Waterjet Cutting Glass

The Ultimate Guide to Precision Glass Fabrication

waterjet cutting glass

Key Takeaways

- Universal Glass Compatibility: VICHOR waterjet technology cuts virtually any glass type—from delicate optical lenses to 9″ thick bulletproof glass—except tempered or hot glass.

- Zero Heat Damage: The cold cutting process eliminates heat-affected zones, preventing warping, discoloration, and stress fractures that compromise glass integrity.

- Precision Engineering: Proportional pressure control technology (7,200-11,600 PSI) enables crack-free piercing and intricate designs impossible with traditional methods.

- Cost-Effective Versatility: A narrow cutting kerf reduces material waste by up to 40%, while eliminating the need for secondary finishing operations.

- Industry-Leading Warranty: All VICHOR systems are backed by a comprehensive two-year warranty and decades of waterjet cutting innovation and dedicated after-sales support.

What Is Waterjet Cutting for Glass?

cold cutting process creates intricate shapes without generating heat, which eliminates the risk of thermal stress, cracking, or edge damage that can occur with other methods. The technology has its roots in the mid-20th century, but it was the development of abrasive waterjet

How Does Waterjet Technology Cut Glass?

The Abrasive Waterjet Cutting Process

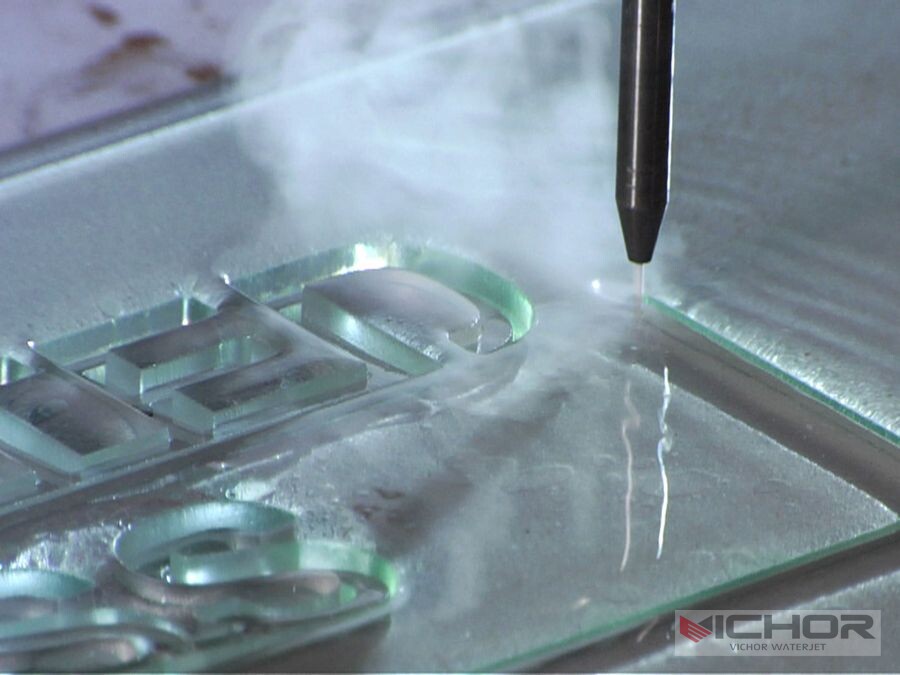

The process begins with an intensifier pump that pressurizes ordinary tap water to extreme levels. This high-pressure water is then piped to the cutting head, where it passes through a tiny orifice, typically made of ruby or diamond, to form a fine, coherent jet. Just after the orifice, the water enters a mixing chamber where a precisely metered amount of abrasive material, such as olivine or garnet, is drawn into the stream. This mixture of water and abrasive then accelerates through a nozzle, or mixing tube, and exits as a supersonic stream capable of cutting through inches of hardened material. The cutting head itself is mounted on a gantry system controlled by CNC (Computer Numerical Control) software, allowing it to follow complex digital design paths with high accuracy.

The Critical Role of Pressure Control

For a brittle material like glass, simply blasting it with a high-pressure jet would cause it to shatter. The key to successful waterjet glass cutting is sophisticated pressure control. VICHOR’s systems utilize proportional pressure control, which begins the process by piercing the glass at a much lower pressure, typically between 7,200 and 11,600 PSI. This gentle start prevents the shock loading that leads to cracking. Once the initial pierce is complete, the system gradually ramps up the pressure to the optimal level for cutting the specific thickness and type of glass. This dynamic pressure management, powered by VICHOR’s advanced intensifier pumps, is what makes it possible to cut even the most delicate glass without damage.

Abrasive Selection: Olivine vs. Quartz Sand

The choice of abrasive is another critical factor in achieving a high-quality finish on glass. While garnet is a common abrasive for general waterjet cutting, olivine

Why Is Waterjet the Best Method for Cutting Glass?

Precision and Smoothness

Waterjet systems can achieve tolerances as tight as ±0.1mm, enabling the creation of highly detailed and accurate parts. The cutting process produces a satin-smooth edge that is free of the chipping and micro-cracks often left by saws or routers. This high-quality finish often eliminates the need for costly and time-consuming secondary operations like grinding or polishing.

Safety for Delicate Materials

The absence of heat is the single greatest advantage of waterjet cutting for glass. Laser cutters can induce thermal shock, and mechanical saws create vibrations and stress, all of which can lead to breakage, especially in delicate or complex pieces. The controlled, low-pressure piercing and cold-cutting nature of waterjet technology make it the safest and most reliable method for fabricating high-value glass components.

Versatility Across Applications

A single waterjet machine can cut a vast range of glass types and thicknesses, from thin 1mm optical lenses to 9-inch thick laminated security glass. The same machine can produce intricate artistic designs for a stained-glass window and then switch to cutting robust panels for an architectural facade. This flexibility makes it an invaluable asset for job shops and custom fabricators.

Cost-Effectiveness

What Types of Glass Can Be Cut with Waterjet?

VICHOR waterjet technology is engineered to handle virtually every type of glass used in modern architectural, industrial, and artistic applications. Its versatility is one of its most significant advantages over other cutting methods.

VICHOR waterjet technology is engineered to handle virtually every type of glass used in modern architectural, industrial, and artistic applications. Its versatility is one of its most significant advantages over other cutting methods.

Flat Glass: The Standard for Most Applications

This is the most common type of glass, used for windows, panels, and tabletops. Waterjet can cut flat glass of any thickness with exceptional precision, creating clean edges for seamless integration into building facades or furniture.

Laminated Glass: Multi-Layer Precision

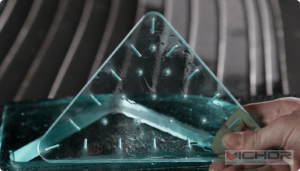

Laminated glass, used in car windshields and safety windows, consists of multiple layers of glass bonded with a polymer interlayer. Cutting this material is challenging as it can cause delamination. VICHOR’s controlled pressure technology cuts through all layers cleanly in a single pass without compromising the bond.

Bulletproof Glass: Cutting Dense Security Materials

Composed of multiple layers of glass and polycarbonate, bulletproof or ballistic glass can be up to 9 inches thick. Waterjet is one of the few technologies capable of cutting this dense material with the precision required for armored vehicles and secure facilities, all without affecting its structural integrity.

Optical Glass and Lenses: Extreme Precision Required

In the electronics and medical industries, components like optical lenses and display screens demand extreme precision. Waterjet technology can cut these sensitive materials to tight tolerances without introducing any stress or defects that could impair their optical properties.

Mirrors: Delicate Reflective Surfaces

Cutting mirrors presents the challenge of not damaging the delicate reflective coating on the back. The low-pressure start and controlled cutting of a waterjet system ensure the coating remains intact, delivering a perfect cut without chipping or flaking.

Specialty Glass Types

VICHOR waterjets are also perfectly suited for a range of specialty glasses, including heat-resistant borosilicate glass, high-purity quartz glass, decorative **crystal glass**, and colorful **stained glass** for artistic applications.

⚠️ Limitations: What Glass Cannot Be Cut

It is crucial to understand that tempered glass cannot be cut by a waterjet or any other method. The tempering process creates high internal stress, and any attempt to cut it will cause the entire sheet to shatter into small, granular pieces. All cutting and shaping must be done before the glass is tempered. Similarly, hot glass is not suitable for waterjet cutting due to the risk of thermal shock.

What Are the Key Advantages of VICHOR Waterjet Glass Cutting?

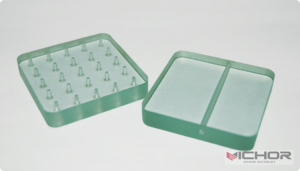

Unparalleled Geometric Capabilities

Waterjet cutting liberates designers from the constraints of traditional tools. It can produce curves, sharp corners, and intricate internal cutouts that are impossible with scoring or sawing. This capability allows for the creation of everything from complex artistic inlays for church mosaics to precision components for industrial machinery.

Zero Cracking During Processing

Our proprietary proportional pressure control technology is the key to our greater than 99% crack-free piercing success rate. By starting at a low, gentle pressure and smoothly ramping up, our systems avoid the thermal and mechanical shock that causes fractures, ensuring your valuable material is not wasted.

Versatility Across Thickness Ranges

A single VICHOR waterjet machine can handle the full spectrum of glass thicknesses without requiring tooling changes. It can delicately cut a 1mm-thin sheet for an electronic display and then, with a simple software adjustment, power through a 9-inch block of security glass. This versatility maximizes productivity and ROI.

No Heat-Affected Zone (HAZ)

Unlike laser cutting, which melts the material and can create a heat-affected zone (HAZ) along the cut edge, waterjet is a completely cold process. This means the glass right up to the edge of the cut retains its original strength, clarity, and structural integrity, with no risk of discoloration or warping.

Minimal Material Waste

The waterjet stream has a very narrow kerf, or cutting width, typically between 0.5mm and 1.5mm. This allows parts to be nested tightly together on a sheet of glass, minimizing scrap. This can lead to material cost savings of up to 40% compared to methods with wider cutting paths, a significant advantage when working with expensive materials.

Intricate Design Capabilities

Our systems integrate seamlessly with CAD/CAM software, allowing you to import digital designs directly to the machine. With optional 5-axis cutting heads, you can even create beveled edges, countersunk holes, and complex 3D shapes, opening up a new world of design possibilities.

VICHOR’s Unique Edge: Technology + Support

How Does Waterjet Compare to Other Glass Cutting Methods?

Choosing the right cutting method is critical for achieving the desired quality, efficiency, and cost-effectiveness. Here’s how waterjet technology stacks up against other common methods for cutting glass.

| Feature | Waterjet | Laser Cutting | Traditional Scoring | CNC Router |

|---|---|---|---|---|

| Heat Generation | None | High | None | Moderate |

| Thickness Capacity | Up to 9″ | Up to 1″ | Up to 0.5″ | Up to 2″ |

| Edge Quality | Smooth, polished | May have HAZ | Sharp, requires finishing | Rough edges |

| Precision | ±0.1mm | ±0.05mm | ±0.5mm | ±0.2mm |

| Complex Shapes | Excellent | Good | Limited | Good |

| Material Waste | Minimal | Low | Moderate | High |

| Operating Cost | Moderate | High | Low | Moderate |

Laser cutting is fast and highly precise on thin glass, but its use of heat is a major drawback. The thermal stress can cause cracking and creates a heat-affected zone that may require secondary polishing. Lasers are also limited to a maximum thickness of about 1 inch. Waterjet, being a cold process, has none of these limitations and is far superior for thick or heat-sensitive glass.

Waterjet vs. Traditional Scoring

Manual scoring and breaking is the oldest method, but it is limited to simple, straight cuts on thin glass. It lacks precision and cannot create internal cutouts or complex curves. The edges are sharp and always require extensive grinding and polishing. Waterjet is vastly superior in every aspect of quality, precision, and design freedom.

When Waterjet Is the Clear Winner

What Are the Real-World Applications of Waterjet Glass Cutting?

VICHOR waterjet technology is a driving force in a diverse range of industries, enabling innovation and quality in countless applications where precision glass is essential.

Architectural and Construction Applications

In modern architecture, glass is a central element. Waterjet cutting is used to create custom-sized panels for building facades and curtain walls, frameless shower screens with precise hinge cutouts, decorative kitchen splashbacks, and elegant glass railings and balustrades.

Artistic and Decorative Applications

Artists and designers use waterjet to realize their most ambitious visions. This includes cutting intricate pieces for stained-glass windows, creating detailed inlays for tabletops and floors, sculpting glass art installations, and fabricating custom light fixtures and ornamental pieces.

Industrial and Manufacturing Applications

From automotive to electronics, waterjet plays a key role. It is used to cut car windshields and sunroofs, aircraft canopies, and the ultra-strong glass for smartphone screens and display panels. In the medical field, it is used to produce components for laboratory equipment and diagnostic devices with high precision.

Specialty and Custom Projects

Waterjet technology excels at unique, one-off projects. This includes cutting multi-layered bulletproof glass for security vehicles, fabricating replacement windows for antique cars, shaping custom mirrors for interior design, and producing insulated glass panels for energy-efficient buildings.

VICHOR Waterjet Glass Cutting: Technical Specifications

Understanding the technical capabilities of our systems is key to appreciating the VICHOR advantage. We engineer our machines to outperform industry standards and deliver superior results.

| Specification | VICHOR Capability | Industry Standard |

|---|---|---|

| Pressure Range | 7,200 – 87,000 PSI | 30,000 – 60,000 PSI |

| Glass Piercing Pressure | 7,200 – 11,600 PSI | Variable |

| Maximum Thickness | 9″ (23 cm) | 2-4″ typical |

| Cutting Tolerance | ±0.1 mm | ±0.2-0.5 mm |

| Kerf Width | 0.5 – 1.5 mm | 1-3 mm |

| Edge Quality | Polished finish | Varies |

| Abrasive Type | Olivine or Garnet (80-120 mesh) | Garnet typical |

- Proportional Pressure Control: Prevents cracking by starting at a low pressure and ramping up smoothly.

-

5-Axis Cutting Capability: Allows for the creation of complex 3D shapes and beveled edges.

-

CAD/CAM Integration: Enables direct import of your digital design files for seamless operation.

-

Automatic Abrasive Feed

How to Achieve Optimal Results When Cutting Glass with Waterjet

Proper Fixturing and Support

Always place the glass sheet on a dedicated support material, such as a waterjet brick. This soft backing absorbs the energy of the waterjet stream after it passes through the glass, preventing it from reflecting and causing damage to the bottom surface. Ensure the glass is evenly supported to prevent vibration.

Abrasive Selection and Quality

Use a fine mesh abrasive (80-120 mesh) for glass to achieve a smooth edge. Olivine is recommended for a more polished finish, while garnet can be used for faster cutting speeds. Always use a high-quality abrasive with consistent particle size to ensure a uniform cut.

Pressure Management

Leverage your system’s pressure control capabilities. Always use a low-pressure pierce (7,200-11,600 PSI) to start the cut. The pressure should then be ramped up gradually to the appropriate level for the material’s thickness. This is the single most important step in preventing cracks.

Cutting Speed Optimization

Find the right balance between cutting speed and edge quality. Slower speeds will produce a smoother, more precise edge, which is ideal for intricate details. Faster speeds can be used for rougher cuts or less critical parts. Your machine’s software can help you determine the optimal speed for your specific job.

Lead-In and Lead-Out Strategy

Program a

What Safety Measures Are Essential for Waterjet Glass Cutting?

Operator Safety

All operators must be equipped with appropriate Personal Protective Equipment (PPE). This includes safety glasses or a face shield to protect from water spray and abrasive particles, hearing protection due to the noise of the high-pressure pump, and cut-resistant gloves for handling glass. Proper training on machine operation and safety procedures is mandatory.

Equipment Safety Features

VICHOR waterjet systems are designed with multiple safety features, including emergency stop buttons, pressure relief valves, and automatic shutdown mechanisms that activate if a fault is detected. These systems are designed to protect the operator and prevent damage to the machine.

Material Handling Safety

What Is the Cost of Waterjet Glass Cutting and Expected ROI?

Operating Costs

The primary operating costs for a waterjet system include water, electricity, and the abrasive material. A typical system will consume 3-5 liters of water per minute and a certain amount of abrasive depending on the cutting parameters. Maintenance costs, including replacing consumables like nozzles and seals, should also be factored in. The total operating cost can range from $50 to $150 per hour.

ROI Factors

The return on investment from a VICHOR waterjet system is driven by several key factors:

-

Reduced Material Waste: The narrow kerf and part-nesting capabilities can save up to 40% on material costs.

-

Eliminated Secondary Finishing: The smooth edge quality produced by the waterjet eliminates the need for most grinding and polishing, saving significant labor costs.

-

Increased Productivity: The ability to cut complex parts quickly and even stack multiple sheets for simultaneous cutting dramatically increases output.

-

Higher-Value Project Capabilities: A waterjet allows you to take on more complex and profitable jobs that are impossible with other methods.

VICHOR Waterjet Glass Cutting Success Stories

Real-world results from our customers are the best testament to the power and reliability of VICHOR technology. Our systems have empowered businesses across numerous industries to improve their quality, efficiency, and creative capabilities.

Our glass designs take on a whole new look by using VICHOR waterjet because we’re able to cut much more complex designs. Before we purchased the waterjet machine, it used to take me hours to cut each design.

Frequently Asked Questions About Waterjet Cutting Glass

Can waterjet cut all types of glass?

VICHOR waterjet technology can cut virtually all glass types except for tempered and hot glass. This includes flat glass, laminated glass, bulletproof glass (up to 9″ thick), optical lenses, mirrors, borosilicate glass, crystal glass, and stained glass. The cold-cutting process with proportional pressure control (7,200-11,600 PSI for piercing) ensures crack-free results across different glass compositions and thicknesses from 1mm to 23cm. Tempered glass cannot be cut because its internal stress pattern causes it to shatter when the surface is breached. For all other glass types, waterjet cutting provides superior precision and a smooth edge finish.

How much does waterjet glass cutting cost?

Waterjet glass cutting costs vary based on several factors: glass thickness, design complexity, cutting time, and abrasive consumption. Typical operating costs range from $50 to $150 per hour. While the initial equipment investment is substantial, the ROI typically occurs within 18-36 months through reduced material waste (up to 40% savings), the elimination of most secondary finishing, and increased production capacity. VICHOR’s efficient technology helps minimize operating costs, reducing the cost-per-part and making your operations more profitable.

Is waterjet cutting safe for delicate glass?

Yes, waterjet cutting is exceptionally safe for delicate glass due to VICHOR’s proportional pressure control technology. The process begins with a very low pressure during the critical piercing phase, then gradually ramps up. This controlled approach prevents the shock that causes cracks in fragile materials. The cold-cutting process also eliminates thermal stress, a major cause of failure in laser cutting. This makes waterjet the ideal method for cutting thin decorative glass, optical lenses, and mirrors without risk of damage.

What is the thickest glass a waterjet can cut?

VICHOR waterjet systems can cut glass up to 9 inches (23 centimeters) thick, which significantly exceeds the industry standard of 2-4 inches. This makes our technology ideal for specialty applications like multi-layered bulletproof glass, thick architectural panels, and heavy-duty structural glass. Our heavy-duty intensifier pumps and robust cutting heads deliver consistent performance and precision across the entire thickness range.

How does waterjet compare to laser cutting for glass?

Waterjet and laser cutting serve different purposes. Waterjet excels for thick glass (up to 9″ vs. laser’s 1″ limit) and completely eliminates the heat-affected zones that can cause stress and discoloration. Laser cutting can be faster on very thin glass, but its use of heat makes it unsuitable for many glass types. For versatility, edge quality, and the ability to cut thick materials, waterjet is the superior technology.

Can waterjet cut tempered glass?

No, waterjet cannot cut tempered glass. No cutting method can. Tempered glass is designed to shatter into small pieces when its surface is broken, which is a safety feature. All cutting and shaping must be performed before the glass undergoes the tempering process. VICHOR waterjet is the perfect tool for precisely shaping the glass before it is sent for tempering.

What pressure is needed to cut glass with waterjet?

VICHOR systems use variable pressure. The initial pierce is done at a low pressure of 7,200-11,600 PSI to prevent cracking. Once the pierce is complete, the pressure is ramped up to a cutting pressure of 50,000-87,000 PSI, depending on the glass thickness. This proportional pressure control is a VICHOR innovation and is critical for achieving crack-free results on glass.

How long does it take to cut glass with waterjet?

Cutting time depends on the thickness of the glass and the complexity of the design. A simple straight cut in thin glass (3-6mm) can proceed at 200-500 mm/min. For intricate designs or thick glass (over 50mm), the speed is reduced to 50-100 mm/min to ensure precision and a smooth edge. While this may seem slow, it is dramatically faster than manual methods and the high-quality result eliminates hours of secondary finishing work.

Do I need to polish glass edges after waterjet cutting?

In most cases, no. Waterjet cutting, especially when using a fine olivine abrasive, produces a smooth, satin-finished edge that is ready for use in most applications. This is a major advantage over traditional scoring, which leaves a sharp, rough edge requiring extensive grinding and polishing. The elimination of this secondary process saves significant time and labor costs.

What abrasive is best for cutting glass?

For the best edge quality on glass, olivine abrasive (80-120 mesh) is optimal. Its softer composition reduces micro-chipping and produces a naturally polished finish. Garnet is a harder abrasive that can cut faster but may result in a slightly rougher edge. VICHOR can provide expert guidance on selecting the perfect abrasive for your specific needs, balancing speed, quality, and cost.