Waterjet Cutting Speed Explained: What You Need to Know

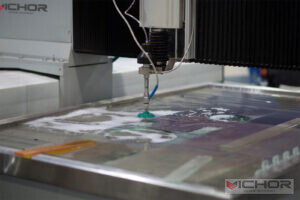

Waterjet cutting has revolutionized manufacturing and fabrication, offering a versatile and precise method for slicing through a vast array of materials. At the heart of this technology’s efficiency and cost-effectiveness is one critical factor: waterjet cutting speed. Understanding what influences this speed, how it interacts with other process variables, and how to optimize it is crucial for any shop looking to maximize productivity. This article delves into the intricacies of waterjet cutting speed, exploring the factors that dictate it, the trade-offs involved, and solutions to common problems.

What Exactly Determines Waterjet Cutting Speed?

The rate at which a waterjet head moves across a material—the waterjet cutting speed—is not a arbitrary setting. It is a carefully calculated value derived from a complex interplay of several mechanical and material factors. Pushing the speed too high can lead to poor cut quality and incomplete penetration, while going too slow wastes time and abrasives, increasing operating costs.

Key determinants include:

Material Type and Thickness: This is the most obvious factor. Softer materials like rubber, foam, or food products can be cut at very high speeds using pure waterjets (without abrasive). Harder materials like titanium, tool steel, or granite require an abrasive garnet mixed into the stream and must be cut much more slowly. Furthermore, doubling the material thickness does not simply halve the speed; the relationship is exponential, requiring a significant reduction in waterjet cutting speed for thicker slabs.

Water Pressure: Modern ultra-high pressure pumps operate at intensities of 60,000 PSI (4,100 bar) or even 90,000 PSI (6,200 bar). Higher pressure creates a more powerful and focused stream, allowing for faster cutting speeds through tough materials. However, this comes with increased energy consumption and wear on system components.

Abrasive Flow Rate and Quality: The garnet abrasive does the majority of the cutting in hard materials. A consistent and optimal flow rate is essential. Too little abrasive results in slow, weak cutting, while too much can clog the mixing tube and disrupt the stream. The size and hardness of the abrasive grit also play a role; larger, sharper garnet typically allows for a higher waterjet cutting speed.

Nozzle and Orifice Condition: The orifice (a gemstone like diamond or sapphire) creates the fine water jet, and the mixing tube (also called the focus tube) mixes water and abrasive. Both are consumable parts. As they wear, the stream becomes less coherent and powerful, reducing the maximum effective cutting speed. Regular inspection and replacement are necessary to maintain peak performance.

Desired Cut Quality: This is a crucial trade-off. A faster cut often results in a slightly tapered edge (wider at the top than the bottom) and more striation lines (subtle ridges). For many industrial parts, this is acceptable. However, if a project requires a perfectly smooth, precise edge with minimal taper, the waterjet cutting speed must be significantly reduced to allow the stream to dwell longer on the material.

How Material Choice Drastically Alters Cutting Velocity

The impact of material on speed cannot be overstated. To illustrate the vast range, consider these approximate speed comparisons for a standard thickness (e.g., 1 inch/25mm) using an abrasive waterjet:

Soft Materials (Pure Waterjet): Foam, rubber, and thin plastics can be cut at remarkable speeds exceeding 500 inches per minute (ipm) or ~13 meters per minute.

Aluminum: A common material for waterjets, 1-inch thick aluminum might be cut at around 7-10 ipm (0.18 – 0.25 m/min) for a high-quality finish.

Stainless Steel: Being harder and denser, the waterjet cutting speed for 1-inch stainless steel would be slower, perhaps in the range of 4-6 ipm (0.10 – 0.15 m/min).

Titanium: Even slower still, often around 3-5 ipm (0.08 – 0.13 m/min) for the same thickness.

Hardened Tool Steel and Ceramics: These are among the slowest, with speeds potentially dropping to 2-4 ipm (0.05 – 0.10 m/min) to achieve a clean cut.

These examples highlight why the material is the primary starting point for any calculation of waterjet cutting speed.

The Critical Balance Between Speed and Cut Quality

A operator cannot simply select the maximum possible waterjet cutting speed for a given material. They must balance speed with the quality requirements of the final part. This balance manifests in a few key ways:

Striations: These are wave-like patterns on the cut edge. Faster cutting speeds create deeper, more pronounced striations. Slower speeds produce a smoother, near-polished finish. Modern dynamic waterjet heads can automatically adjust the speed and/or head tilt to compensate for natural taper and striation, maintaining high speed and quality.

Taper: All waterjet cuts have a slight V-shape (kerf taper). The faster the cut, the more pronounced this taper becomes. For precision parts that must fit together perfectly, a slower speed or specialized tilting head technology is used to produce a near-vertical edge.

Edge Squareness: Related to taper, the goal is often a perfectly square edge. Speed, nozzle height, and abrasive quality all influence the squareness of the cut. Finding the optimal waterjet cutting speed is essential for achieving this.

The Direct Impact of Cutting Speed on Operational Costs

The waterjet cutting speed is directly tied to the profitability of a job. A faster cut means more parts produced per hour, lowering the cost per part. However, this must be balanced against other cost factors:

Abrasive Consumption: Cutting at a faster speed may use abrasive more efficiently in terms of time, but the consumption rate (lbs/min) remains fairly constant. The major savings is in time and labor.

Power Consumption: The high-pressure pump is the largest consumer of electricity. Reducing cut time by increasing speed directly reduces energy costs for that part.

Labor and Overhead: Faster throughput means a machine is idle less often, maximizing its return on investment and spreading fixed costs (like rent and labor) across a larger number of finished parts.

Therefore, optimizing the waterjet cutting speed isn’t just a technical goal—it’s a fundamental business imperative.

Techniques and Tech to Optimize Your Waterjet’s Speed

You don’t have to simply accept the baseline speed for a material. Several methods and technologies can help you push the limits safely and effectively:

Regular Maintenance: This is the simplest and most often overlooked factor. Replacing worn orifices and mixing tubes before they are completely shot ensures the stream is always at its most powerful, maintaining optimal waterjet cutting speed.

High-Quality Abrasive: Using a consistently sized, hard, sharp garnet abrasive ensures efficient cutting. Cheap, inconsistent, or damp abrasive can clump and flow poorly, drastically reducing cutting efficiency and speed.

Advanced Software: Modern nesting software does more than just arrange parts on a sheet. It can calculate the optimal waterjet cutting speed for different materials and thicknesses, manage pierce points, and implement strategies for reducing taper.

Dynamic Head Technology: This is a game-changer. Heads that can automatically tilt slightly into the direction of travel (called 5-axis cutting) can virtually eliminate taper and allow for faster cutting speeds while still maintaining high quality on both the top and bottom edges of the cut.

Common Waterjet Cutting Speed Problems and Their Solutions

Even well-tuned systems encounter issues. Here are common problems related to speed and how to fix them.

Problem: Incomplete Cutting or “Washing Out” at the Bottom.

Cause: The waterjet cutting speed is too high for the material thickness. The stream doesn’t have enough time to fully penetrate and exit the material cleanly.

Solution: Reduce the feed rate. Check and calibrate the pump pressure to ensure it’s at the specified level.

Problem: Excessive Striations or a Rough Finish.

Cause: The speed is either too high or, in some cases, too low. It can also be caused by a worn mixing tube or incorrect abrasive flow.

Solution: Adjust the speed slower for a better finish. Check and replace the mixing tube if it’s worn. Verify the abrasive flow rate is set correctly according to the nozzle size.

Problem: The Jet “Lags” or Curves in Corners.

Cause: The programmed waterjet cutting speed is too high for the machine’s acceleration capabilities. The cutting head cannot change direction fast enough, causing a rounded corner instead of a sharp one.

Solution: Reduce the overall cutting speed for the entire path or use software features that automatically slow the head before a corner to ensure precision.

Problem: Taper is Worse Than Usual.

Cause: Nozzle standoff height is incorrect, the mixing tube is worn, or the speed is too high.

Solution: Ensure the nozzle is at the correct height from the material (usually ~0.060″-0.125″). Replace the worn mixing tube. Consider reducing speed or investing in a dynamic head to combat taper.

Problem: Abrasive Feed is Inconsistent, Causing Variable Cutting.

Cause: Moisture in the abrasive line, a clogged feeder, or using the wrong size abrasive for the nozzle.

Solution: Ensure abrasive is stored in a dry environment. Clean the abrasive feeder and delivery system regularly. Confirm the abrasive mesh size is compatible with your orifice and mixing tube specifications.

Ultimately, mastering waterjet cutting speed is about understanding the delicate dance between power, material, time, and quality. By focusing on the factors within your control—maintenance, abrasive quality, and software settings—you can harness the full potential of your waterjet system, pushing its speed to the limits without sacrificing the precision that makes this technology so valuable.

continue reading

Related Posts

- 1281 words6.5 min read