Waterjet Cutting Stone

Precision Systems for Every Application

waterjet cutting stone. By harnessing the power of high-pressure water and abrasive materials, our systems deliver unparalleled precision and versatility, eliminating the heat-affected zones that plague traditional cutting methods. At VICHOR, we specialize in providing innovative and efficient precision stone cutting solutions tailored for small and medium-sized businesses, empowering you to achieve flawless results and drive growth.

Key Takeaways

- Universal Material Compatibility: Cuts any stone type, including granite, marble, and engineered stone, with no heat damage or cracking.

- Exceptional Precision: Achieves intricate designs and tight tolerances for complex projects.

- Impressive Thickness Capacity: Handles material thickness up to 12 inches (30 cm), depending on density.

- Eco-Friendly Operation: An environmentally friendly process that produces no toxic fumes or dust.

- Cost-Effective: Reduces material waste and minimizes the need for costly and time-consuming secondary finishing.

abrasive waterjet stone cutting become clear, especially when compared to traditional methods like diamond wire saws and CNC routers. While each method has its place, VICHOR’s waterjet cutting stone

| Feature | VICHOR Waterjet | Diamond Wire Saw | CNC Router |

|---|---|---|---|

| Precision | Excellent (±0.1mm) | Good | Good |

| Heat Impact | None | Moderate | High |

| Material Waste | Minimal (0.5-1mm kerf) | Moderate | High |

| Complex Shapes | Excellent | Limited | Good |

| Edge Quality | Superior | Good | Fair |

What Are the Key Benefits of Waterjet Stone Cutting?

waterjet stone cutting machine from VICHOR provides a multitude of benefits that directly impact your bottom line and production quality. The remarkably smooth edges produced by our waterjets require little to no secondary finishing, saving valuable time and labor costs. By minimizing material waste through a narrow kerf, our precision systems ensure you get the most out of every slab. In fact, according to research on waterjet cutting efficiency, the technology can reduce material waste by up to 30% compared to traditional methods. Furthermore, the environmental benefits of waterjet stone cutting are significant; the process produces no toxic fumes or dust, creating a safer work environment. The ability to create waterjet cutting stone intricate designs

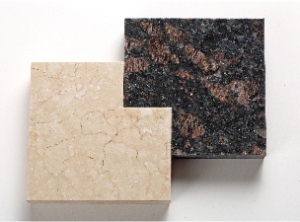

What Types of Stone Can VICHOR Waterjet Cut?

Granite

Known for its hardness and durability, granite is a popular choice for countertops and high-traffic surfaces. Our systems perform waterjet cut granite with ease, creating smooth edges and complex shapes that are difficult to achieve with conventional tools.

Marble

The delicate and often brittle nature of marble makes it a challenge for traditional cutting methods. Waterjet marble cutting eliminates the risk of breakage, preserving the stone’s natural beauty while executing intricate designs flawlessly.

Slate

This fine-grained metamorphic rock can be effortlessly cut into unique shapes for roofing, flooring, and decorative items, all while maintaining its structural integrity.

Limestone

Ideal for projects requiring detailed cuts for architectural elements and decorative pieces, our waterjets cut limestone with the high precision needed for perfect-fit installations.

Soapstone

Valued for its heat resistance, soapstone can be precisely cut for countertops, sinks, and masonry heaters, with our waterjets providing a perfect finish every time.

Travertine

Whether for floor tiles or decorative wall panels, our waterjet systems ensure smooth, precise cuts in travertine, enhancing its natural, fibrous appearance without causing chipping or cracking.

Engineered Stone

Composite materials like quartz and other engineered stones are cleanly and accurately cut, making our waterjets the ideal tool for modern kitchen countertops and custom applications.

Porcelain and Ceramic Tile

From complex inlays to custom medallions, our waterjets cut through porcelain and ceramic tiles at high speed without causing breakage, enabling highly detailed and artistic designs.

What Industries Benefit Most from Waterjet Cutting Stone?

The precision and versatility of waterjet cutting stone make it an indispensable tool across a wide range of industries. Fabricators and designers rely on this technology to push creative boundaries and deliver high-quality products.

The precision and versatility of waterjet cutting stone make it an indispensable tool across a wide range of industries. Fabricators and designers rely on this technology to push creative boundaries and deliver high-quality products.

Countertop Fabrication

In the competitive countertop market, the ability to perform waterjet cut granite countertops with complex edge profiles, sink cutouts, and faucet holes provides a significant advantage. The precision of waterjet cutting ensures a perfect fit and finish, reducing installation time and material waste.

Architectural Elements

Architects and designers use waterjet technology to create custom stone elements, including decorative panels, columns, and facades. The ability to execute intricate designs allows for unique and sophisticated architectural features.

Monument and Memorial Work

The creation of detailed lettering, inlays, and shapes in granite and marble for monuments and memorials is a perfect application for precision stone cutting with a waterjet.

Flooring and Tile

Waterjet cutting is used to create custom floor medallions, borders, and intricate tile patterns that would be nearly impossible to produce with traditional saws.

Artistic and Decorative Work

Artists and craftsmen use waterjets to cut stone for sculptures, signage, and other decorative pieces, leveraging the technology’s ability to reproduce complex digital designs in stone.

These examples only scratch the surface. Explore more cross-industry waterjet applications to see the full potential of this versatile technology.

Which VICHOR Waterjet System is Right for Your Business?

Choosing the best waterjet machine for stone cutting depends on your specific production needs, from the complexity of the designs to the volume of work. VICHOR offers a range of systems to ensure you have the perfect solution for your business.

3-Axis Waterjet Systems

Our 3-Axis systems are the workhorses of the industry, perfect for cutting flat materials with a high degree of precision. They are an excellent choice for businesses focusing on two-dimensional designs in countertops, tiles, and signage.

4-Axis Waterjet Systems

For more complex applications, our 4-Axis systems add the ability to make angled cuts, opening up possibilities for beveled edges and more intricate designs without the need for secondary processing.

5-Axis Waterjet Systems

The ultimate in cutting flexibility, our 5-Axis systems can make complex, multi-axis cuts from any angle. This is the ideal solution for businesses that require extreme precision for advanced architectural components, artistic sculptures, and 3D shapes.

Dual Cutting Head Systems

For businesses needing to increase production output, our dual cutting head systems offer the ability to cut two parts simultaneously, effectively doubling productivity without compromising precision or quality.

Gantry and Cantilever Options

We offer both gantry and cantilever table designs to accommodate different workshop sizes and material handling requirements, ensuring a VICHOR solution can integrate seamlessly into your workflow.

Real Customer Testimonials: Experiences with VICHOR Waterjet Cutting Stone

For our luxury hotel lobby project in Boston, we needed intricate marble inlays with perfect precision. This was the first time I’d worked with VICHOR waterjet, and the results were unbelievable. The 1/8-inch tolerance on complex curves meant zero rework. The materials looked like they were created to fit together naturally. It was such an incredible work!

As a stone sculptor, I need a tool that can bring my digital designs to life with absolute precision. VICHOR waterjet gives me the ability to cut intricate patterns in granite and marble that would be impossible by hand. I recently completed a 12-foot public art installation with over 200 individual pieces, all cut to perfection. I love the flexibility it provides, and I can’t imagine working without it!

Success Stories from Satisfied Customers

Our customers are our best advocates. Many have shared their experiences with VICHOR Waterjet and how it revolutionized their operations. These testimonials reflect our commitment to providing top-notch waterjet cutting solutions that exceed expectations.

How VICHOR Waterjet Helped Businesses Grow and Expand

VICHOR Waterjet isn’t just about cutting stone. It’s about helping businesses grow and expand. By offering a versatile and effective solution, we’ve helped our clients increase their productivity, innovate their offerings, and reach new markets.

Frequently Asked Questions (FAQ) about Waterjet Stone Cutting

What types of stone can be cut with a waterjet?

A VICHOR waterjet can cut virtually any type of stone, thanks to its powerful and precise abrasive cutting stream. This includes hard stones like granite and quartzite, softer stones like marble and limestone, and metamorphic rocks such as slate. We also excel at cutting engineered stone and composite materials like quartz, as well as porcelain and ceramic tiles. This versatility makes a waterjet stone cutting machine an all-in-one solution for stone fabricators, eliminating the need for multiple machines for different materials and allowing for a more flexible and responsive production environment.

How thick can a waterjet cut stone?

The thickness a waterjet can cut depends on the material’s density and the desired cut quality, but our systems are highly capable. VICHOR waterjets can accurately cut stone up to 12 inches (30 cm) thick. For most common applications, such as 3 cm granite countertops or 2 cm marble slabs, the waterjet passes through with ease and at a relatively high speed. The ability to answer the question of how thick can waterjet cut stone with such a high capability showcases the power and industrial strength of our machines.

Is waterjet cutting better than saw cutting for stone?

When comparing waterjet vs saw stone cutting, the waterjet offers several distinct advantages. Unlike saws, waterjets do not generate a heat-affected zone, which prevents micro-fractures and maintains the stone’s structural integrity. Waterjets also provide superior precision for intricate designs and tight corners where a saw blade cannot reach. Furthermore, the waterjet’s narrow kerf minimizes material waste. While a bridge saw may be faster for long, straight cuts, a waterjet is far more versatile, making it the better choice for custom and high-value projects.

Does waterjet cutting damage or crack stone?

No, waterjet cutting stone no heat damage is one of the technology’s most significant benefits. The process is a form of accelerated erosion, using a supersonic stream of water and abrasive particles to cut the material. Because it is a cold-cutting process, it imparts no thermal stress on the stone, eliminating the risk of cracking, discoloration, or warping that can occur with heat-generating methods like lasers or CNC routers. This makes it the safest and most reliable method for cutting valuable or delicate stone materials.

Can waterjet cut intricate designs in stone?

Absolutely. The ability to perform waterjet cutting stone intricate designs is a primary reason why fabricators invest in this technology. Controlled by advanced CNC software, the cutting head can follow complex vector paths with extreme accuracy, reproducing any design from a digital file. This allows for the creation of detailed inlays, custom logos, artistic patterns, and other high-value decorative elements that are impossible to achieve with traditional cutting tools. The precision of the waterjet ensures clean lines and sharp corners, even in the most detailed patterns.

What is the cost of waterjet cutting stone?

The waterjet stone cutting cost is best understood in terms of total value and return on investment rather than a simple hourly rate. While the initial investment in a waterjet machine may be higher than a traditional saw, the operating costs can be lower due to several factors. These include significantly reduced material waste, the elimination of secondary finishing processes, and lower labor costs due to automation. The ability to take on higher-margin custom projects also contributes to a faster ROI. VICHOR’s efficient systems are designed to offer a competitive total cost of ownership.

How accurate is waterjet cutting for stone?

Precision stone cutting is a hallmark of waterjet technology. VICHOR waterjet systems can achieve a positional accuracy of ±0.1mm (0.004 inches), which is exceptionally precise for the stone industry. This high level of accuracy ensures that parts fit together perfectly, inlays are seamless, and final products meet the most demanding client specifications. The accuracy is consistent across different materials and thicknesses, providing reliable and repeatable results that elevate the quality of your finished products and reduce the rate of costly errors or rework.

Conclusion

waterjet cutting stone technology provides a clear competitive advantage. By delivering unparalleled precision, material versatility, and a superior edge finish, our systems empower small and medium-sized businesses to produce higher quality work more efficiently. With the backing of our industry-leading two-year warranty and a focus on tangible business benefits like reduced waste and increased capability, a VICHOR waterjet is not just a machine – it’s a pathway to growth.

See how businesses like yours have achieved remarkable results. Check out more customer success stories in our showcase.