What is a Hydro Jet Cutting Machine? Exploring the Power of Water

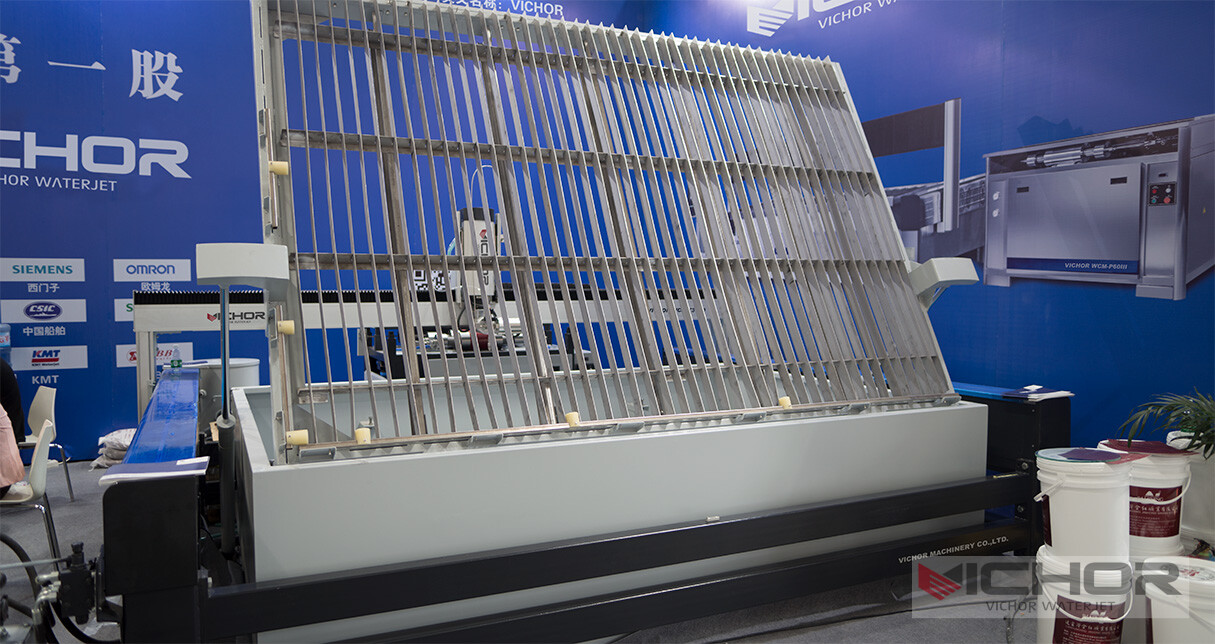

In the world of precision manufacturing and fabrication, few tools are as versatile and powerful as the hydro jet cutting machine. Also known as waterjet cutting, this technology harnesses the incredible force of water, often mixed with abrasive materials, to slice through a vast array of materials with unmatched precision. From intricate metal designs to delicate stone mosaics, the applications are nearly limitless. This article dives deep into how these machines work, their numerous benefits, and why a brand like VICHOR is making waves in this innovative industry. Whether you’re a seasoned engineer or a curious hobbyist, understanding this technology could revolutionize your approach to cutting.

How Does a Hydro Jet Cutting Machine Work? The Science of Precision

At its core, the principle behind a hydro jet cutting machine is elegantly simple yet powerfully effective. It operates on the fundamentals of erosion, but accelerated to an industrial level. The process begins with a high-pressure pump, which is the heart of the system. This pump pressurizes ordinary water to extreme levels, typically between 60,000 and 90,000 Pounds per Square Inch (PSI).

This ultra-high-pressure water is then forced through a tiny orifice, usually made of sapphire or diamond, in a nozzle. This focused jet of water exits the nozzle at speeds up to three times the speed of sound. For cutting harder materials like metals, stones, or ceramics, a granular abrasive (often garnet) is introduced into the stream right after the nozzle. This mixture of super-fast water and abrasive particles creates a relentless erosive stream that cuts through material with pinpoint accuracy.

The hydro jet cutting machine is typically controlled by a computer numerical control (CNC) system, which guides the cutting head along a programmed path. This allows for incredibly complex and detailed shapes to be cut from digital designs with minimal human intervention, ensuring repeatability and perfection on every piece.

Top Advantages of Using a Hydro Jet Cutter Over Other Methods

Why choose a hydro jet cutting machine over laser, plasma, or mechanical cutting tools? The advantages are significant and cater to a wide range of manufacturing needs.

Cold Cutting Process: Unlike thermal cutting methods (laser or plasma), waterjet cutting is a cold process. It generates virtually no heat-affected zone (HAZ). This means the structural integrity of the material remains unchanged; there is no warping, hardening, or altering of the material’s intrinsic properties. This is crucial for materials like tool steel or aluminum where heat can cause critical weaknesses.

Material Versatility: This is perhaps its greatest strength. A single hydro jet cutting machine can cut through metal, stone, glass, rubber, foam, composites, titanium, and even food products. There is no need for multiple, specialized cutting systems, making it an incredibly cost-effective solution for job shops that work with diverse materials.

High Precision and No Tool Wear: The abrasive waterjet stream is consistent and does not dull like a mechanical blade. It produces smooth cuts with a very narrow kerf (the width of the cut), often with tolerances within ±0.005 inches. This allows for intricate details and minimizes material waste.

Environmental Friendliness: The process produces no hazardous fumes or gases. The primary waste product is a slurry of water and abrasive particles, which can be easily settled out and managed. It’s a much cleaner process compared to plasma or laser cutting, which can release toxic vapors, especially when cutting plastics or coated metals.

Minimal Set-Up and Flexibility: With no need for custom tooling or clamps for different materials, setup times are drastically reduced. Changing from cutting half-inch titanium to one-inch marble is as simple as loading a new file and adjusting the feed rate on the CNC control.

Common Applications: Where You’ll Find Hydro Jet Cutting in Action

The versatility of the hydro jet cutting machine has led to its adoption across a stunningly diverse range of industries. Its ability to handle such a wide variety of materials makes it indispensable.

Aerospace and Aviation: Used for cutting intricate components from composites, titanium, aluminum alloys, and other high-strength, heat-sensitive materials used in aircraft and spacecraft.

Architecture and Art: From custom stone inlays and intricate metal facades for buildings to detailed sculptures and art installations, artists and architects use waterjets to bring complex designs to life.

Automotive Industry: Manufacturers use it for cutting interior components like carpets and gaskets, as well as exterior parts like body panels and trim from various materials.

Food Industry: In a surprising application, pure waterjets (without abrasive) are used for cutting cakes, frozen foods, pizza, and poultry. It’s a hygienic, precise, and fast method for portioning food.

Manufacturing and Machine Shops: This is the broadest application, encompassing the cutting of tool parts, prototypes, gaskets, and machinery components from plastics, metals, and rubbers.

Key Considerations When Choosing a Hydro Jet Cutting Machine

Investing in a hydro jet cutting machine is a significant decision. Several factors must be considered to ensure you select the right system for your needs.

Pump Type: There are two main types: direct drive and intensifier pumps. Intensifier pumps are the industry standard, capable of delivering higher and more consistent pressure, which translates to faster cutting speeds and better performance on thick materials. A brand like VICHOR often incorporates robust intensifier pump technology in their systems for reliable, continuous operation.

Cutting Table Size: The size of the machine’s table determines the maximum size of the material you can process. It’s essential to consider both your current and anticipated future needs.

Horsepower (HP): The pump’s horsepower directly correlates to the water pressure it can generate. Higher HP (e.g., 50HP, 100HP) means higher pressure, enabling faster cutting speeds and the ability to tackle thicker, harder materials efficiently.

Control Software: The user interface and capabilities of the CNC software are critical for productivity. Look for intuitive software that supports standard file formats (like .DXF) and offers features like automatic nesting to maximize material usage.

Brand Reputation and Support: Choosing a reputable brand is paramount. VICHOR, for example, has built a reputation for manufacturing durable and precise machines backed by strong technical support, comprehensive training, and readily available spare parts. This ensures minimal downtime and long-term reliability.

Maintaining Your System for Optimal Performance and Longevity

Regular maintenance is key to keeping your hydro jet cutting machine running smoothly and extending its service life. A well-maintained machine ensures consistent cut quality and avoids costly downtime.

Daily Checks: Inspect the abrasive delivery system for clogs, check water levels and filters, and look for any visible leaks in the high-pressure plumbing.

Regular Component Replacement: The intensifier pump contains seals and check valves that are subject to extreme wear. These need to be replaced as part of a scheduled maintenance plan. The cutting nozzle and orifice are also wear items and must be changed periodically to maintain cutting accuracy and pressure.

Water Quality: Using filtered, purified water is not a suggestion—it’s a requirement. Impurities in the water can rapidly damage the high-pressure pump and clog the tiny orifice. Most systems, including those from VICHOR, integrate water purification systems to protect this vital investment.

Abrasive Handling: Ensure your abrasive is stored in a dry environment to prevent clumping, which can block the feed lines. Regularly clean the abrasive hopper and delivery system.

Frequently Asked Questions About Hydro Jet Cutting Machines

Q1: How thick of a material can a hydro jet cutting machine cut?

A: While it can cut very thick materials, practical thickness depends on the material type and the machine’s pressure. An industrial-grade machine can typically cut through over 12 inches of softer materials like foam or plastic and up to 6-8 inches of harder materials like titanium or stainless steel, though cutting speed will decrease significantly with thickness.

Q2: What is the typical tolerance and edge quality?

A: A well-tuned hydro jet cutting machine can hold tolerances of ±0.003″ to ±0.005″. The edge quality is characterized by a slightly matte, smooth finish. There is a slight taper to the cut (wider at the top than the bottom), but this can be minimized with advanced dynamic cutting heads and slower cutting speeds.

Q3: Is it expensive to operate?A: The operational costs are primarily electricity, water, abrasive garnet, and routine maintenance parts. While the abrasive is a consumable cost, it is generally more cost-effective than the tooling costs associated with mechanical cutting or the gas costs for plasma. The overall cost-per-part is often lower due to reduced secondary processing needs.

Q4: How loud is a waterjet?

A: The cutting process itself is very loud, often requiring operators to wear hearing protection. The pump enclosure also contributes to noise. Modern systems from manufacturers like VICHOR are designed with sound-dampening enclosures to reduce noise levels in the workshop.

Q5: Can it really cut anything?

A: While extremely versatile, there are a few materials that are not well-suited for waterjet cutting. Tempered glass will shatter because the process disrupts its internal stresses. Likewise, certain hardened ceramics and diamonds are too hard to be cut efficiently. However, the list of materials it can cut is vastly longer than the list it cannot.

In conclusion, the hydro jet cutting machine stands as a testament to the power of innovation, transforming a simple natural element into a tool of immense industrial capability. Its cold-cutting nature, unmatched versatility, and precision make it a valuable asset in any modern fabrication environment. For businesses seeking reliability and performance, partnering with an established brand like VICHOR can provide the technology and support needed to stay competitive and push the boundaries of what is possible in manufacturing and design.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read