Water Jet Tech: Transforming Modern Manufacturing with Precision and Power

Imagine a cutting technology so versatile that it can slice through titanium, glass, and rubber with the finesse of a surgeon’s scalpel, all while leaving no heat-affected zones or toxic residues. This isn’t science fiction—it’s the reality of water jet tech, a groundbreaking method that harnesses the raw force of water to revolutionize industries worldwide. From aerospace to art, water jet tech is redefining what’s possible in fabrication and design. In this article, we’ll dive deep into how this innovative technology works, its myriad benefits, and why it’s becoming the go-to solution for precision cutting. Whether you’re an engineer, a designer, or simply curious about advanced manufacturing, you’ll discover why water jet tech is making waves across the globe.

What is Water Jet Technology?

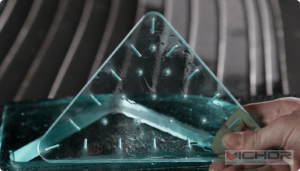

Water jet technology, often referred to as water jet tech, is an advanced cutting process that utilizes a high-pressure stream of water—sometimes mixed with abrasive materials—to cut through a wide range of substances. At its core, water jet tech relies on the principle of erosive force, where water is pressurized to extreme levels (often exceeding 60,000 psi) and directed through a small nozzle to create a focused jet. This jet can clean, shape, or cut materials with exceptional accuracy. The origins of water jet tech date back to the 1970s, when it was initially used for mining and forestry, but it has since evolved into a sophisticated tool for modern manufacturing. Unlike traditional methods that involve blades or heat, water jet tech operates cold, making it ideal for temperature-sensitive materials. Essentially, water jet tech transforms ordinary water into a powerful tool that combines environmental friendliness with unmatched precision, positioning it as a key player in the future of industrial processes.

How Does Water Jet Tech Work?

The operation of water jet tech involves a series of precise steps that convert water into a high-velocity cutting tool. First, water is drawn from a standard supply and filtered to remove impurities, ensuring a clean stream. It then enters an intensifier pump, which pressurizes it to levels ranging from 30,000 to 90,000 psi. This high-pressure water is forced through a small orifice, typically made of sapphire or diamond, to form a coherent jet traveling at speeds up to three times the speed of sound. In cases where harder materials like metals or ceramics need cutting, abrasive particles (such as garnet) are introduced into the stream via a mixing tube, enhancing the cutting power. The resulting abrasive water jet can slice through virtually any material, while pure water jet tech (without abrasives) is used for softer substances like foam or food products. Computer numerical control (CNC) systems guide the nozzle along predefined paths, allowing for intricate designs and repeatable accuracy. This process highlights the efficiency of water jet tech, as it minimizes waste and eliminates thermal distortion, making it a sustainable choice for diverse applications.

Key Advantages of Water Jet Tech

One of the standout features of water jet tech is its ability to cut without generating heat, which sets it apart from laser or plasma cutting methods. This cold-cutting process prevents material hardening, warping, or micro-cracking, preserving the integrity of sensitive substrates like composites or heat-treated metals. Additionally, water jet tech is highly versatile—it can handle materials of varying thicknesses, from thin plastics to thick steel plates, without requiring tool changes. Environmental benefits are another major advantage; since it uses water and natural abrasives, water jet tech produces no hazardous fumes or dust, aligning with green manufacturing standards. The precision of water jet tech is remarkable, with tolerances as tight as ±0.1 mm, enabling complex shapes and fine details that other methods struggle to achieve. Moreover, it reduces material waste through optimized nesting and omits the need for secondary finishing steps, saving time and costs. Overall, the adaptability and eco-friendliness of water jet tech make it a cost-effective solution for industries aiming to enhance productivity while minimizing their ecological footprint.

Applications of Water Jet Technology

Water jet tech finds applications across a broad spectrum of industries, thanks to its flexibility and precision. In the aerospace sector, it is used to cut lightweight alloys and composites for aircraft components, ensuring strength without adding weight. The automotive industry relies on water jet tech for shaping gaskets, interior panels, and custom parts, where accuracy is critical for safety and performance. Art and architecture have embraced water jet tech for creating intricate sculptures, decorative tiles, and architectural elements from materials like marble and glass, allowing artists to push creative boundaries. In the food industry, pure water jet tech is employed for slicing fruits, vegetables, and baked goods hygienically, without contamination. Furthermore, water jet tech plays a vital role in electronics manufacturing for precision cutting of circuit boards and insulation materials. Even in medical device production, it helps fabricate implants and instruments with sterile, burr-free edges. This widespread adoption underscores how water jet tech is not just a niche tool but a transformative force driving innovation in multiple fields.

The Future of Water Jet Tech

As technology advances, water jet tech is poised for even greater innovations that will expand its capabilities and accessibility. Researchers are focusing on improving energy efficiency by developing smarter pumps and recycling systems for water and abrasives, reducing operational costs and environmental impact. The integration of artificial intelligence and IoT (Internet of Things) into water jet tech is another exciting trend, enabling predictive maintenance, real-time monitoring, and automated adjustments for optimal performance. In the coming years, we can expect water jet tech to become more compact and user-friendly, making it accessible to smaller workshops and DIY enthusiasts. Advances in nozzle design and abrasive delivery may also enhance cutting speeds and surface quality, rivaling traditional methods in efficiency. Moreover, as sustainability gains importance, water jet tech could see increased use in recycling processes, such as disassembling electronic waste or repurposing materials. Ultimately, the evolution of water jet tech will likely lead to smarter, greener manufacturing ecosystems, solidifying its role as a cornerstone of Industry 4.0.

Common Questions About Water Jet Tech

Q1: What is water jet tech used for primarily?

A1: Water jet tech is primarily used for precision cutting, shaping, and cleaning of various materials, including metals, composites, stone, and food. Its ability to handle diverse substances without heat damage makes it ideal for industries like aerospace, automotive, and art, where accuracy and material integrity are crucial.

Q2: How does water jet tech compare to laser cutting?

A2: Unlike laser cutting, which uses heat and can cause thermal distortion, water jet tech is a cold-cutting process that avoids heat-affected zones. Water jet tech is also more versatile, as it can cut reflective or thick materials that lasers might struggle with, though laser cutting may be faster for thin metals in some cases.

Q3: Is water jet tech environmentally friendly?

A3: Yes, water jet tech is considered environmentally friendly because it uses water and natural abrasives, producing no toxic fumes or hazardous waste. Additionally, water can often be filtered and reused, minimizing consumption and aligning with sustainable manufacturing practices.

Q4: What materials can water jet tech not cut?

A4: Water jet tech can cut most materials, but it may be less effective on tempered glass or diamonds due to their hardness, which could cause excessive wear on the equipment. However, with advanced abrasives and adjustments, even these challenges are being addressed in newer systems.

Q5: How expensive is it to implement water jet tech?

A5: The cost of implementing water jet tech varies based on system size and features, but it generally involves an initial investment in pumps, nozzles, and CNC controls. Over time, it can be cost-effective due to reduced waste, lower energy consumption, and minimal need for secondary processing, making it a valuable long-term solution for many businesses.

In conclusion, water jet tech represents a fusion of power and precision that is reshaping modern manufacturing. From its cold-cutting prowess to its eco-friendly credentials, this technology offers a compelling alternative to conventional methods. As we look ahead, the ongoing advancements in water jet tech promise to unlock new possibilities, driving efficiency and creativity across industries. Whether you’re exploring it for industrial use or personal projects, understanding water jet tech is key to staying ahead in a rapidly evolving world.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read