7 Things to Know Before Buying a Home Waterjet Cutter: Your Ultimate Guide

For makers, hobbyists, and small-scale fabricators, the dream of cutting virtually any material with precision and ease is becoming increasingly accessible. Enter the home waterjet cutter – a powerful, versatile tool once confined to industrial shops, now scaled down for the garage, workshop, or even dedicated hobby room. But is a home waterjet cutter right for you? This comprehensive guide dives deep into seven crucial aspects you need to understand before taking the plunge.

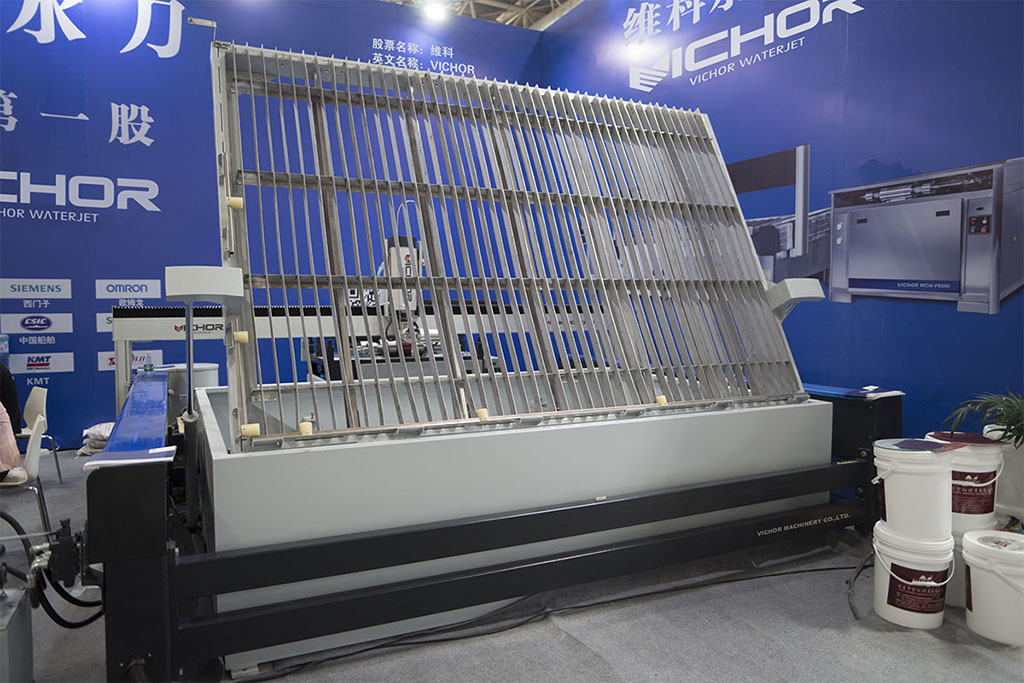

1. What Exactly is a Home Waterjet Cutter & How Does It Work?

At its core, a waterjet cutter uses an incredibly high-pressure stream of water, often mixed with an abrasive garnet sand, to erode material. Think of it as nature’s power washer, amplified thousands of times and focused with laser-like precision.

The Basic Process: A high-pressure pump (often intensifier-based) pressurizes water to 30,000 PSI (over 2,000 Bar) or more. This ultra-high-pressure water is forced through a tiny orifice (typically made of diamond or sapphire), creating a supersonic stream.

Pure vs. Abrasive: For cutting soft materials like rubber, foam, food, or thin plastics, pure water (water-only) is sufficient. For hard materials like metal, stone, glass, tile, or thick composites, an abrasive material (usually garnet) is introduced into the stream just after the orifice, within a mixing tube. This abrasive-laden stream does the actual cutting.

The “Home” Distinction: A home waterjet cutter differs significantly from its industrial cousins. It’s smaller (often benchtop or cabinet-sized), operates at lower pressures (though still very high, typically 30,000-60,000 PSI), has a smaller cutting envelope, and is designed for lower duty cycles. Crucially, it’s engineered for simpler operation, reduced noise (though still significant), and integration into environments without 3-phase industrial power or massive water treatment systems. Think of it as a precision tool for intricate projects and lower-volume production, not cutting thick steel plates all day.

2. Why Consider a Home Waterjet Cutter? Key Benefits & Advantages

The appeal of bringing this technology home is strong, driven by several unique advantages:

Unmatched Material Versatility: This is the home waterjet cutter’s superpower. Cut metals (steel, aluminum, brass, copper), stone, tile, glass, composites (carbon fiber, fiberglass), thick plastics, rubber, foam, leather, ceramics, and even food – all on the same machine without changing tools or processes. No heat-affected zones mean materials retain their original properties.

Exceptional Precision & Edge Quality: Achieve intricate shapes, sharp corners, and fine details that are difficult or impossible with saws, lasers, or plasma cutters. The kerf (width of the cut) is narrow, and the edge finish is typically smooth, often requiring minimal or no secondary finishing.

Cold Cutting Process: Unlike lasers or plasma cutters, waterjet cutting generates virtually no heat. This eliminates warping, hardening, or altering the material’s metallurgical properties around the cut edge. It’s ideal for heat-sensitive materials like plastics, laminates, and certain metals.

Minimal Material Waste: The narrow kerf and precision cutting path optimization software allow for efficient nesting of parts, significantly reducing material scrap compared to many traditional cutting methods.

Reduced Setup & Fixturing: Often, materials can simply be placed on the cutting grid. The non-contact nature of the waterjet stream means complex clamping or fixturing is less frequently required than with milling or routing.

3. Key Features & Components of a Desktop Waterjet System

Understanding the core parts of a home waterjet cutter helps you evaluate different models:

High-Pressure Pump: The heart of the system. Home models primarily use intensifier pumps. They generate pressure by using hydraulic oil to drive a piston that pressurizes water on the other side. Look for reliability, ease of maintenance, and maximum pressure rating (affects cutting speed and material thickness capability).

Cutting Head: Consists of the orifice (creates the water stream), the abrasive metering system (for abrasive cutting), and the mixing tube (where water and abrasive combine). Quality components here are critical for precision and longevity. Quick-change features are a plus.

Cutting Table/Tank: The enclosed workspace where cutting occurs. It holds the water, collects debris, and supports the material. Size defines your maximum work area. Look for robust construction, good sealing, easy access, and effective debris filtration/drainage.

Motion System (X-Y-Z): Typically uses precision linear guides and ballscrews driven by stepper or servo motors. This controls the movement of the cutting head. Accuracy, repeatability, and speed are key factors.

CNC Controller & Software: The “brain” of the operation. Converts design files (DXF, SVG, etc.) into machine toolpaths. User-friendly software is essential for home users. Look for features like nesting, cut sequencing, kerf compensation, and intuitive interfaces. Some systems integrate directly with popular CAD software.

Abrasive Delivery System: A hopper that holds the garnet abrasive and a metering valve that precisely controls the flow into the cutting head. Consistent abrasive flow is vital for cut quality.

Water Filtration & Conditioning: Essential for pump longevity. Pre-filters remove sediment; deionizers or reverse osmosis systems remove dissolved minerals that can damage high-pressure components. Water recycling systems are highly desirable for home use to minimize consumption and waste.

Catch Tank & Filtration: The tank collects the spent water, abrasive, and cut material debris. Filtration systems separate the slurry, allowing water (and sometimes abrasive) to be recycled.

4. What Materials & Projects Can You Tackle with a Home Waterjet Cutter?

The range is truly impressive, opening doors to countless projects:

Metals: Thin to moderately thick sheet metal (aluminum, steel, stainless, brass, copper) for custom brackets, nameplates, decorative art, model parts, jewelry components, knife blanks.

Stone & Tile: Slate, marble, granite, travertine, ceramic, and porcelain tile for custom coasters, backsplashes, intricate mosaics, signage, decorative inlays.

Glass: Cutting thick glass for shelves, dividers, art pieces, or intricate decorative elements. Etching is also possible with pure water.

Plastics & Composites: Acrylic (Plexiglas), polycarbonate, PVC, Delrin, carbon fiber sheets, fiberglass panels. Perfect for custom enclosures, prototypes, RC car parts, signage, templates.

Foam & Rubber: Precision cutting of tooling foam, packaging inserts, EVA foam for cosplay, gaskets, seals, rubber sheets for industrial or artistic use.

Wood & Laminates: While not the primary strength (routers are often better), waterjets can cut thick plywood, MDF, and laminates cleanly, especially useful for intricate patterns or when combining with other materials in a project.

Food: Yes, really! Pure waterjets can cut cakes, cookies, frozen foods, and other soft items with incredible precision for culinary presentations.

Specialty Materials: Leather (intricate patterns), circuit boards (prototyping), textiles (technical fabrics), and more.

5. Choosing the Right Home Waterjet Cutter: Factors to Consider

Selecting the best home waterjet cutter requires careful evaluation:

Budget: This is a significant investment. Prices range from tens of thousands to over $100,000 for capable home/small shop systems. Consider not just the machine cost, but also installation (power, water drain), ongoing consumables (orifice, mixing tubes, garnet, filters), maintenance, and potential water treatment/recycling.

Workspace & Requirements:

Size: Measure your available space meticulously. Include room for the machine, water reservoir, pump unit, compressor (if needed), and operator access.

Power: Most home waterjets require 220-240V single-phase power, but check specific requirements. Amperage draw can be high.

Water Supply & Drain: Need a reliable water source (often filtered/conditioned) and a drain capable of handling the slurry waste (or plan for recycling).

Ventilation/Noise: Waterjets are loud. Enclosed models help, but adequate ventilation is needed for mist and potential odors. Consider soundproofing.

Cutting Envelope (Work Area): What are the largest dimensions of parts you plan to cut? Don’t forget Z-height for material thickness. Common home sizes range from 2’x2′ up to 4’x8′.

Material Thickness & Cutting Speed: Be realistic. Home waterjets excel at thinner materials (e.g., up to 1/2″ steel, 1″ aluminum, 2″ stone). Cutting thicker materials is possible but slow. Understand the speed capabilities for your target materials.

Pump Pressure & Reliability: Higher pressure generally means faster cutting on harder/thicker materials. Research the pump manufacturer’s reputation for reliability and serviceability. Ease of maintenance is crucial.

Software & Control: Is the software intuitive? Does it support your design workflow? Is training included? How easy is it to generate toolpaths?

Build Quality & Support: Look for robust construction, quality linear motion components, and a reputable manufacturer. Investigate warranty terms and the availability (and cost) of technical support and spare parts. A local dealer can be invaluable.

Water Recycling: While an add-on cost, a recycling system drastically reduces water consumption (from 100s of gallons per hour to near zero) and simplifies waste disposal. Highly recommended for home use.

6. Safety, Maintenance & Operating Realities

Operating a home waterjet cutter demands respect and diligence:

High-Pressure Hazards: The water stream is invisible and can cause severe injury. NEVER bypass safety interlocks. Always ensure the cutting head is inside the tank before starting the pump. Wear safety glasses rated for high-pressure fluids.

Noise: Ear protection is mandatory. Waterjets produce significant noise from the pump and the cutting process itself (over 85 dB easily).

Slurry & Debris: The cutting process creates a messy slurry of water, abrasive, and material particles. Enclosed tanks help, but expect cleanup. Proper filtration and disposal are essential. Wear gloves when handling used abrasive or slurry.

Electrical Safety: These machines use high voltage and amperage. Installation should be performed by a qualified electrician. Follow lock-out/tag-out procedures for maintenance.

Regular Maintenance is Non-Negotiable: This isn’t a plug-and-play tool. Expect regular tasks:

Replacing orifice jewels and mixing tubes (wear items).

Changing water filters and DI/RO cartridges.

Lubricating moving parts.

Cleaning the tank, cutting grid, and filtration systems.

Inspecting high-pressure lines and fittings.

Maintaining the abrasive delivery system.

Learning Curve: Operating the CNC software, setting up cuts, understanding feed rates and pressures for different materials, and troubleshooting issues takes time and practice. Factor in a learning period.

7. The Future of Home Waterjet Cutting & Is It Right For You?

The home waterjet cutter market is evolving rapidly. We’re seeing:

Increased Affordability: As technology matures and volumes increase, prices are gradually becoming more accessible.

Improved Compactness & Integration: Designs are getting smaller and more self-contained, including integrated water recycling.

Enhanced Software: More user-friendly interfaces, better simulation, and cloud connectivity are emerging.

Quieter Operation: Advances in pump design and sound dampening are reducing noise levels.

Is a Home Waterjet Cutter Right for YOU?

Answer these questions honestly:

Do you need its unique capabilities? (Cutting diverse, hard materials cold with high precision).

Do you have sufficient projects to justify the cost? (High upfront cost + ongoing consumables).

Do you have the space, power, and water/drain setup?

Are you prepared for the noise, mess, and maintenance?

Do you have the budget, including installation and consumables?

If you answered “yes” to most of these, and your passion or business demands the ultimate in material versatility and precision cutting at home, then a home waterjet cutter could be a revolutionary addition to your workshop. It’s not for the casual hobbyist, but for the dedicated maker, artist, or small-scale fabricator, it unlocks a world of creative and technical possibilities previously unimaginable outside an industrial setting. Carefully weigh the realities against the remarkable potential, and you might find yourself joining the forefront of desktop digital fabrication.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read