Cutting Bulletproof Glass

The Remarkable Performance of VICHOR Waterjet Explained

Introduction to Bulletproof Glass and the Challenges in Cutting It

Understanding Bulletproof Glass: The Resilient Material

In the world of advanced materials, bulletproof glass, also known as ballistic glass or transparent armor, stands out due to its exceptional strength and resilience. It’s specially designed to resist penetration by projectiles, making it an ideal material for security-focused applications. However, it’s important to note that despite its name, it’s not entirely bulletproof. Instead, it’s built to absorb the energy of the bullet, thereby preventing it from passing through.

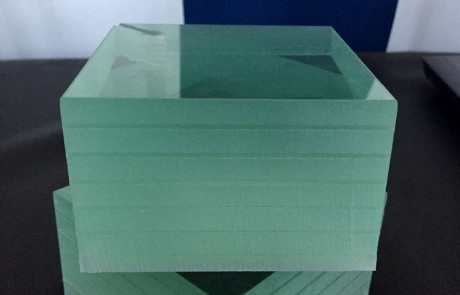

Bulletproof glass is typically a sandwich of multiple layers, composed of hard and soft types of glass. The hard layer offers resistance, while the softer layer gives the material flexibility, allowing it to flex rather than shatter under impact. The thickness of this type of glass varies considerably, ranging from 3/4 to 3 1/2 inches (19 to 89 mm). The thicker the glass, the more resistant it is to penetration.

The Common Difficulties in Cutting Bulletproof Glass

Cutting bulletproof glass presents a unique set of challenges. Traditional cutting methods often fall short, either damaging the material or failing to deliver the required precision. Heat-based methods such as laser or plasma cutting can cause the layers to separate or the glass to crack due to thermal stress. Mechanical methods like sawing can lead to chipping or breakage. Additionally, the cutting process needs to maintain the integrity of the material so it can fulfill its protective function.

VICHOR Waterjet: A Superior Solution for Bulletproof Glass Cutting

The Mechanics of VICHOR Waterjet Cutting Bullet proof Glass

The Mechanics of VICHOR Waterjet Cutting Bullet proof Glass

At VICHOR Waterjet, we have mastered the technique of cutting bullet proof glass with waterjet technology. The process begins with a high-pressure pump, pushing water through a small orifice to create an intense waterjet. Often, an abrasive material like garnet is added to the water stream to enable it to cut through harder materials. As the waterjet makes contact with the bulletproof glass, it erodes the material layer by layer, achieving a precise cut without causing any heat-related damage or distortion.

The Advantages of Using VICHOR Waterjet Cutting for Bulletproof Glass

VICHOR Waterjet cutting offers several distinct advantages when cutting bullet proof glass.

Firstly, it provides unmatched precision, leaving behind smooth, clean edges without chipping or cracking, regardless of the glass’s thickness.

Secondly, it eliminates the heat-affected zone (HAZ) associated with other cutting methods, ensuring the structural integrity and performance of the bulletproof glass remain intact.

Thirdly, it’s incredibly versatile, capable of cutting intricate shapes and patterns that other cutting methods simply can’t achieve.

Lastly, VICHOR Waterjet machines are designed for efficiency and reliability, offering easy maintenance and minimizing downtime for your operations.

Case Study: ARMORED PROTECTION GLASS FACTORY and VICHOR Waterjet

The Challenge Faced by ARMORED PROTECTION GLASS FACTORY

The Challenge Faced by ARMORED PROTECTION GLASS FACTORY

Located in Ras El Khaimah, ARMORED PROTECTION GLASS FACTORY (APG) has over two decades of experience in producing laminated glass. As the demand for their products grew, they faced the challenge of keeping production costs low without compromising on quality. Traditional cutting methods were not only expensive but also caused issues such as thermal stress and material wastage. APG was in dire need of a solution that could maintain high production levels while ensuring the best quality results.

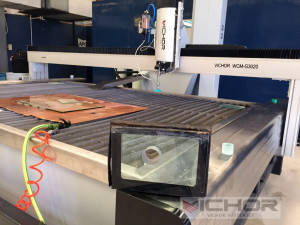

The Solution: VICHOR Waterjet’s Classic Pump WCM-P60II

In their quest for a more cost-effective, efficient, and high-quality cutting solution, APG turned to VICHOR Waterjet. They opted for our classic pump, the WCM-P60II, a model known for its durability, efficiency, and easy maintenance. This pump, paired with our waterjet cutting technology, provided the perfect solution for APG’s bulletproof glass cutting needs.

Results: Improved Production, Reduced Costs, and High-Quality Results

The introduction of VICHOR Waterjet cutting in APG’s production line significantly reduced their operational costs. In addition, the ease of maintenance of the WCM-P60II pump meant less downtime, allowing for a continuous, efficient production process. The high precision and quality of cuts achieved with our waterjet technology also ensured APG could deliver top-notch bulletproof glass to their clients. This collaboration stands as a testament to VICHOR Waterjet’s ability to offer a superior cutting solution for bulletproof glass, underlining our commitment to providing high-quality, cost-effective, and reliable waterjet cutting solutions.

VICHOR Waterjet Cutting Bullet proof Glass: A Detailed Look

The Process of Cutting Bullet proof Glass with VICHOR Waterjet

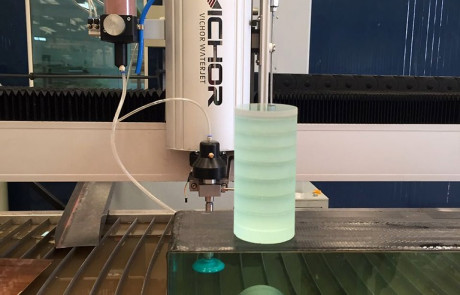

Cutting bullet proof glass with VICHOR Waterjet is an orchestrated blend of technology, precision, and expertise. The process commences with a digital design input into our advanced software system. Following this, our high-pressure pump propels water through a minute nozzle, creating a potent waterjet. When cutting harder materials like bulletproof glass, we introduce fine abrasive particles into this jet, transforming it into an abrasive waterjet.

As the jet makes contact with the bulletproof glass, it erodes the material in a controlled manner, guided by the digital design. This process cuts through the layers of the glass, offering precision that ensures the cut’s quality and the structural integrity of the remaining material.

Cutting 60mm Thick Bullet proof Glass: A Showcase of VICHOR Waterjet’s Capabilities

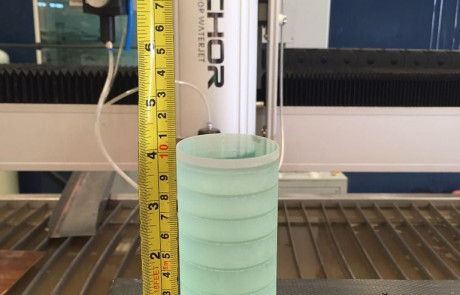

One of our proudest achievements at VICHOR Waterjet is our ability to cut through 60mm thick bulletproof glass. This feat exemplifies the power, precision, and versatility of our waterjet cutting machines. Despite the formidable thickness and strength of this glass, our waterjet cuts through it cleanly and efficiently, maintaining the structural integrity of the glass and delivering a product of the highest quality.

Why VICHOR Waterjet is the Preferred Choice for Businesses

The Exceptional Quality and Reliability of VICHOR Waterjet Machines

Our waterjet cutting machines are engineered with a focus on quality and reliability. We employ advanced manufacturing techniques to ensure the performance and longevity of our machines. Furthermore, our machines are easy to operate and maintain, making them a practical choice for businesses of all sizes.

The Unmatched Two-Year Warranty Offered by VICHOR

At VICHOR Waterjet, we believe in the exceptional quality of our products, and we back this confidence with an unmatched two-year warranty for our entire machine. This warranty, a rare find in the industry, underscores our commitment to customer satisfaction and the confidence we have in our products’ durability and performance.

The Positive Customer Feedback and Reputation

Our reputation among our customers is testament to the quality of our products and services. We are proud to provide real customer information to potential clients, encouraging them to understand our product quality and after-sales service better. Our customers frequently cite our machines’ high quality, our comprehensive warranty, and our exceptional after-sales service as reasons for their satisfaction. With VICHOR Waterjet, you’re choosing a partner committed to your business’s success.

Frequently Asked Questions about Cutting Bullet proof Glass with VICHOR Waterjet

Can VICHOR Waterjet Cut Other Types of Glass and Materials?

Absolutely! The beauty of VICHOR Waterjet lies in its versatility. While we’ve showcased our ability to cut bullet proof glass, our machines can handle a wide range of other materials. From regular glass to metal, composites, ceramics, and even rubber, our waterjet cutting machines can deliver precise, high-quality cuts on nearly any material.

What Makes VICHOR Waterjet Suitable for Cutting Bullet proof Glass?

The suitability of VICHOR Waterjet for cutting bullet proof glass comes from the unique characteristics of waterjet cutting itself. The process is cold, meaning it doesn’t generate heat that could compromise the integrity of the bulletproof glass. It’s also incredibly precise and can cut intricate shapes without causing chipping or cracking. Moreover, our machines are designed to handle the thickness and strength of bulletproof glass, providing consistent, high-quality results.

How Does VICHOR Waterjet Ensure Precision in Cutting Bullet proof Glass?

Precision in cutting bullet proof glass with VICHOR Waterjet comes from a combination of advanced technology and control. We use a high-pressure pump to create a potent waterjet, and the cutting process is guided by a digital design, ensuring the cut follows the exact contours and dimensions required. This digital control, combined with the fine erosive action of the waterjet, ensures a high degree of precision in every cut.

What Makes VICHOR Waterjet’s After-Sales Service Stand Out?

At VICHOR Waterjet, we believe that our relationship with customers extends beyond the point of sale. Our after-sales service is designed to provide you with ongoing support and peace of mind. We offer a comprehensive two-year warranty on our machines, and our experienced team is always ready to help with any maintenance or operational questions you may have. Our commitment to customer satisfaction sets our after-sales service apart.

How Does VICHOR Waterjet Contribute to Cost Savings in Production?

VICHOR Waterjet contributes to cost savings in several ways. Firstly, the precision of waterjet cutting reduces waste, saving on material costs. Secondly, our machines are designed for efficiency, speeding up the production process and reducing labor costs. Lastly, the durability and ease of maintenance of our machines minimize downtime, ensuring your production line keeps moving.

Conclusion: Embrace the Future of Bulletproof Glass Cutting with VICHOR Waterjet

The Unrivaled Benefits of Choosing VICHOR Waterjet for Your Business

Choosing VICHOR Waterjet for your bulletproof glass cutting needs comes with numerous benefits. With our machines, you’re investing in quality, reliability, and precision. You’re partnering with a company that stands behind its products with an unmatched warranty and exceptional after-sales service. And most importantly, you’re choosing a solution that can enhance your productivity and contribute to your bottom line. Embrace the future of bulletproof glass cutting with VICHOR Waterjet — your partner in success.