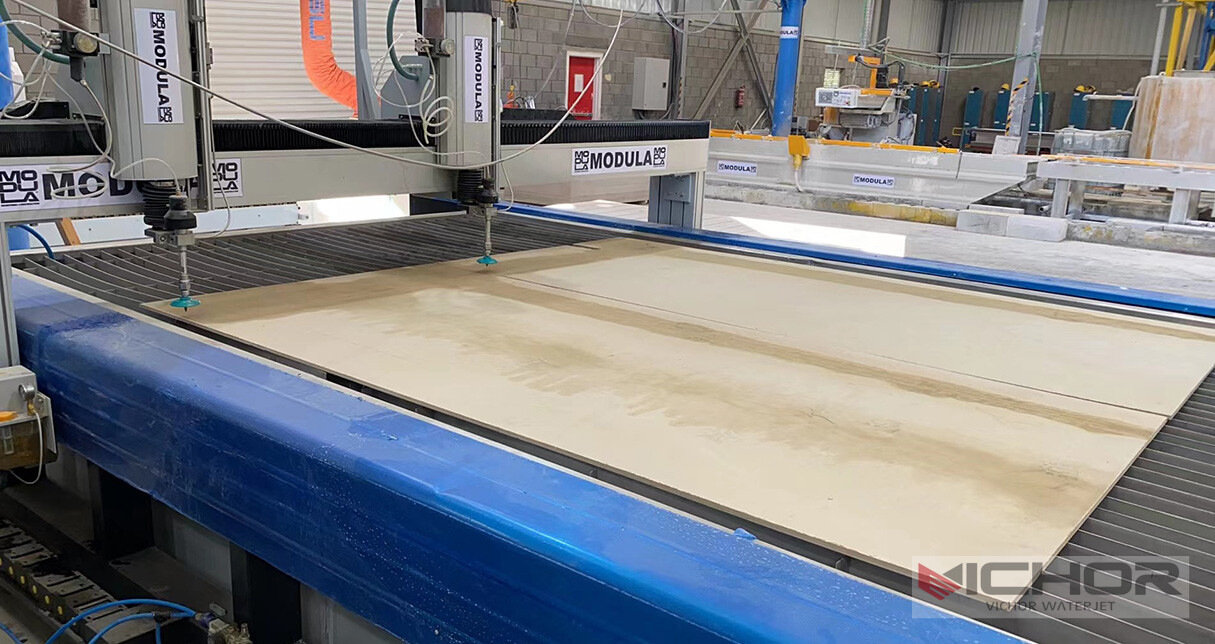

WCM-T4020P Cutting Table: A second-generation tilting table with a 1.2-ton capacity, featuring THK guides and HIWIN ball screws.

-

A5CIII A/C 5-Axis Cutting Head: A proprietary design offering the industry’s largest rotation angle for complex cuts.

-

WCM-NC100 Control System

Labor-Intensive Process: Loading large stone slabs traditionally requires multiple workers to manually lift and position heavy materials. This process demands careful coordination and significant physical effort, creating substantial risk of musculoskeletal injuries.

Safety Concerns: Manual handling of heavy stone slabs poses serious safety risks. Workers must perform awkward lifts and carries, often requiring forklift assistance for larger pieces. The risk of crushing injuries, back strain, and material slippage creates a hazardous work environment.

Material Damage Risk: Without proper tilting equipment, unloading finished pieces—especially large slabs—requires flat-carrying by multiple workers. This manual handling method can result in significant material damage, including cracking and chipping, which directly impacts profitability.

In contrast, VICHOR’s waterjet tilting table is designed for a safe and easy one-man operation, effectively eliminating heavy lifting

How Does Second-Generation Tilting Technology Work?

WCM-T4020P cutting table is the centerpiece of VICHOR’s second-generation tilting table technology. It incorporates significant engineering improvements over standard designs and is built with substantially heavier-duty materials throughout. To ensure maximum precision and reliability, the table is engineered with world-class components, including THK linear guides from Japan and HIWIN ball screws from Taiwan. These premium components guarantee smooth, accurate movement and exceptional longevity even under continuous heavy use.

reinforced water tank structure

robust 1.2-ton (1,200 kg) load capacity, which is more than triple the industry standard of 350-400 kg. This massive capacity allows a single operator to effortlessly load and unload even the largest and heaviest quartz, marble, or granite slabs. The hydraulic system ensures a smooth, controlled tilt, without risking cracking or damaging the material

| Feature | VICHOR 2nd-Gen Tilting Table | Traditional Method (No Tilting Table) |

|---|---|---|

| Load Capacity | 1,200 kg (1.2 Tons) | Limited by manual lifting |

| Labor Required | One-Man Operation | Multiple Workers |

| Safety Risk | Low: Eliminates heavy lifting | High: Risk of back injuries |

| Material Damage | Minimal: Controlled tilt | High: Risk of cracking/chipping |

| Water Tank Strength | Reinforced design (15+ year lifespan) | Standard design (8-10 year lifespan) |

Real-World Impact at ZEBRANO MOBİLYA

Dramatic Safety Improvement: The system eliminates heavy lifting, creating a fundamentally safer work environment. This significantly reduces the risk of back injuries and other musculoskeletal issues common in the industry. Workers are no longer exposed to the risk of crushing injuries or accidents involving heavy slabs.

Massive Productivity Gains: What once required a team of workers and careful coordination can now be accomplished by a single operator in a fraction of the time. Material handling time has been reduced by approximately 60%, allowing the team to focus on value-added cutting and fabrication tasks.

Reduced Material Waste: The controlled, smooth tilting motion ensures that slabs are handled gently, without risking cracking or damaging the material. This leads to a substantial reduction in material waste, directly improving the bottom line.

Reduced Labor Costs

Technical Specifications

| Specification | Value |

|---|---|

| Model | WCM-T4020P |

| Structural Style | Gantry Tilting Style |

| X and Y Axis Travel | 4,000 × 2,000 mm |

| Z-Axis Travel | 250 mm |

| Control Accuracy | ±0.01 mm |

| Cutting Accuracy | ±0.1 mm |

| X-Axis and Y-Axis Max. Moving Speed | 13,000 mm/min |

| Z-Axis Max. Moving Speed | 1,000 mm/min |

| Load Capacity | 1,200 kg (1.2 Tons) |

| Linear Guides | THK (Japan) |

| Ball Screws | HIWIN (Taiwan) |

See the VICHOR Second-Generation Waterjet Tilting Table in Action

To truly appreciate the revolutionary capabilities of the VICHOR second-generation waterjet tilting table, watch it in action:

Video 1: Effortless One-Man Slab Loading

This demonstration showcases the hydraulic tilting mechanism enabling a one-man operation to handle a large stone slab. Notice the smooth, controlled movement and how it eliminates heavy lifting.

Video 2: Precision Cutting in Progress

Observe the speed and accuracy of the VICHOR gantry waterjet system as it cuts through stone. The combination of the stable gantry structure, powerful WCM-P60IV pump, and advanced 5-axis cutting head delivers exceptional results.

Why Choose VICHOR’s Second-Generation Tilting Table?

This second-generation system represents the culmination of years of customer feedback and engineering refinement. The reinforced construction, high-strength water tank, and 1.2-ton capacity make it the most capable and reliable stone slab loading table in the industry.

Frequently Asked Questions (FAQ)

A waterjet tilting table is a specialized piece of equipment used in stone fabrication and other industries to safely load and unload large, heavy slabs onto a waterjet cutting machine. It features a hydraulic mechanism that tilts the table, allowing a single operator to slide the material into place, eliminating the need for manual lifting. VICHOR’s second-generation tilting table offers a 1.2-ton load capacity, making it ideal for handling the largest quartz, marble, and granite slabs.

How does a tilting table improve safety?

It improves safety by eliminating heavy lifting, which is a primary cause of back injuries and other musculoskeletal issues in the workplace. By enabling a one-man operation, it removes the risks associated with coordinating multiple workers to handle heavy, awkward materials.

What is the load capacity of VICHOR’s tilting table?

VICHOR’s second-generation waterjet tilting table has a load capacity of 1.2 tons (1,200 kg), which is more than three times the industry standard of 350-400 kg. This allows it to handle even the largest and heaviest stone slabs with ease.

What industries use waterjet tilting tables?

The primary industry is stone fabrication, including countertop manufacturers, architectural stone companies, and monument makers. However, they are also used in other industries that handle large, flat, heavy materials, such as metal fabrication and composites.