Wet Jet Cutter: 7 Critical Aspects for Superior Cutting Performance

In the world of modern manufacturing and fabrication, precision and efficiency are paramount. Among the various cutting technologies available, the wet jet cutter stands out as a versatile and powerful tool. This high-pressure water jet system, often enhanced with abrasives, enables clean, accurate cuts across a wide range of materials without generating heat-affected zones. Whether you’re in aerospace, automotive, or artisanal crafts, understanding the wet jet cutter can revolutionize your workflow. This article delves into seven essential aspects of the wet jet cutter, providing a comprehensive overview to help you harness its full potential. From its fundamental workings to practical maintenance tips, we’ll explore how this technology can elevate your cutting processes, ensuring you make informed decisions for your projects.

What is a Wet Jet Cutter?

A wet jet cutter, commonly referred to as a water jet cutter, is an industrial tool that utilizes a high-pressure stream of water, sometimes mixed with abrasive substances, to cut through materials. The core principle involves pressurizing water to extreme levels—often up to 60,000 psi or more—and directing it through a narrow nozzle to create a focused jet. This jet moves at supersonic speeds, enabling it to slice through metals, composites, stone, glass, and even delicate materials like foam or rubber. Unlike thermal cutting methods such as laser or plasma, the wet jet cutter operates without generating heat, which prevents material distortion, hardening, or toxic fume production. This makes it an ideal choice for applications where precision and material integrity are critical. The versatility of the wet jet cutter allows it to handle intricate designs and thick materials, making it a staple in industries ranging from architecture to electronics. By leveraging the natural properties of water and abrasives, this tool offers a environmentally friendly alternative that minimizes waste and energy consumption, aligning with sustainable manufacturing practices.

How a Wet Jet Cutter Works

The operation of a wet jet cutter involves a sophisticated process that begins with water intake and culminates in precise material cutting. First, water is sourced from a standard supply and filtered to remove impurities that could damage the system. It then enters an intensifier pump, which pressurizes the water to levels between 30,000 and 90,000 psi. This high-pressure water is channeled through high-strength tubing to a cutting head, where it passes through a small orifice—typically made of sapphire or diamond—to form a coherent jet. In abrasive wet jet cutting, garnet or other abrasives are introduced into the stream via a mixing chamber, enhancing the cutting power for harder materials. The abrasive-laden jet exits the nozzle at speeds exceeding 800 meters per second, effectively eroding the material along a programmed path controlled by CNC (Computer Numerical Control) systems. This computer-guided accuracy allows for complex shapes and tight tolerances, often as fine as 0.1 mm. The entire process is cooled by the water, eliminating thermal stress and making the wet jet cutter suitable for heat-sensitive materials. Regular monitoring of pressure levels and nozzle wear ensures consistent performance, highlighting the importance of proper setup and calibration in achieving optimal results with a wet jet cutter.

Key Advantages of Using a Wet Jet Cutter

Employing a wet jet cutter brings numerous benefits that set it apart from other cutting technologies. One of the primary advantages is its cold-cutting capability, which prevents heat-related issues like warping, melting, or changes in material properties. This is especially valuable for metals that are prone to hardening or for composites that may delaminate under thermal stress. Additionally, the wet jet cutter is highly versatile, capable of handling a diverse array of materials—from soft plastics to tough alloys—without the need for tool changes. This flexibility reduces downtime and increases productivity in multi-material projects. Another significant benefit is the environmental friendliness of the wet jet cutter; it uses water and natural abrasives, producing minimal hazardous waste compared to methods involving chemicals or gases. The precision of a wet jet cutter is also noteworthy, as it can achieve intricate cuts with smooth edges, reducing the need for secondary finishing processes. Moreover, the absence of heat means no harmful fumes are generated, enhancing workplace safety. From a cost perspective, while initial investment might be higher, the wet jet cutter offers long-term savings through reduced material waste, lower energy consumption, and minimal maintenance requirements when properly cared for.

Common Applications of Wet Jet Cutters

The wet jet cutter finds applications across a broad spectrum of industries due to its adaptability and precision. In the aerospace sector, it is used to cut lightweight composites and titanium components with exacting tolerances, ensuring structural integrity without compromising material strength. The automotive industry relies on wet jet cutters for shaping body panels, gaskets, and interior parts, where clean edges and no heat damage are crucial. In architecture and construction, wet jet cutters are employed to slice through stone, tiles, and glass for custom designs, such as intricate mosaics or countertops, offering artistic freedom without chipping or cracking. The food industry utilizes pure water jet cutting (without abrasives) for portioning products like meat, pastries, and frozen goods, maintaining hygiene and preventing contamination. Additionally, in the medical field, wet jet cutters are instrumental in fabricating precision instruments and implants from biocompatible materials, where sterility and accuracy are non-negotiable. Even in artistic and signage applications, the wet jet cutter enables the creation of detailed patterns in wood, acrylic, or metal, supporting customization and small-batch production. This widespread use underscores the wet jet cutter’s role as a multi-functional tool that adapts to evolving industry demands.

Different Types of Wet Jet Cutters

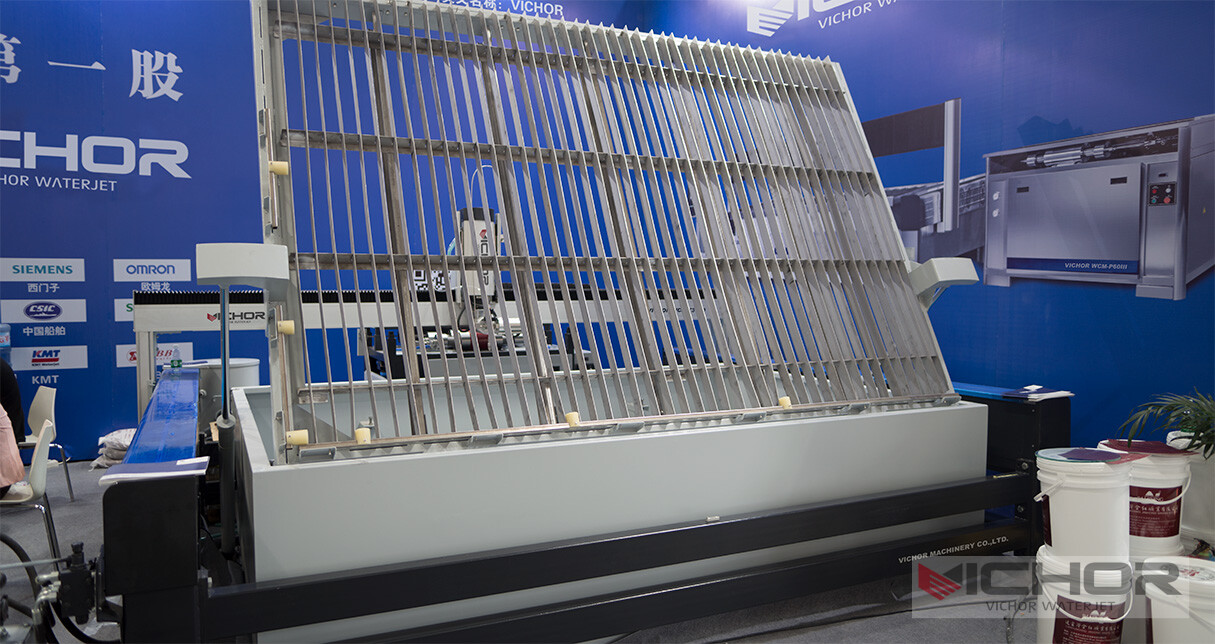

Wet jet cutters can be categorized based on their cutting mechanisms and configurations, each suited to specific tasks. The two main types are pure water jet cutters and abrasive water jet cutters. Pure water jet cutters use only high-pressure water and are ideal for softer materials like rubber, foam, food products, or thin plastics. They offer the advantage of being clean and simple, with lower operating costs since no abrasives are involved. In contrast, abrasive water jet cutters incorporate garnet or other hard particles into the water stream, enabling them to cut through hard materials such as steel, ceramics, stone, and thick composites. This type is more common in industrial settings due to its enhanced cutting power. Beyond this, wet jet cutters can be classified by their motion systems: gantry-style cutters are used for large-scale projects like shipbuilding or architectural stone cutting, providing a wide work envelope, while robotic arm systems offer greater flexibility for 3D cutting in complex geometries. Some advanced models feature multi-head setups, allowing simultaneous cutting of multiple pieces to boost efficiency. Understanding these variations helps in selecting the right wet jet cutter for specific applications, ensuring optimal performance and cost-effectiveness.

Maintenance and Safety Tips for Wet Jet Cutters

Proper maintenance of a wet jet cutter is essential to ensure longevity, reliability, and safety. Regular checks should include inspecting the high-pressure pump for leaks or pressure drops, as these can indicate wear in seals or valves. The nozzle and orifice require frequent examination for erosion or clogging; replacing them periodically prevents loss of cutting accuracy. Filters in the water supply system must be cleaned or replaced to avoid contaminants that could damage the pump or abrasive delivery system. For abrasive wet jet cutters, it’s important to monitor the abrasive hopper and delivery lines for blockages and to use high-quality abrasives to maintain consistent cutting performance. Safety measures are equally critical: operators should wear protective gear, such as safety glasses and ear protection, due to the high noise levels and potential for flying debris. The work area must be kept dry to prevent slips, and emergency stop buttons should be accessible. Additionally, implementing routine software updates for the CNC controls can enhance precision and prevent errors. By adhering to these maintenance and safety protocols, users can minimize downtime and extend the life of their wet jet cutter, while ensuring a secure working environment.

Future Trends in Wet Jet Cutting Technology

The evolution of wet jet cutter technology is driven by demands for higher efficiency, smarter automation, and sustainability. One emerging trend is the integration of IoT (Internet of Things) and AI (Artificial Intelligence) for predictive maintenance and real-time monitoring. Sensors can track parameters like pressure, flow rate, and nozzle wear, alerting operators to potential issues before they cause downtime. Another development is the enhancement of energy efficiency, with newer models featuring regenerative drives and optimized pump designs that reduce power consumption. Eco-friendly innovations are also gaining traction, such as water recycling systems that minimize usage and abrasive recovery methods that cut waste. In terms of performance, advancements in nozzle materials and design are enabling faster cutting speeds and improved accuracy, expanding the capabilities of the wet jet cutter in micro-machining and high-volume production. Furthermore, the adoption of hybrid systems that combine wet jet cutting with other technologies, like lasers for marking or drilling, is on the rise, offering integrated solutions for complex manufacturing processes. These trends indicate a future where the wet jet cutter becomes even more accessible, efficient, and integral to smart factories and sustainable practices.

In summary, the wet jet cutter is a transformative tool that combines precision, versatility, and environmental benefits to meet diverse industrial needs. By understanding its workings, advantages, applications, types, and maintenance requirements, users can leverage this technology to achieve superior cutting results. As innovations continue to emerge, the wet jet cutter is poised to play an even greater role in advancing manufacturing and fabrication processes.

Frequently Asked Questions

Q1: What materials can a wet jet cutter effectively cut?

A1: A wet jet cutter can handle a wide range of materials, including metals like steel and aluminum, composites, stone, glass, ceramics, plastics, rubber, and even food items. The key advantage is its ability to cut without heat, making it suitable for heat-sensitive or brittle materials that might be damaged by other methods.

Q2: How does the precision of a wet jet cutter compare to laser cutting?

A2: While both methods offer high precision, a wet jet cutter typically provides similar or better accuracy for thick materials and does not produce heat-affected zones. It can achieve tolerances as tight as 0.1 mm, but laser cutting might be faster for thin metals. The wet jet cutter excels in versatility across different material types without thermal distortion.

Q3: Is operating a wet jet cutter expensive in terms of consumables?

A3: The operating costs for a wet jet cutter include water, electricity, and abrasives (if used). While abrasives like garnet can add to expenses, the overall cost is often offset by reduced waste and no need for secondary finishing. Pure water jet cutting for soft materials is generally more economical, as it avoids abrasive costs.

Q4: What safety precautions are necessary when using a wet jet cutter?

A4: Essential safety measures include wearing protective equipment such as goggles, gloves, and hearing protection due to high noise levels. Ensure the workspace is well-ventilated and dry to prevent accidents. Regular training on emergency procedures and machine operation is crucial, along with routine inspections to maintain system integrity.

Q5: Can a wet jet cutter be used for 3D cutting applications?

A5: Yes, with advanced CNC controls and robotic arm systems, a wet jet cutter can perform 3D cutting on complex shapes and contours. This is particularly useful in industries like aerospace and automotive for manufacturing components with intricate geometries, providing flexibility beyond flat sheet cutting.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read