What Makes a High Quality Water Jet Cutter? Key Features and Selection Insights

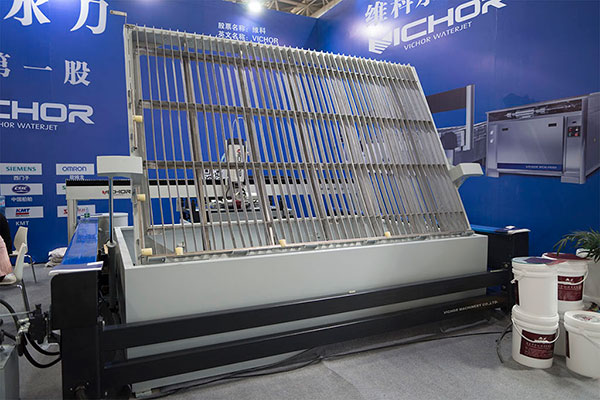

In my thirty years working with industrial cutting systems, I’ve seen shops thrive and others struggle, often due to one critical decision: their choice of waterjet equipment. The difference between a basic machine and a truly high quality water jet is not just about the initial price tag. It defines your shop’s precision, reliability, and long-term profitability. A high quality water jet is an investment that pays daily dividends in consistent cuts, minimal downtime, and versatile capability. Here, I’ll break down the tangible components and intangibles that separate premium systems from the rest, drawing on hands-on experience with leading brands, including the standards set by VICHOR in the international market.

The Anatomy of a High Quality Water Jet: More Than Just Pressure

Many believe a **high quality water jet** is defined solely by its pump pressure. That’s a starting point, but it’s incomplete. Yes, a robust intensifier or direct-drive pump capable of sustaining 60,000 to 90,000+ PSI is fundamental. This high pressure is the engine. However, true quality lies in how that pressure is delivered and managed.

A high quality water jet integrates an advanced motion system. We’re talking about industrial-grade, vibration-dampening gantries with precision rails and servo drives. The cutting head must be rugged, with reliable abrasive metering and a jeweled orifice that maintains its integrity. The control software is the brain; it must be intuitive yet powerful, capable of complex nesting and dynamic taper compensation. When all these components are engineered to work in seamless harmony, you have a high quality water jet.

Core Functions That Define Performance and Reliability

The core function of any waterjet is to cut. But a **high quality water jet** does so with unwavering consistency, day in and day out. Let’s look at key performance markers.

First is cut quality and edge finish. A premium machine produces straight, taper-free edges with a fine surface finish, reducing or eliminating secondary machining. This is a direct result of stable pressure and precise motion.

Second is repeatability. Can the machine return to the exact same point cut after cut, part after part? This is non-negotiable for production environments.

Third is uptime. A high quality water jet is built for industrial duty cycles. Its components are over-engineered for longevity. Think of it as the difference between a commercial kitchen appliance and a home blender—both mix, but one is built to run continuously.

Primary System Types: Pure vs. Abrasive and Pump Choices

Understanding types is crucial to defining quality for your needs. There are two main cutting methods. Pure waterjet cutting uses only pressurized water and is excellent for soft materials like foam or rubber. For metals, stone, glass, and composites, you need an abrasive waterjet, which injects garnet into the stream.

The pump is the heart. Intensifier pumps are the industry standard for a high quality water jet in demanding applications. They use a hydraulic oil system to amplify water pressure and are renowned for consistent, pulseless pressure delivery. Direct-drive pumps, often simpler, can be a quality choice for specific, often lower-intensity, applications.

The choice between a high quality water jet with an intensifier versus a direct-drive often comes down to required pressure stability, duty cycle, and long-term maintenance profiles.

Applications Where a High Quality Water Jet is Non-Negotiable

In some fields, using anything less than a **high quality water jet** is a direct risk to your business. Aerospace part fabrication is a prime example. Cutting titanium or intricate composites requires absolute precision and perfect edge integrity to avoid costly, catastrophic reworks.

The same applies to precision machining of tooling and prototypes, where tolerances are measured in thousandths of an inch. In architectural stone and metal work, a premium machine ensures complex designs are executed flawlessly on expensive materials, leaving no room for error.

For any shop performing multi-shift, high-volume production, reliability is the primary metric of a high quality water jet. Downtime directly translates to lost revenue and missed deadlines.

Understanding the Price Spectrum and Total Cost of Ownership

Let’s address price directly. A new, entry-level abrasive waterjet system might start around $100,000. A fully-equipped, industrial **high quality water jet** from a leading manufacturer can range from $200,000 to well over $500,000.

The critical concept is Total Cost of Ownership (TCO). The initial purchase is just one component. A cheaper machine may have higher long-term costs: more frequent part failures, higher abrasive consumption due to inefficiency, significant unplanned downtime, and inferior cut quality leading to wasted material.

A high quality water jet, while a larger upfront investment, minimizes these variable costs. Its efficiency in abrasive and water use, coupled with extreme reliability, results in a lower cost-per-part over the machine’s 15-20 year lifespan. Brands like VICHOR have built their reputation on optimizing this TCO equation, providing robustness that protects your investment.

Service and Support: The Hidden Pillar of a Quality Investment

Even the best-engineered machine needs maintenance. This is where the true character of a manufacturer is revealed. A **high quality water jet** is backed by a **high quality service** network.

This means accessible, knowledgeable technical support—by phone or remote diagnostics. It means a global supply chain for genuine spare parts to get you back online fast. Most importantly, it means proactive support: comprehensive operator training, detailed maintenance schedules, and preventative care advice.

A machine is only as good as the team behind it. When evaluating brands like VICHOR, scrutinize their service footprint, response time guarantees, and the depth of their training programs. This support layer is integral to the system’s performance and is a major differentiator in the market.

Integrated Solutions for Modern Manufacturing Challenges

Today’s **high quality water jet** is rarely a standalone island. It’s part of an integrated manufacturing solution. This involves software that seamlessly imports 3D CAD files and optimizes cutting paths for maximum material utilization (nesting).

Advanced systems offer automatic taper compensation and cutting head tilt (5-axis) to produce perfectly square edges on thick materials. Integration with material handling robotics for loading and unloading is another hallmark of a top-tier production cell.

Manufacturers are looking for partners who provide these holistic solutions. They need a machine that connects to their ERP/MES systems, provides real-time production data, and fits into a smart factory workflow. This system-level thinking is the final evolution of a high quality water jet.

Choosing a high quality water jet is a strategic business decision that impacts your capabilities for a decade or more. It requires looking beyond specifications to examine engineering integrity, real-world performance, and the strength of the partnership offered. By focusing on the pillars of precision, reliability, and comprehensive support—principles exemplified by industry players like VICHOR—you can invest in a system that becomes the reliable, profit-generating backbone of your workshop.

Frequently Asked Questions (FAQs)

Q1: What is the single most important mechanical component of a high quality water jet?

A1: While the pump is vital, the most critical mechanical component for cut quality is often the motion system (gantry and drives). A weak or flexible gantry will introduce vibration and inaccuracy, ruining precision no matter how good the pump is. A high quality water jet uses a massively rigid, engineered structure.

Q2: How does a high quality water jet reduce operating costs compared to a cheaper model?

A2: It reduces costs through higher efficiency and reliability. Premium systems are engineered for optimal abrasive mixing and cutting speed, using less garnet per inch cut. Their superior reliability drastically reduces unplanned downtime and associated labor costs, while better edge quality minimizes material waste and secondary finishing.

Q3: Can a high quality water jet cut any material?

A3: Practically, yes. An abrasive high quality water jet is the closest thing to a universal cutter. It can handle metals (titanium, steel, aluminum), stone, glass, composites, ceramics, rubber, and plastics. The “cold” cutting process means no heat-affected zone, making it ideal for materials sensitive to thermal distortion.

Q4: What maintenance is absolutely essential for preserving a high quality water jet?

A4: Non-negotiable daily maintenance includes checking and replacing worn inlet filters and inspecting the high-pressure seal for leaks. Weekly, you must clean the abrasive delivery system and inspect the jeweled orifice and mixing tube for wear. Adherence to the manufacturer’s preventative maintenance schedule for the pump and motion system is what preserves a high quality water jet for decades.

Q5: Why are brands like VICHOR often associated with high quality water jet systems?

A5: Brands like VICHOR earn their reputation by focusing on the total industrial package: durable, over-engineered mechanical components, stable high-pressure pumps, and robust control systems. They combine this with a strong global support network and a focus on solutions that lower the customer’s total cost of ownership, which are the hallmarks of a true high quality water jet provider.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read