Custom Waterjet Cutting: Precision Solutions for Complex Materials & Designs

In today’s demanding manufacturing landscape, where innovation pushes the boundaries of material science and design complexity, finding a fabrication method that can keep pace is crucial. Enter custom waterjet cutting – a technology that stands out for its unparalleled versatility, precision, and material compatibility. Unlike many traditional cutting methods, custom waterjet cutting imposes minimal stress on materials, produces no heat-affected zones, and can handle an astonishingly diverse range of substances. This article delves deep into the world of custom waterjet cutting, exploring its technology, advantages, applications, and why it’s often the go-to solution for intricate and demanding projects.

1. Understanding the Technology: Pure Water vs. Abrasive Waterjet

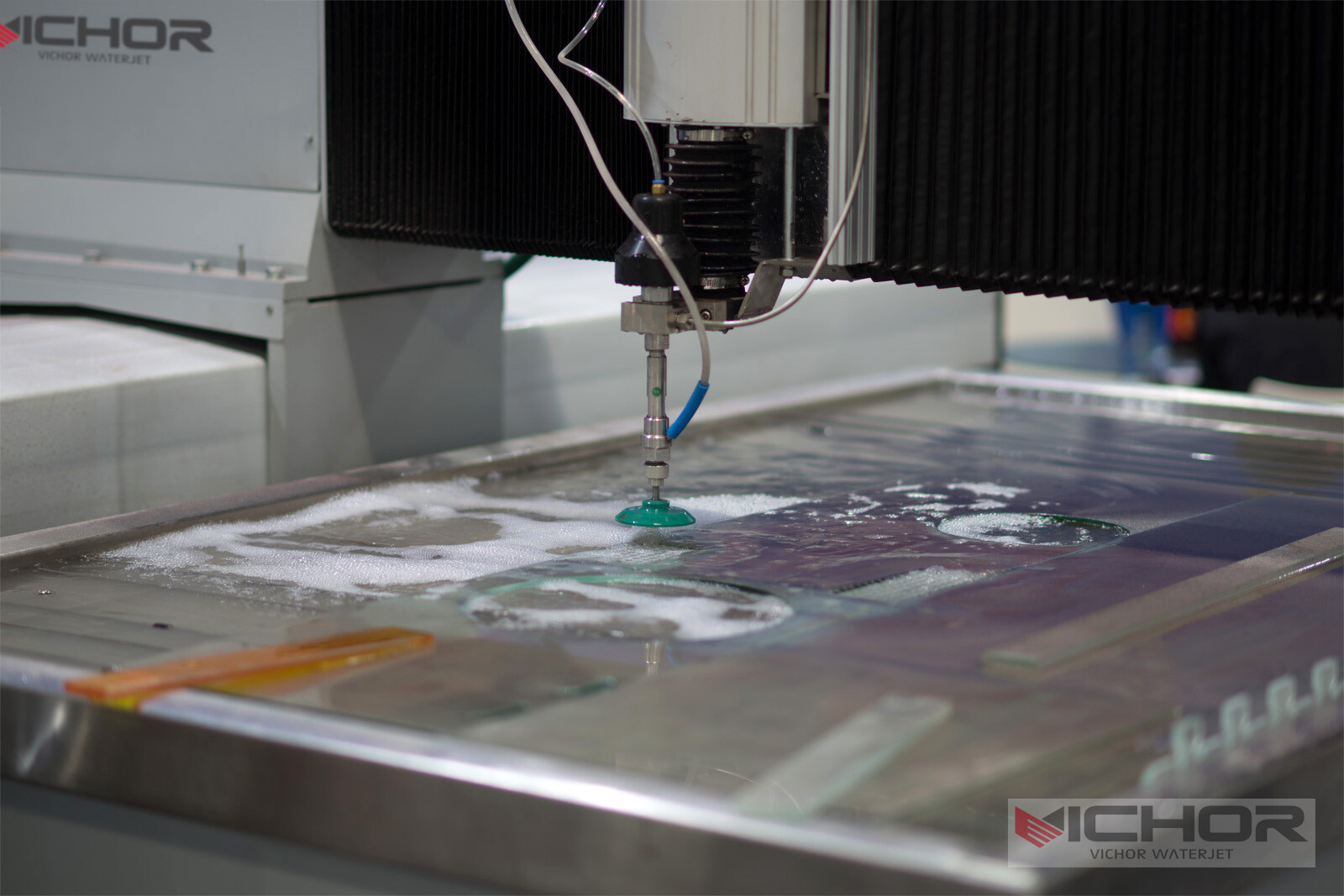

At its core, custom waterjet cutting utilizes an incredibly high-pressure stream of water, or water mixed with abrasive particles, to cut through material. This process begins with a high-pressure pump, typically intensifier pump technology, which pressurizes ordinary tap water to extreme levels – often between 60,000 and 90,000 PSI (or even higher). This ultra-high-pressure water is then forced through a tiny orifice, usually made of diamond or sapphire, creating a supersonic jet.

Pure Waterjet Cutting: Used for softer materials like rubber, foam, gaskets, food products, plastics, insulation, carpet, and paper. The pure, high-velocity water stream erodes the material cleanly and precisely without the need for abrasives. This method is exceptionally clean and ideal for applications requiring no contamination.

Abrasive Waterjet Cutting: For cutting harder materials like metals (steel, titanium, aluminum, brass), stone, glass, ceramics, composites, and thick plastics, an abrasive material (typically garnet sand) is introduced into the high-pressure water stream just after it exits the orifice. The water stream accelerates the abrasive particles, creating an extremely powerful erosive force capable of slicing through virtually any material, regardless of hardness. This is the most common form of custom waterjet cutting for industrial applications.

The cutting head is precisely controlled by a CNC (Computer Numerical Control) system, allowing for intricate shapes and designs to be cut with high accuracy directly from CAD/CAM files. This CNC precision is fundamental to delivering true custom waterjet cutting services.

2. Unmatched Material Versatility: Cutting (Almost) Anything

Perhaps the single most significant advantage driving the demand for custom waterjet cutting is its remarkable material versatility. It is truly a “one tool cuts all” solution, eliminating the need for multiple specialized cutting machines.

Metals: From thin foils to thick armor plate (often up to 12 inches or more, depending on the material), waterjet handles stainless steel, tool steel, aluminum, titanium, copper, brass, bronze, Inconel, Hastelloy, and more with ease. There is no heat, so no hardening, warping, or alteration of the material’s inherent properties.

Stone & Tile: Granite, marble, slate, limestone, travertine, porcelain tile, ceramic tile – custom waterjet cutting is indispensable in the architectural and artistic stone industry for intricate countertops, inlays, mosaics, and signage.

Glass: Whether it’s float glass, tempered glass, laminated glass, or bulletproof glass, waterjet cutting provides clean, chip-free edges and complex shapes impossible with traditional glass cutting methods. It’s perfect for decorative panels, partitions, and technical components.

Composites: Fiberglass, carbon fiber, Kevlar, and other layered composites are notoriously difficult to cut without delamination or fraying. The cold-cutting nature of waterjet makes it the ideal process, producing clean edges without damaging the fibers or resin matrix.

Plastics & Polymers: Acrylics, polycarbonate, PVC, HDPE, UHMW, nylon, rubber, foam – waterjet cuts them all cleanly without melting, burning, or releasing toxic fumes.

Exotic & Specialized Materials: Titanium alloys for aerospace, specialized ceramics for electronics, tooling board for molds, food products, even explosive or heat-sensitive materials are all within the realm of custom waterjet cutting.

This ability to switch between vastly different materials without changing the fundamental setup makes custom waterjet cutting incredibly efficient for job shops and manufacturers handling diverse project portfolios.

3. Precision and Edge Quality: The Cold Cutting Advantage

Custom waterjet cutting delivers exceptional precision and high-quality edge finishes, critical factors for many applications:

High Precision: Modern CNC-controlled custom waterjet cutting systems achieve tolerances typically within ±0.003 inches to ±0.005 inches (±0.075 mm to ±0.13 mm) under optimal conditions. This allows for the production of highly complex and intricate parts that fit together perfectly.

Minimal Kerf: The cutting kerf (the width of material removed by the jet) is relatively small, typically ranging from 0.030 inches to 0.050 inches (0.76 mm to 1.27 mm) for abrasive jets. This minimizes material waste, especially important for expensive exotic alloys.

No Heat-Affected Zone (HAZ): This is a game-changer. Unlike laser, plasma, or oxy-fuel cutting, waterjet is a cold cutting process. There is absolutely no heat input into the material being cut. This means:

No hardening, annealing, or microstructural changes in metals.

No warping or thermal distortion, especially critical for thin materials.

No heat-affected zone that can weaken the material or create stress points.

No melted edges or slag on plastics and composites.

Edge Quality: Waterjet produces a smooth, satin-like finish. While a slight taper (wider at the top than the bottom) is inherent to the process, it is predictable and often negligible for most applications, especially in thinner materials. For thicker cuts, advanced techniques like dynamic waterjet control can minimize taper. The absence of burrs (common with milling) or a recast layer (common with thermal cutting) significantly reduces or eliminates secondary finishing operations.

4. Advantages Over Competing Cutting Technologies

Custom waterjet cutting holds distinct advantages when compared to other popular cutting methods:

vs. Laser Cutting: Lasers are fast and precise for thinner metals but struggle with reflective materials (copper, brass, aluminum can be problematic), thick metals (beyond 1 inch becomes inefficient), and non-metals (many plastics melt or burn, stone/glass shatter). Waterjet has no material reflectivity issues, cuts thick materials effectively, and handles virtually all non-metals without thermal damage. Lasers create a significant HAZ.

vs. Plasma Cutting: Plasma is fast and cost-effective for thicker steel but has a wide kerf, significant HAZ, lower precision, and produces a rougher edge requiring finishing. It’s primarily limited to conductive metals. Waterjet offers superior precision, edge quality, no HAZ, and cuts non-conductive materials.

vs. Wire EDM (Electrical Discharge Machining): EDM offers exceptional precision and surface finish but is very slow and only cuts conductive materials. It also requires the part to be submerged in dielectric fluid. Waterjet is significantly faster, cuts non-conductive materials, and doesn’t require submersion.

vs. Milling/Routing: While milling offers 3D capabilities, it generates significant forces, can cause material deformation (especially in thin sheets), produces burrs, and creates heat through friction. Tool wear is a constant factor. Waterjet is a near-zero force process, eliminating deformation concerns, creates no burrs, and produces no heat. There is no tool wear (only orifice and mixing tube wear, which are consumables).

The custom waterjet cutting advantage lies in its unique combination of versatility, cold-cutting capability, and precision, making it the best or only viable option for countless projects.

5. Diverse Applications Across Industries

The capabilities of custom waterjet cutting translate into applications across a vast spectrum of industries:

Aerospace & Defense: Precision cutting of titanium, aluminum, Inconel, and composites for engine components, structural parts, brackets, and armor. The ability to cut exotic alloys without heat damage is critical.

Automotive: Prototyping, gaskets, interior trim (foam, fabric, plastic), fiberglass components, custom brackets, and specialized tooling. Waterjet handles the diverse materials found in modern vehicles.

Architecture & Construction: Intricate metal facades, decorative panels, structural steel components, stone and tile inlays, countertops (especially complex sink cutouts), signage, and artistic features.

Art & Sculpture: Enables artists to realize incredibly detailed designs in metal, stone, glass, wood, and layered materials. The lack of material restrictions is a major boon for creativity.

Electronics: Cutting circuit board substrates, insulators, gaskets, and specialized composites without generating static electricity or thermal stress that can damage sensitive components.

Food Industry: Cutting frozen foods, cakes, pastries, and other products hygienically and with intricate shapes. Pure waterjet is perfect for this.

Industrial Machinery: Manufacturing parts for machines, tools, jigs, fixtures, and wear plates from hardened steels and other tough materials without altering their properties.

Marine: Cutting fiberglass hull components, composite panels, interior fittings, and stainless-steel parts resistant to corrosion.

Medical: Prototyping and production of surgical tools, implants (cut without altering biocompatibility), medical device components (often from plastics and composites), and gaskets.

Mining & Oil & Gas: Cutting hard materials for wear parts, drill components, seals, and gaskets used in harsh environments.

Why Choose Custom Waterjet Cutting?

Opting for custom waterjet cutting services provides tangible benefits:

Design Freedom: Create complex geometries, sharp corners, intricate details, and internal cutouts that are difficult or impossible with other methods.

Reduced Secondary Operations: The high edge quality and lack of HAZ or burrs often eliminate the need for grinding, sanding, or stress-relieving heat treatments, saving time and money.

Material Savings: Nesting software optimizes part layout on the raw material sheet, minimizing waste. The small kerf also contributes to efficiency.

Fast Prototyping & Low-Volume Production: No hard tooling (like dies or molds) is required. Changes to the CAD file can be implemented instantly, making it ideal for prototypes and short runs.

Environmentally Friendly: The process uses water and natural abrasive (garnet). No toxic fumes or gases are produced. Water is often recycled within the system. Used garnet can sometimes be recycled or is inert landfill.

Single-Source Solution: For projects involving multiple different materials, custom waterjet cutting can handle them all on the same machine.

Custom waterjet cutting has cemented its place as an indispensable technology in modern manufacturing and fabrication. Its unique ability to cut virtually any material, regardless of hardness or thickness, without inducing heat damage or mechanical stress, offers unparalleled flexibility. The precision, excellent edge quality, and minimal waste further solidify its advantages. From intricate aerospace components to breathtaking stone sculptures, from hygienic food processing tools to robust mining equipment, custom waterjet cutting provides a solution where other methods fall short. When facing a challenging material, a complex design, or the need for a pristine, stress-free cut, custom waterjet cutting consistently proves to be the intelligent, versatile, and high-quality choice. As technology advances, offering even greater precision, speed, and automation, the reach and impact of custom waterjet cutting will only continue to expand.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read