VICHOR WCM-P60IV Pump

20% Efficiency Boost, 430MPa Ultimate Power

VICHOR’s WCM-P60IV intensifier pump, developed through three years of intensive R&D, integrates world-class components from Siemens and Rexroth, achieving 430MPa ultimate cutting pressure and 20% efficiency improvement, delivering revolutionary cutting solutions for high-end industries including aerospace and precision manufacturing.

Efficiency Revolution: 20% Speed Boost

When manufacturing faces increasingly fierce competitive pressure, every minute of efficiency improvement could determine a company’s market position. The launch of VICHOR WCM-P60IV intensifier pump, developed through three years of intensive research and development, addresses this core challenge head-on.

Breakthrough Results at a Glance

- 20% Cutting Efficiency Improvement – Complete more orders in the same timeframe

- 430MPa Ultimate Pressure – Effortlessly tackle the most challenging material cutting tasks

- 380-400MPa Working Pressure Range – Significant improvement over previous generation’s 340-380MPa

- 3-Year Warranty Upgrade – Extended from 2 years to 3 years, reducing your operational risks

Behind these numbers lies direct enhancement of your enterprise competitiveness: faster delivery speeds, lower per-unit costs, and more stable production planning.

How WCM-P60IV Adds Value to Your Business

Direct Economic Benefits

- 20% Production Efficiency Boost: Significantly increase capacity without additional equipment investment

- Reduced Energy Costs: Siemens high-efficiency motor system saves considerable electricity expenses annually

- Lower Maintenance Costs: 3-year complete system warranty + 5-year Hypertherm component warranty dramatically reduces unexpected repair expenses

- Improved Material Utilization: More stable cutting pressure reduces waste generation

Enhanced Competitive Advantage

- Handle More High-Difficulty Orders: 430MPa ultimate pressure enables cutting materials competitors cannot process

- Shortened Delivery Cycles: 20% efficiency improvement directly translates to faster customer response times

- Enhanced Product Quality: Pressure stabilizer ensures every cut achieves consistent high-quality standards

The stability of WCM-P60IV exceeds expectations. Our production efficiency has indeed improved by nearly 20%, and cutting quality is more consistent. This gives us greater confidence when bidding for large projects.

430MPa Ultimate Pressure: How We Achieved It

World-Class Components: Siemens & Rexroth

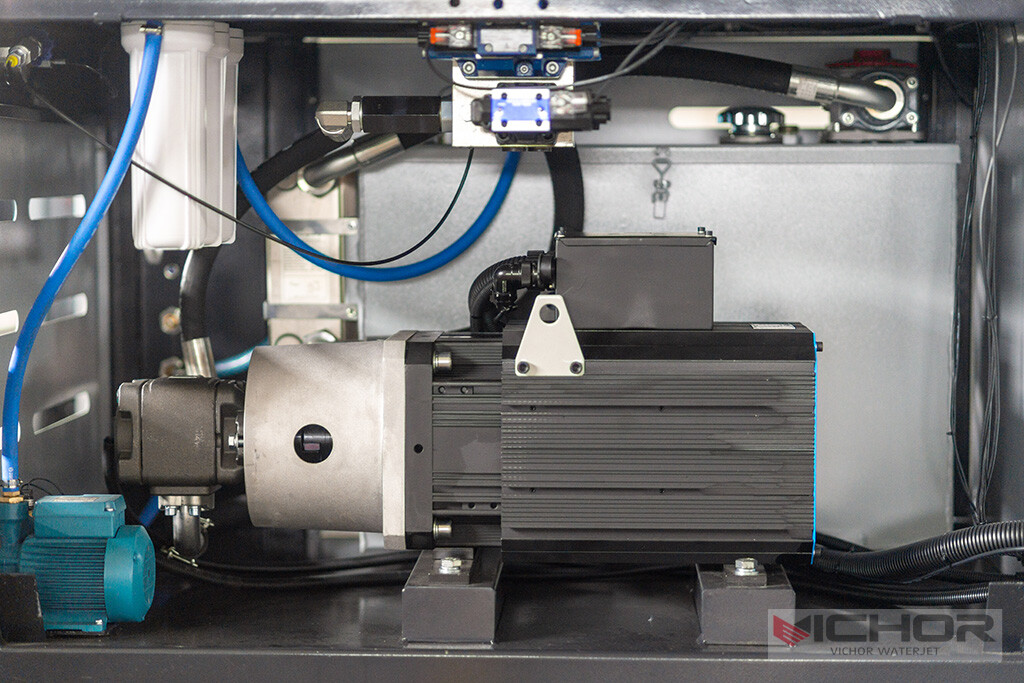

Siemens Original Main Motor

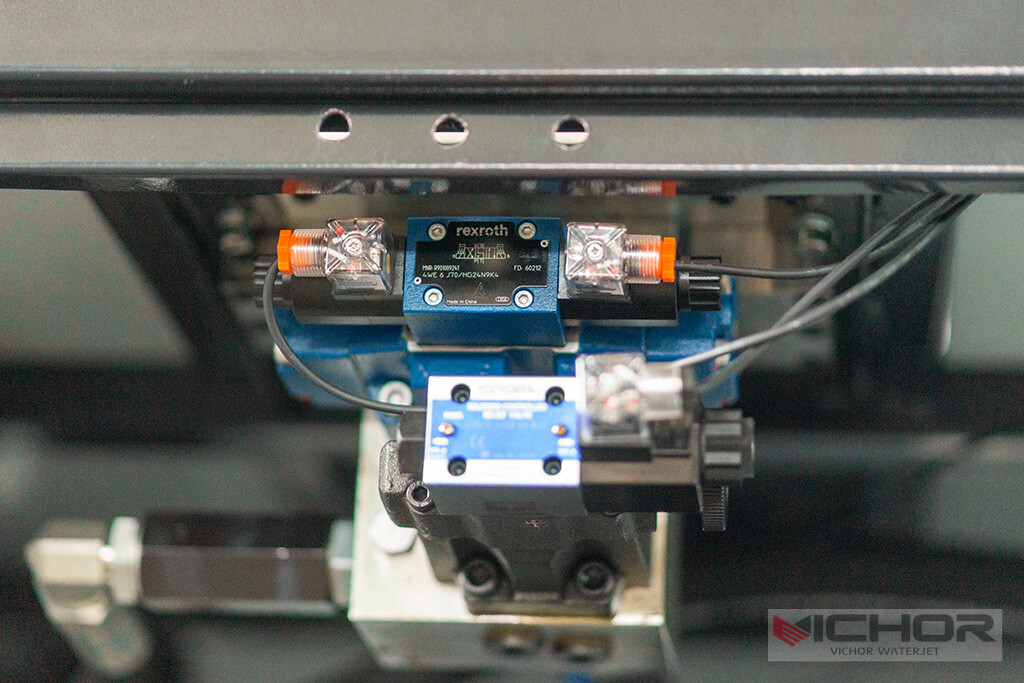

Rexroth Hydraulic System

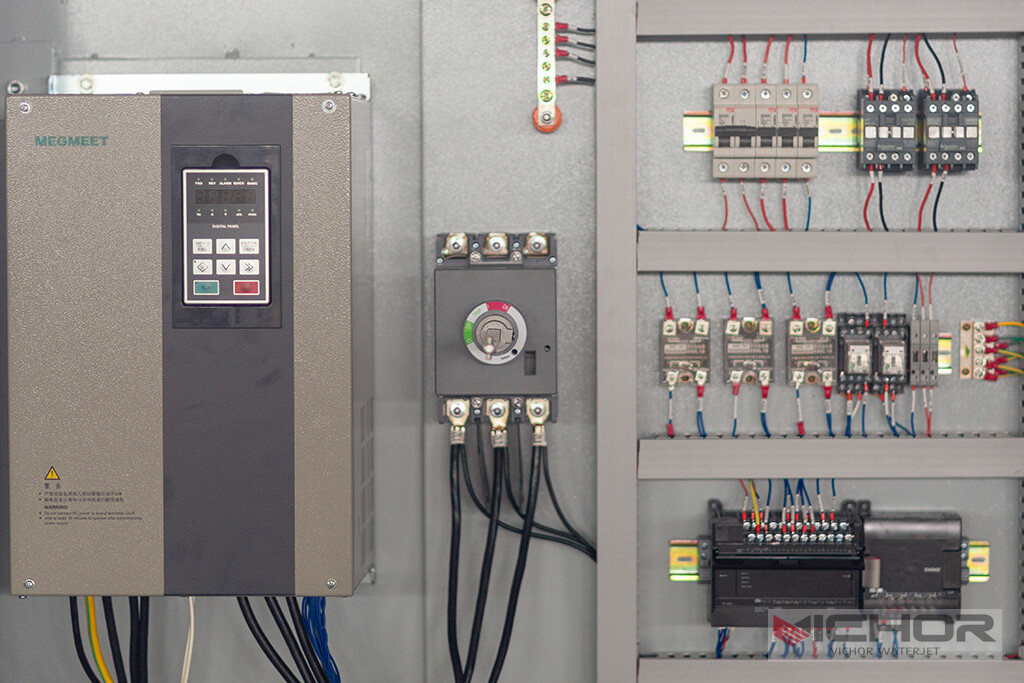

Siemens PLC Intelligent Control

YUKEN Precision Directional Valve

All-New System Design: Fundamental Guarantee of Stability

Comprehensive Structural Framework and Piping System

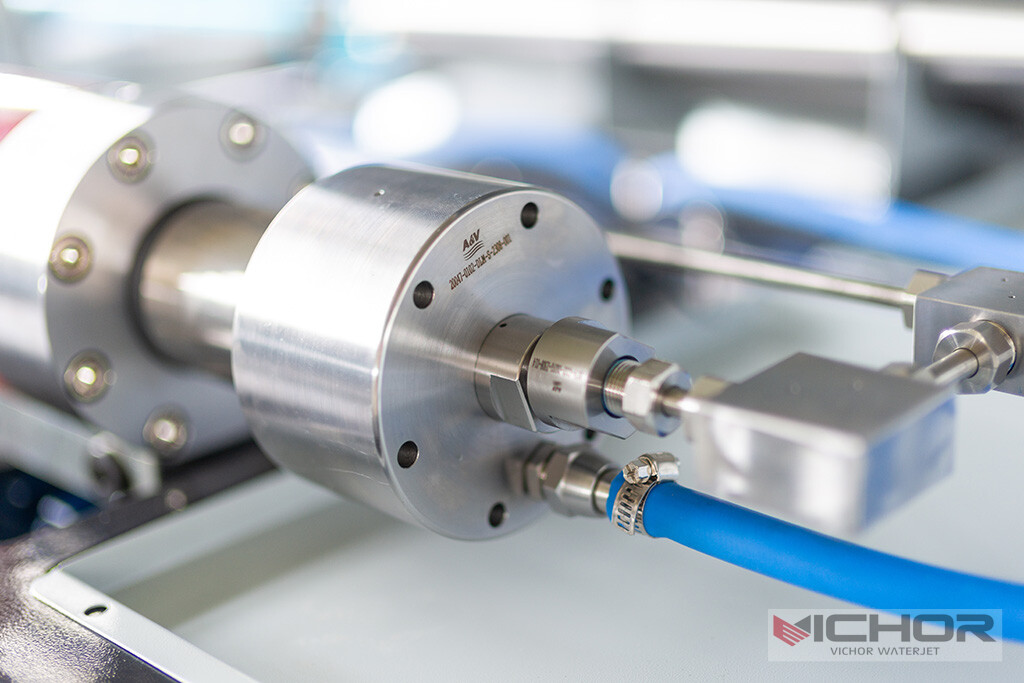

Intensifier Core Upgrades: Precision Details

Large-Capacity Accumulator: Nearly Double the Capacity

Improved End Cap

Optimized Flow Rate

Three Years R&D: 410MPa to 430MPa Breakthrough

Superior Pressure Stability

Hypertherm Core Components: 5-Year Reliability

The WCM-P60IV continues to feature proven Hypertherm intensifier core components, backed by industry-leading 5-year warranty support. These critical components include oil cylinder, high-pressure cylinder, end nut, and piston – all engineered to Hypertherm’s exacting standards for maximum reliability and performance.

Enhanced Warranty: 2 Years to 3 Years Upgrade

Enhanced Warranty Coverage – Upgraded from 2 to 3 Years

The WCM-P60IV comes with significantly enhanced warranty protection, featuring an upgraded 3-year warranty on the complete pump system – a substantial improvement from the previous 2-year coverage. This extended warranty demonstrates our confidence in the enhanced reliability and durability of the new generation system.

Comprehensive Warranty Coverage

- 5-Year Warranty on Hypertherm critical components

- 3-Year Warranty on complete pump system (upgraded from 2 years)

- 20-Year Guarantee on original parts availability

- 12-Hour Response guarantee, including holidays

Technical Specifications Comparison

Specially Suited Applications

- Aerospace Industry: Precision processing of composite materials, titanium alloys, and other high-strength materials

- Precision Stone Processing: Marble inlay work, complex pattern cutting

- Thick Metal Plate Cutting: Industrial material processing of stainless steel, alloy steel, etc.

- Automotive Manufacturing: Precision cutting of high-strength steel plates

- Architectural Decoration: Precision processing of brittle materials like glass and ceramics

For more technical details about WCM-P60IV or to schedule a product demonstration, please contact the VICHOR sales team.