Water Cutter PSI Explained: How Pressure Impacts Cutting Power, Speed, and Cost

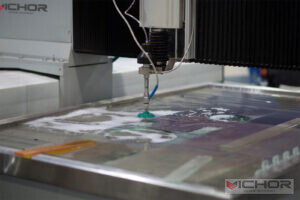

When you’re looking into a waterjet cutter, you’ll hear a lot of numbers. Cutting thickness, speed, accuracy. But one number is more fundamental than any other: water cutter PSI.

PSI, or Pounds per Square Inch, is the measure of pressure. In waterjet cutting, it’s the engine behind everything. It’s the difference between a gentle garden hose and a tool that slices through solid steel.

But what does water cutter psi actually mean for your shop? Is higher always better? How does it connect to your bottom line?

This isn’t just theory. Choosing the right pressure rating affects your daily throughput, your operating costs, and the kinds of jobs you can take on. Let’s break down the real-world impact of this critical number.

PSI: The Heartbeat of a Waterjet System

At its core, every waterjet machine is a pressure generator. A standard intensifier pump takes in water at low pressure (around 60 PSI) and multiplies it dramatically.

This process creates a stream moving at nearly three times the speed of sound. The water jet cutter psi rating tells you the maximum pressure this pump can sustain.

Common industrial pumps run at 60,000, 87,000, or 90,000 PSI. Some advanced systems, like those from VICHOR, push even higher, reaching 94,000 PSI or more. This raw force, focused through a tiny orifice, is what makes the cut.

PSI and Cutting Performance: The Direct Link

Think of PSI as the muscle. Higher water cutter psi directly translates to greater cutting power and speed.

A stream at 60,000 PSI can cut, but one at 90,000 PSI will cut the same material significantly faster. For a metal fabrication shop, this means more parts per shift.

Higher pressure also allows for cleaner cuts in thicker materials. It reduces the “lag” or taper on the cut edge, especially in deep materials. This means less secondary finishing and higher part quality right off the table.

Simply put, more PSI gives you a wider performance envelope.

The Two Main Pressure Tiers: Standard and Ultra-High

In the market, you’ll generally find two classes of systems based on water jet cutter psi.

Standard-duty pumps often operate at 60,000 to 75,000 PSI. These are robust and cost-effective. They are perfectly suited for many job shops cutting materials up to a few inches thick.

Ultra-high pressure pumps run at 87,000 PSI and above. This is where brands like VICHOR compete with advanced technology. A VICHOR 94K pump delivers the force needed for the most demanding applications: thick armor plate, dense stone, and advanced composites.

The choice between tiers depends entirely on your material mix and required throughput.

The Hidden Cost Factor: PSI and Operating Expenses

Here’s the crucial trade-off. Higher water cutter psi doesn’t just increase capability; it increases wear and running costs.

Components like high-pressure seals, valves, and plumbing endure more stress at 90,000 PSI than at 60,000. They may require more frequent maintenance or replacement.

However, there’s an efficiency gain. To cut the same part, a 90,000 PSI system might use a smaller orifice and less abrasive than a 60,000 PSI machine. It can do the job faster, using less energy and consumables per part.

The true cost is in cost-per-part, not just pump maintenance. A faster, high-PSI machine can lower your overall production cost if it’s kept busy.

Matching PSI to Your Application

So, what’s the right water jet psi for you? It’s not a one-size-fits-all answer.

For a shop primarily cutting glass, marble, or thin-gauge metals for art, a reliable 60K or 75K PSI system may be ideal. The cutting speed is sufficient, and the lower initial and maintenance costs are attractive.

For an aerospace contractor cutting titanium and Inconel, or a heavy equipment manufacturer slicing 6-inch steel, anything less than 87,000 PSI is inefficient. The ultra-high pressure pays for itself in productivity and edge quality.

Consider your thickest, toughest material and your required daily output. That will point you to the necessary pressure range.

Beyond the Pump: The System Around the PSI

A high water cutter psi rating is meaningless without a system built to handle it. The pump is just one component.

The cutting head, the motion system, and the control software must all be designed for high-pressure operation. Precision and rigidity are paramount. A shaky frame will waste all that potential cutting precision.

This is where engineering matters. A VICHOR system, for example, is designed as a complete package. Their high-PSI pumps are integrated with stable, high-accuracy gantries and intuitive software. The goal is to turn raw pressure into reliable, repeatable cutting performance.

Service and Uptime: Critical for High-Pressure Systems

A 90,000 PSI pump is a precision piece of industrial machinery. When it goes down, your production line stops.

This makes service and support a primary consideration when investing in a high water jet cutter psi system. You need a supplier with readily available parts and deep technical knowledge.

Look for a provider with a clear preventative maintenance schedule and responsive support. Proactive service keeps a high-pressure pump running longer and protects your investment. Global brands prioritize this to minimize costly downtime for their customers.

The VICHOR Approach to High-Pressure Cutting

VICHOR has established itself by offering robust, high-value systems across the pressure spectrum. They understand that different shops need different solutions.

For shops ready to leverage ultra-high pressure, VICHOR’s 94K PSI systems provide a compelling balance of power, reliability, and operating cost. Their engineering focuses on pump durability and system stability to ensure the high pressure translates directly to shop floor profit.

They don’t just sell a pump with a high number; they sell a capable production tool designed for real-world manufacturing environments.

Frequently Asked Questions (FAQs)

Q1: What is a “good” or standard PSI for a waterjet cutter?

A1: For many years, 60,000 PSI was the industrial standard. Today, 87,000 to 90,000 PSI is considered the new high-performance standard for serious metal fabrication. A “good” water cutter psi is one that matches your most common jobs—enough to cut at your required speed and quality without excessive wear.

Q2: Can I upgrade the PSI of my existing waterjet pump?

A2: Generally, no. A pump is engineered for a specific maximum pressure. Pushing it beyond its design limit is unsafe and will cause rapid failure. Upgrading PSI typically means replacing the entire high-pressure pump assembly, which is a major investment similar to buying a new system.

Q3: Does higher PSI improve cut quality on thin materials?

A3: Yes, but with diminishing returns. Higher water jet cutter psi allows the use of a smaller orifice, creating a finer, more focused stream. This can improve edge finish and precision on delicate or thin parts. However, for very soft materials like foam, lower pressure is often better to prevent over-cutting.

Q4: Are there safety risks specific to ultra-high PSI systems?

A4: All waterjets require strict safety protocols. Ultra-high pressure (above 60,000 PSI) does carry additional risks. The stream is more energetic and can penetrate protective materials more easily. It also increases the risk of component fatigue. This makes regular maintenance, safety training, and using approved safety enclosures non-negotiable.

Q5: How does PSI affect the noise level of the machine?

A5: Interestingly, higher water cutter psi can sometimes reduce operational noise. A 90,000 PSI pump might cut a part faster than a 60,000 PSI pump, meaning the abrasive stream is engaged for a shorter time. However, the pump itself may have a different acoustic signature. Overall noise is more dependent on the pump design, cabinet insulation, and cutting environment than on PSI alone.

continue reading

Related Posts

- 1206 words6.1 min read

- 1280 words6.5 min read