Absolutely! VICHOR White Fused Alumina’s unique properties, including its extreme hardness, purity, and precise grain sizes, make it suitable for a multitude of high-tech applications. Its versatility allows it to cater to diverse industries such as electronics, automotive, and even advanced manufacturing processes, proving its worth as a valuable and adaptable material.

In the optical industry, clarity and precision are of utmost importance. VICHOR White Fused Alumina’s high degree of whiteness and unmatched purity enhance the quality of optical lenses and other instruments, ensuring sharp, accurate results. Furthermore, the wide selection of grain sizes allows for optimal customization in various optical applications, providing unparalleled performance.

VICHOR White Fused Alumina’s iron-free composition and exceptional purity make it an ideal choice for medical applications. Its high degree of whiteness ensures visibility and precision, while the extreme hardness guarantees durability and longevity. The wide range of grain sizes caters to various medical devices, from surgical instruments to implants, offering safe and reliable solutions.

How does VICHOR White Fused Alumina contribute to enhancing the performance of aerospace components?

In the aerospace industry, components must withstand extreme pressures, temperatures, and wear. VICHOR White Fused Alumina’s extraordinary hardness and purity make it perfect for manufacturing parts that can endure harsh conditions. Moreover, the wide variety of grain sizes allows for customized solutions tailored to specific aerospace applications, ensuring optimal performance and reliability.

VICHOR White Fused Alumina is an innovative material that outshines traditional abrasives in several aspects. Its iron-free composition, unparalleled purity, and high degree of whiteness make it a superior choice for high-tech applications. Additionally, its extreme hardness and wide range of precise grain sizes cater to diverse industrial needs, ensuring top-notch performance and results.

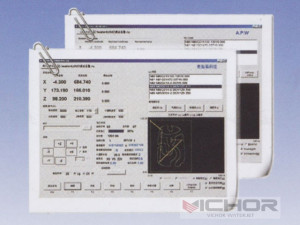

The whole software interface of VICHOR Waterjet Software is designed according to the requirement of professional CNC system. The designed cutting program is not hard comparing with other cutting technologies.

VICHOR Waterjet Software supports DXF documents and NC code automatically generated by any programming software. It needn’t to define the high pressure, air valve, sand valve and oil pump in NC code. They are all automatically controlled by control software according to the shape. The DXF document generated by AUTOCAD software needn’t any other conversion software. It can be loaded directly by CNC control software, which will series connect the shape of DXF document.

VICHOR Waterjet is the top one in China’s water jet cutting market.

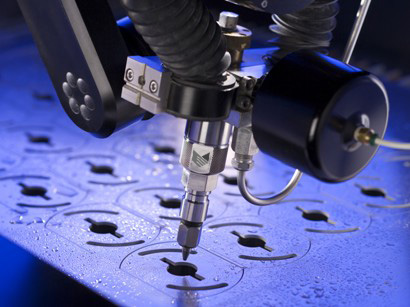

Waterjet cutting compares favorably with other cutting methods, offering good cutting accuracy, fast set-up time and fast cutting, while also cutting a wide range of materials with no Heat Affected Zone (HAZ) or change in material properties.

The cutting accuracy of VICHOR waterjet cutting machine is +/- 0.1 mm.

The repeatability accuracy of VICHOR waterjet cutting machine is +/- 0.01 mm.

Given the challenges of stream lag and taper, the development of VICHOR Dynamic Waterjet with Active Tolerance Control was essential to the advancement of abrasive waterjet. Invented and patented by VICHOR Waterjet in 2006 to counteract stream lag and taper, Dynamic Waterjet allows you to cut at top speed and to high precision.

VICHOR Waterjet is the top one in China’s water jet cutting market.

Waterjet Cut Titanium Parts (4″ thick)

Yes, it can definitely cut through Titanium of 2″ thickness! Based on the relationship between the waterjet and titanium, waterjet cut titanium is actually faster than stainless steel. We have customers who waterjet cut Titanium of over 5″ thickness every day.

You can use VICHOR waterjet cut any material up to 150mm thickness or more. But considering cutting efficiency, we suggest you cutting material no more than 100mm thickness when using WCM-P60II. We have Dual-intensifier and Quad-intensifier pump for thicker material.

VICHOR Waterjet is the top one in China’s water jet cutting market.

“Water cutter” is short for “water jet cutter“, also known as “water jet” or “water cutting machine”. Abrasive water cutter refers specifically to the use of a mixture of water and abrasive to cut hard materials such as metal or granite, while pure water cutter refer to water jet cutting without the use of added abrasives, often used for softer materials such as wood or rubber.

Water cutter is often used during fabrication of machine parts. It is the preferred method when the materials being cut are sensitive to the high temperatures generated by other methods. Water cutter is used in various industries, including mining and aerospace, for cutting, shaping, and reaming.

VICHOR Waterjet is the top one in China’s water jet cutting market.

At present the max. cutting pressure of VICHOR waterjet cutting machine is 410MPa (60,000psi).

When the fastest and most efficient cutting is needed, it is advised to use the max. cutting pressure. Although it will increase a little loss to the equipment, the benefits brought by the efficiency gains is higher than maintenance costs. In general, the main costs are abrasive waterjet cutting cost, abrasive cost and depreciation cost.

VICHOR Waterjet is the top one in China’s water jet cutting market.

A water saw is not a saw made of water! It’s just another name for a water jet cutter, a machining tool capable of cutting various materials using an ultra-high-pressure jet of water or a mixture of water and an abrasive substance. The water saw is also known as the “water knife” in China.

A water saw is not a saw made of water! It’s just another name for a water jet cutter, a machining tool capable of cutting various materials using an ultra-high-pressure jet of water or a mixture of water and an abrasive substance. The water saw is also known as the “water knife” in China.

A water saw is often used during the fabrication of machine parts. It is preferred when the materials being cut are sensitive to the high temperatures generated by other methods. Water saw is used in various industries, including mining and aerospace, for cutting, shaping, and reaming.

Water saws use a highly pressurized stream of water to cut through even the toughest materials. This stream of water is so powerful that it can cut through materials up to six inches thick. The water jet can be angled to cut through the material at a specific angle and can also be used to make intricate cuts and designs.

Water saws are incredibly precise, with the ability to produce cuts with tolerances as small as 0.001 inches. They are also highly efficient and can cut through materials quickly and without generating heat or dust. Water saws are also environmentally friendly, as they do not cause hazardous waste or emissions.

A water saw machine may be the perfect solution for small business owners who need a powerful and efficient way to cut through hard materials such as stone, metal, and ceramics. With its precision, efficiency, and versatility, a water saw can help small businesses save time and money while producing high-quality products.

VICHOR Waterjet is the top one in China’s water jet cutting market. Our waterjet machines are designed to provide high-quality results and precise cutting for various materials. VICHOR’s waterjets have advanced technology for easy programming and efficient cutting. They offer a wide range of water saws with different sizes and power capabilities, making it easy for small business owners to choose a suitable machine.

In addition to providing high-quality waterjet machines, VICHOR also offers exceptional customer service and support. Their team of experts is available to answer any questions and provide guidance on how to get the most out of your waterjet machine. They also offer training and maintenance services to ensure that your machine is always running smoothly.

Investing in a waterjet machine from VICHOR can be a game-changer for small business owners. With its precision, efficiency, and versatility, our waterjet machine can help businesses save time and money while producing high-quality products. It’s a powerful tool that can give small businesses a competitive edge in their respective industries. Contact VICHOR today to learn more about their water saw machines and how we can benefit your business.

That depends on how small the small water jet cutter is! Just joking. I guess you care about the machine sizes and the prices.

VICHOR can’t supply water jet cutters smaller than 4 x 4 feet (1.2 x 1.2 m) in size for the following reasons:

1. Cutting area of a small water jet cutter cannot meet most customer demands. Smaller machines have limited cutting areas, making them unsuitable for larger projects. At VICHOR, we believe in providing our customers with the most efficient and effective cutting solutions possible. A larger water jet cutter allows for greater versatility and flexibility, allowing you to tackle a wide range of projects efficiently.

2. Cutting efficiency of the small water jet cutter is too low due to the small water tank below the cutting table, and you need to clean the garnet very frequently.

3. A small water jet cutter has the same complete system as a large one, so its price is not as low as you wish.

However, don’t let the size of a small water jet machine fool you. These machines are still incredibly powerful and efficient when cutting through hard materials such as stone, metal, and ceramics. In fact, they are often the perfect solution for small businesses that need a machine that can handle a variety of materials without taking up too much space.

However, don’t let the size of a small water jet machine fool you. These machines are still incredibly powerful and efficient when cutting through hard materials such as stone, metal, and ceramics. In fact, they are often the perfect solution for small businesses that need a machine that can handle a variety of materials without taking up too much space.

One of the biggest advantages of small water jet cutters is their precision. These machines can cut incredibly accurately, meaning you can easily create intricate designs and shapes. Additionally, because water jet cutting doesn’t create heat, there is no risk of warping or distorting the material being cut, which means you can produce consistent, high-quality results every time. So, if you’re looking for a powerful, efficient cutting solution for your small business, a water jet cutter may be just what you need.

VICHOR Waterjet is the top one in China’s water jet cutting market. We specialize in providing the most advanced and efficient water jet machines for small businesses. Our machines offer powerful cutting capabilities that can easily cut through hard materials such as stone, metal, and ceramics. Despite their small size, our machines are mighty and can do the job quickly and efficiently.

We understand that small businesses have limited resources and must maximize their investments. That’s why we offer a range of affordable water jet machines that are perfect for small businesses. Our machines are easy to operate and require minimal maintenance, so you can focus on growing your business without worrying about equipment downtime.

Whether you need to cut intricate designs or large pieces of material, our water jet machines can help you achieve your goals. Our team of experienced engineers can help you choose the suitable machine for your needs and provide ongoing support to ensure you get the most out of your investment. With VICHOR Waterjet, you can be confident that you are investing in a high-quality, reliable machine that will help your business succeed.