Comparative Cutting

Waterjet Cutting Comparison With Other Methods

Waterjets can cut any solid material including stone, tile, glass, metal, foam, rubber, plastic, and food. When compared with plasma, laser, and edm – waterjet cutting has distinct advantages.

WATERJET vs. Plasma vs. Laser vs. EDM

In addition to no heat-affected zone, the benefits and applications for waterjet technology are limitless and ever-expanding. In comparison to other cutting technologies:

| Waterjet | Plasma | Laser | EDM | |

| Process | Erosion process: high speed liquid sandpaper | Burning / melting process using high temperature ionized gas arc | Melting process using concentrated laser light beam | Erosion process using electrical discharge |

| Materials | Any material. | Primarily steel, stainless steel and aluminum. | Primarily steel, stainless and aluminum. Can also cut a variety of other materials. | Conductive materials only. |

| Thickness | Up to 24 inches, virtually any material. Z constraint is only limit to thickness. | Up to 2-3 inches, depending on material. | Generally 1 inch or less, depending on materials. | Generally 12 inches or less. |

| Part Accuracy | Up to .001" | Up to .010" | Up to .001" | Up to .0001" |

| Capital Investment | $60k to over $300k | $60k to over $300k | $200K to over $1M | $100k to over $400k |

| Machine Setup | Same setup for all materials | Different setup for different jobs | Different gases and parameters for different jobs | Different wire types for different jobs |

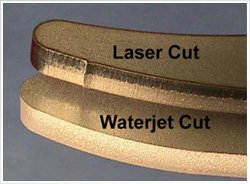

As the grid above illustrates – and the image to the right shows, waterjet cutting technology has clear advantages over other cutting methods.

Green Benefits

Waterjet cutting is a cold-cutting process that eliminates slag deformation and dross waste – unfortunate effects found in plasma and laser cutting processes.

Additionally, both the garnet used in abrasive cutting as well as the water are recycable.