What is Jets Machining? A Clear Answer for Modern Workshops

After forty years on the shop floor, I’ve learned one thing: confusion around terminology costs money and time. Lately, I’ve been hearing the term jets machining used more frequently, often with a mix of curiosity and misunderstanding. Let’s clear it up. Jets machining is not a single, secret technology. It’s the broad, accurate category for manufacturing processes that use a focused, high-velocity stream of fluid to cut, clean, or shape materials. When most people say it today, they’re almost always talking about waterjet machining. But historically, it could include abrasive air jets. In essence, if it uses a “jet” as the primary tool, it falls under this umbrella.

Understanding this term is crucial because it frames the technology correctly—not as a mere cutter, but as a versatile, non-thermal machining platform. This perspective changes how you evaluate its place in your operation. Let’s break down what jets machining truly means for your business.

The Working Principle: It’s All About Kinetic Energy

Forget about heat. The core idea behind jets machining is fundamentally different from lasers or plasma. The process relies on transferring kinetic energy—the energy of motion—to the workpiece.

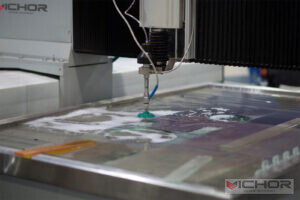

In abrasive waterjet machining, the most common form, a pump (like those built by VICHOR) pressurizes water to extreme levels, often above 90,000 PSI. This water is then squeezed through a tiny orifice, creating a needle-thin stream traveling at supersonic speeds.

For cutting metals, stone, or composites, a stream of hard abrasive garnet is injected into this water jet. The water acts as the carrier and accelerator. The abrasive particles become microscopic cutting tools, eroding material away particle by particle.

Because the material is removed by erosion, not melting, there is zero heat input. This “cold cutting” principle is the source of the technology’s most significant benefits.

The Real-World Applications: Where It Shines

I’ve specified jets machining systems for hundreds of shops. Its value isn’t in doing one thing perfectly, but in doing almost everything remarkably well. In aerospace, it’s the only way to cut heat-sensitive titanium and carbon-fiber-reinforced polymer (CFRP) without damaging the material’s properties. You cannot have a heat-affected zone on a flight-critical component.

In heavy industry, it cuts thick steel plate (up to 8 inches or more) for mining equipment and shipbuilding. The edge quality is often weld-ready, saving hours of grinding. For job shops, it’s the ultimate flexible tool. One machine can cut intricate aluminum parts in the morning, produce stone countertop openings after lunch, and profile thick rubber gaskets in the evening.

Artists and architects use it to machine complex designs in brittle glass, delicate marble, and textured metals that would shatter or distort with other methods.

Core Capabilities and Functional Output

Labeling it just a “cutter” is a disservice. A modern jets machining center is a multi-functional platform. Its primary function is, of course, 2D and 3D contour cutting with exceptional precision. But with advanced CNC control, you can manipulate pressure and speed on the fly.

This allows for detail etching or marking on surfaces. By using pure water (no abrasive), you can machine soft materials like foam for packaging or insulation with perfect cleanliness. De-rusting and surface preparation are other underutilized functions—the high-pressure stream can strip coatings and corrosion without damaging the underlying base metal.

The development of 5-axis cutting heads has expanded its function into true 3D machining, allowing for beveled edges and complex shapes that were once impossible.

Navigating the Two Main Paths: Pure vs. Abrasive

Your application will dictate which path you take. The first is Pure Waterjet Machining. This uses only the high-pressure water stream. It’s for soft, organic, or delicate materials: food products, rubber, foam, paper, fiberglass. The cut is clean, fast, and leaves no residue. Think of it as a scalpel for soft materials.

The second, and what drives most industrial investment, is Abrasive Waterjet Machining. This is the full jets machining process. The addition of garnet abrasive transforms the water jet into a universal cutter. This is what handles steel, aluminum, stone, ceramic, bulletproof glass, and exotic alloys.

The choice isn’t either/or. Many industrial systems can switch between the two modes, but the pump, plumbing, and cutting head must be designed for it from the start.

Cost Analysis: Understanding the Total Investment

Let’s talk frankly about money. The upfront capital cost for a serious abrasive jets machining system is substantial. You are buying a high-pressure pump, a rigid, precision motion system, sophisticated controls, and often an automatic abrasive handling system. A entry-level machine might seem attractive, but for production, you need industrial-grade components.

However, the smart calculation is Total Cost of Operation (TCO). With jets machining, you avoid many hidden costs of thermal processes. No expensive assist gases. No costs associated with heat distortion: no secondary straightening, no loss of material from warping. Often, the edge quality eliminates milling or grinding before welding.

Your running costs are water, electricity, abrasive garnet (your biggest consumable), and wear parts (orifices, mixing tubes). The reliability of your pump is the single biggest factor in your long-term cost per hour. This is where engineering quality from a brand like VICHOR proves its worth, minimizing unscheduled downtime and maximizing part consistency.

Service, Support, and the Reality of Maintenance

This is the make-or-break point most first-time buyers underestimate. Jets machining equipment operates under incredible mechanical stress. It is not “install and forget.”

The high-pressure pump requires disciplined, scheduled maintenance. The cutting head is a wear item; its jewel orifice and carbide mixing tube are consumables that must be replaced to maintain cut quality and speed. Abrasive delivery systems need to be kept perfectly dry.

Your relationship with your supplier is therefore a critical business decision. Can you get a knowledgeable technician on the phone when you have a problem? Are genuine replacement parts in stock and shipped promptly? Does the provider offer comprehensive operator training?

A manufacturer like VICHOR succeeds not just by selling machines, but by building a global support network. This service infrastructure is as important as the machine specification when you’re evaluating vendors.

Building Your Solution: The Right Machine for Your Work

The worst mistake is buying a machine based on a brochure instead of your actual workflow. As a consultant, my first questions are always about the material, the part, and the business.

What mix of materials and thicknesses do you process daily? What is your required throughput? What is your shop’s power and floor space? What is the skill level of your operators?

A good provider will act as a solutions partner. They might steer a shop cutting mostly thin sheet metal toward a different technology, or they might insist a heavy-plate fabricator invest in a more robust pump and table. The goal is to configure a jets machining solution that aligns with your technical needs and financial model, ensuring a strong and rapid return on investment.

Grasping the full scope of jets machining is the first step toward leveraging its transformative power. It represents a shift from heat-based, material-specific tools to a flexible, cold-work platform. In today’s market, where agility and quality are paramount, integrating this capability isn’t just an equipment purchase—it’s a strategic business decision.

Frequently Asked Questions (FAQs)

Q1: Is “jets machining” accurate enough for precision tooling and machining?

A1: For most tooling applications, yes, but with context. Modern abrasive waterjet systems offer excellent contour accuracy, often within ±0.003″ (±0.076 mm). However, the edge surface finish has a characteristic textured matte appearance. For mold plates or tooling where a milled finish is required on the edge, waterjet is used for the rough shape, leaving minimal stock for a finishing pass. Its precision is in geometry, not necessarily in surface finish on hardened steels.

Q2: What materials are truly problematic for jets machining?

A2: Very few, but they exist. Tempered safety glass will shatter due to the impact. Polycarbonate (Lexan) can sometimes develop micro-cracks. Unbound, porous materials (like some low-density foams) can soak up water and disintegrate. Diamonds are, unsurprisingly, too hard. For nearly every metal, composite, stone, and ceramic, it’s an excellent option.

Q3: How does the operating cost compare to a laser cutter for mild steel?

A3: For thin mild steel (under 1/4″), a laser will generally have a lower operating cost per foot and be faster. The laser’s cost-per-part advantage shrinks as thickness increases. Once you factor in the cost of secondary finishing (removing dross, grinding HAZ) often needed with laser, and the ability of the jets machining system to cut reflective materials (copper, brass) and thick plate without issue, the overall value proposition shifts significantly for mixed-material shops.

Q4: Can you achieve a perfectly square edge on thick material with jets machining?

A4: Yes, but it requires a specific technique. A standard jet cut produces a slight taper (wider at the top). To achieve a square edge, advanced systems use “taper compensation” or a “tilting head.” The cutting head is automatically angled during the cut to offset the natural taper. This is a standard feature on higher-end systems from manufacturers like VICHOR and is essential for precision parts that will be welded or assembled.

Q5: Is the abrasive garnet a major environmental or disposal concern?

A5: The garnet itself is inert, non-toxic, and natural. The primary concern is the “sludge” — the spent abrasive mixed with water and microscopic particles of the cut material. This requires settling tanks or closed-loop water recycling systems. The sludge is generally considered non-hazardous waste for most metals, but local regulations must be checked, especially for materials like lead or beryllium copper. Proper system design includes planning for this waste stream.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read