Waterjet Cutting Cost: A Practical Breakdown for Your Project Budget

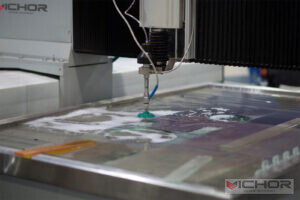

If you’re sourcing parts for a prototype, a machine build, or an art installation, you’ve likely considered waterjet cutting. The promise of precise, cold-cut parts from almost any material is powerful. But then the big question hits: what’s the actual waterjet cutting cost?

Many shops are hesitant to ask for a quote because the pricing seems opaque. Is it by the hour? By the inch? This article will demystify the numbers. We’ll break down the real factors that determine your final bill and show you how to manage your waterjet cutting cost effectively. You’ll learn how companies like VICHOR structure their pricing to provide clarity and value.

The Core Components of Waterjet Cutting Cost

Understanding waterjet cutting cost starts with knowing what you’re paying for. It’s rarely a single, simple number. Instead, it’s a combination of several operational factors.

The most significant variable is machine time. This is often called the “cutting time” or “table time.” The longer the machine runs to produce your part, the higher the cost. This time is influenced by the material’s thickness and hardness.

Abrasive consumption is another major factor. For cutting metals, stone, and composites, a hard garnet sand is used. This abrasive is a consumable, and its cost is directly factored into the job. Thicker, harder materials use more abrasive per minute.

Overhead and operational expenses are also included. This covers electricity for the high-pressure pump, water filtration, routine maintenance, and wear parts like nozzles and seals.

Material Type and Thickness: The Primary Drivers

The relationship between your material and the final waterjet cutting cost is direct. Cutting soft materials like foam or rubber with a pure waterjet is very fast and cheap. Switching to aluminum or steel slows the process down significantly.

Material thickness is even more critical. Doubling the thickness of a metal plate does not double the cost; it can often more than triple it. The machine must slow its cutting speed dramatically to ensure a clean cut through the entire depth.

Exotic materials like titanium or hardened tool steel also command a higher waterjet cutting cost. They are harder on the consumables and require even slower cutting speeds to maintain edge quality.

Understanding Pricing Models: Per Hour vs. Per Part

Most job shops use two main pricing models. The first is an hourly rate. You pay for the time the machine spends cutting your parts. This is common for prototyping, R&D, and complex one-off projects.

The second model is a per-part price. This is standard for production runs. The shop calculates the total machine time, material, and setup to give you a fixed price per unit. This benefits you for larger quantities through economies of scale.

Some providers may also charge a one-time programming or setup fee. This covers the time to prepare your CAD file and set up the machine. At VICHOR, we often waive this fee for repeat customers or substantial orders.

How Complexity and Tolerances Impact Your Quote

A simple square is cheap. A complex gear with fine teeth is more expensive. This is a fundamental rule of waterjet cutting cost.

Intricate designs with sharp corners and tight radii require the machine to slow down. This increases the total cutting time. Every start and stop, every direction change, adds seconds that accumulate into minutes and hours on large jobs.

Tighter tolerances also increase cost. Holding a cut within ±0.005″ requires more careful programming and slower speeds than a ±0.030″ tolerance. If your design has many small, precise holes, expect this to be reflected in the quote.

Comparing Waterjet Cutting Cost to Laser and Plasma

It’s helpful to view waterjet cutting cost in context. For thin sheet metal, laser cutting is often faster and cheaper. However, laser creates a heat-affected zone (HAZ) that can warp the material or alter its properties.

Plasma is the low-cost leader for thick, mild steel plates where precision and edge quality are not critical. But plasma has a very wide kerf and a large HAZ.

The value of a waterjet isn’t always in being the cheapest. Its value is in being the most capable. You pay for the cold-cut process, material versatility, and high precision. There are no secondary costs for heat treatment or warping correction.

Practical Tips to Reduce Your Waterjet Cutting Cost

You have more control over the final price than you might think. The single most effective way to lower your waterjet cutting cost is through efficient nesting.

By arranging your parts tightly on the material sheet, you minimize waste. You also reduce the total cutting distance the machine must travel. Good CAD software can help with this, and experienced shops like VICHOR will always optimize nesting for their clients.

Consider your tolerances. Do you really need that ±0.005″ tolerance, or will ±0.015″ work? Specifying unnecessarily tight tolerances can inflate your waterjet cutting cost without providing a functional benefit.

Choosing the right material thickness is also key. If you’re having a part cut from 1-inch plate but only need a 0.75-inch profile, you are paying a premium for that extra, uncut material.

VICHOR’s Approach to Transparent and Competitive Pricing

At VICHOR, we believe a clear quote is the foundation of a good partnership. We break down our waterjet cutting cost estimates to show you where your money is going.

Our global service centers are equipped with modern, efficient machines. This allows us to maintain competitive hourly rates and per-part prices. We invest in technology that reduces abrasive consumption and energy use, savings we pass on to our customers.

We also offer value-added services that can ultimately lower your total project cost. This includes in-house design assistance to optimize your files for cutting and secondary operations like deburring and drilling.

For high-volume projects, we develop dedicated production solutions that maximize throughput and minimize the unit waterjet cutting cost.

The Hidden Costs of Choosing the Cheapest Provider

A low quote can be tempting, but it’s essential to look deeper. A surprisingly low waterjet cutting cost might indicate inexperience or corner-cutting.

Inexpensive shops may use lower-quality abrasive, which can lead to poor edge quality and taper. They might run their machines too fast to save time, resulting in inconsistent cuts and failed parts.

The real cost of a botched job isn’t just the money lost on the parts. It’s the project delay, the wasted material, and the scramble to find a new supplier.

Partnering with an established provider like VICHOR ensures reliability. You pay a fair market price for a guaranteed result, on-time delivery, and professional support.

Getting an Accurate Quote for Your Project

The best way to understand your waterjet cutting cost is to get a formal quote. To get an accurate estimate, be prepared to provide specific information.

You will need to specify the material type and exact thickness. A CAD file (DXF or DWG) of the part is essential. You should also communicate your required quantities, tolerances, and any post-processing needs.

Don’t hesitate to ask questions. A good supplier will explain their pricing and help you find ways to make your project more cost-effective. At VICHOR, our project engineers are ready to review your files and provide a detailed, no-obligation quote quickly.

Frequently Asked Questions

Q1: What is a typical hourly rate for waterjet cutting services?

A1: Hourly rates vary by region and machine capability, but generally fall between $75 and $150 per hour. High-production machines with advanced features may be at the upper end, while smaller shops may charge less.

Q2: Does waterjet cutting cost more for hardened steels?

A2: Yes. Harder materials like AR400 or tool steel require slower cutting speeds and consume more abrasive, which increases the overall waterjet cutting cost compared to mild steel or aluminum.

Q3: Is there a minimum charge for a waterjet cutting job?

A3: Most shops have a minimum order charge, typically ranging from $50 to $150. This covers the fixed costs of setup and programming, making small jobs economically viable for the supplier.

Q4: How does part quantity affect the price per unit?

A4: As quantity increases, the price per unit drops significantly. The setup cost is amortized over more parts, and nesting efficiency often improves. The machine can also run at optimal speed for longer periods.

Q5: Can I supply my own material to reduce costs?

A5: Often, yes. Many shops allow client-supplied material. This can lower your total bill, but be aware that the shop will typically still charge a fee for handling and programming the material you provide.

continue reading

Related Posts

- 1315 words6.6 min read

- 1300 words6.6 min read

- 1232 words6.2 min read