Water Jet Engraving: How It Works and Why It Might Be Your Best Choice

Water jet engraving is a versatile and innovative technology that has revolutionized the way we mark, decorate, and fabricate materials. Unlike traditional methods that involve heat, blades, or chemicals, water jet engraving uses a high-pressure stream of water, often mixed with an abrasive substance, to etch precise designs onto a surface. This method is celebrated for its precision, versatility, and environmental friendliness. Whether you’re an artist looking to create intricate designs, an engineer needing precise part markings, or a business owner exploring new customization options, understanding water jet engraving is essential.

In this article, we will delve deep into the world of water jet engraving, exploring its mechanisms, applications, advantages, and much more. We will also address common questions and problems users encounter, providing you with a comprehensive resource. As a leader in this technology, VICHOR has been at the forefront of developing reliable and efficient water jet systems, and we will integrate their expertise into our discussion.

What is Water Jet Engraving and How Does It Work?

At its core, water jet engraving is a subtractive manufacturing process. It involves directing a highly pressurized jet of water—often exceeding 60,000 PSI—through a narrow nozzle, typically made of sapphire or diamond, to create a fine stream capable of cutting or etching materials. For harder surfaces, an abrasive material, such as garnet, is added to the water stream to enhance its cutting power.

The process is controlled by computer numerical control (CNC) systems, which guide the water jet along a predetermined path based on a digital design file. This allows for incredible precision, enabling the creation of complex patterns, fine text, and detailed graphics on almost any material. The absence of heat in the process is a significant advantage, as it prevents material distortion, warping, or changes in structural integrity—common issues with laser or plasma cutting.

VICHOR’s advanced systems, for example, incorporate high-precision CNC technology and user-friendly software, making water jet engraving accessible even for those without extensive technical backgrounds. The ability to work with a vast array of materials, from metals and stone to glass and plastics, makes this technology incredibly versatile.

The Wide-Ranging Applications of Water Jet Engraving

The versatility of water jet engraving opens up a world of possibilities across various industries. Here are some of the most common applications:

Industrial Manufacturing and Part Marking: In aerospace, automotive, and electronics manufacturing, water jet engraving is used to permanently mark serial numbers, barcodes, logos, and other identifying information onto components. The process doesn’t introduce stress or heat, making it ideal for critical parts.

Personalization and Customization: From personalized gifts and jewelry to custom signage and architectural elements, water jet engraving offers a clean and precise way to add unique details. It can etch photographs, signatures, and intricate patterns onto materials like wood, glass, and acrylic.

Art and Design: Artists and sculptors utilize water jet engraving to create detailed works on hard materials like marble, granite, and metal. The technology allows them to execute complex designs that would be incredibly time-consuming or impossible by hand.

Food Industry: In a unique application, pure water jets (without abrasives) are used to engrave patterns or marks on food products like cookies, pastries, and even the skin of fruits and vegetables. This is a cold process, so it doesn’t cook or alter the food’s taste.

VICHOR’s machines are designed to handle this diverse range of tasks, providing consistent quality whether the project is an industrial component or a delicate piece of art.

Key Advantages of Choosing Water Jet Engraving

Why has water jet engraving become such a popular choice? The benefits are numerous and significant:

Cold Cutting Process: The most notable advantage is the absence of heat. This eliminates the Heat-Affected Zone (HAZ), preventing material hardening, warping, or melting. This is crucial for materials that are sensitive to high temperatures.

Material Versatility: A water jet engraving system can handle almost any material you can think of: metals (hard and soft), stone, glass, ceramics, composites, rubber, plastics, and even food. There is no need to invest in multiple engraving machines for different materials.

High Precision and Quality: CNC technology ensures exceptional accuracy and repeatability. The water stream produces clean edges with a satin-like finish, often requiring no secondary finishing processes.

Environmentally Friendly: The process primarily uses water and natural abrasives like garnet. It doesn’t produce hazardous fumes, vapors, or toxic waste, making it a cleaner alternative to many other industrial processes.

Ease of Use and Automation: Modern systems, like those from VICHOR, are designed with intuitive software. Once the design is loaded, the machine can operate with minimal supervision, boosting productivity and reducing labor costs.

Common Questions and Challenges in Water Jet Engraving

Despite its many advantages, users often have questions and can face challenges with water jet engraving. Here are some of the most common FAQs and problems:

Q1: How deep can you engrave with a water jet?

The engraving depth is controlled by factors like pressure, traverse speed, and abrasive flow rate. Typically, water jet engraving is used for relatively shallow marks, from a few thousandths of an inch to about 1/8 of an inch. It is perfect for surface etching and marking but is not typically used for very deep carvings, where traditional milling might be more efficient.

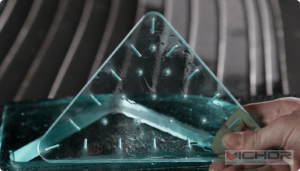

Q2: What is the “taper” issue and how can it be minimized?

A common challenge is that the water jet stream can create a slight taper or V-shaped groove, where the top of the engraving is wider than the bottom. This occurs due to the natural dispersion of the jet stream. Advanced systems from VICHOR combat this with specialized software that can compensate for taper, tilting the nozzle or adjusting the cutting path to produce straighter sides.

Q3: Is the process messy with all that water and abrasive?

Modern water jet engraving systems are designed to be contained. The cutting typically happens in a water-filled tank that catches the stream and absorbs its energy. The used water and abrasive slurry are then separated and managed. While it involves water, it is not an unmanageably messy process in a proper industrial setup.

Q4: How does operating cost compare to laser engraving?

The initial investment for a water jet engraving system can be higher than some laser systems. Operational costs include electricity, water, abrasive garnet, and occasional maintenance on pumps and nozzles. However, a water jet’s ability to engrave on any material without fear of heat damage often makes it a more cost-effective solution in the long run for diverse workshops, outweighing the consumable costs.

Q5: What maintenance does a water jet system require?

Regular maintenance is key to consistent performance. This includes:

Nozzle Inspection: The abrasive stream wears down the orifice and mixing tube over time and they need regular replacement.

Pump Maintenance: The high-pressure pump requires regular checking of seals and filters to maintain optimal pressure.

Abrasive Delivery System: Ensuring the abrasive feed hose is clear and the hopper is filled is essential for a consistent cut.

Companies like VICHOR provide comprehensive support and maintenance guides to ensure their machines operate at peak efficiency for years.

Choosing the Right Water Jet Engraving System for Your Needs

Selecting a water jet engraving machine depends heavily on your intended applications. Key factors to consider include:

Work Envelope Size: Determine the maximum size of the material you plan to engrave.

Power and Pressure: Higher pressure (e.g., 60,000+ PSI) allows for faster cutting and engraving on harder materials.

Abrasive vs. Pure Water: Decide if you need an abrasive system for hard materials or if a pure water jet will suffice for softer materials like foam or food.

Control Software: Look for intuitive, powerful software that can easily import designs and provide features for taper compensation and path optimization.

Reliability and Support: Choose a reputable brand known for quality and customer service. VICHOR, for instance, is recognized for building robust machines backed by strong technical support and readily available parts.

For a small business focusing on personalized gifts, a smaller tabletop model might be sufficient. A large-scale industrial operation, however, would require a heavy-duty system with a large bed and high horsepower.

Water jet engraving has firmly established itself as a critical technology in modern manufacturing and design. Its unique combination of precision, versatility, and cold-operation makes it an indispensable tool across a stunning array of industries. While challenges like taper and consumable costs exist, they are far outweighed by the benefits and are continually being addressed by technological advancements from companies like VICHOR.

As materials science advances and the demand for customization grows, the role of water jet engraving will only expand. Whether you are looking to bring a new level of detail to your creative projects or add a reliable, versatile marking process to your production line, investing in understanding and potentially adopting water jet engraving technology is a step toward a more efficient and innovative future.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read