Unlock Complex Designs: The Power of 5 Axis Waterjet Cutting Services for Precision Cutting Solutions

In the relentless pursuit of manufacturing excellence, the ability to shape complex geometries from virtually any material is paramount. Traditional cutting methods often hit limitations when faced with intricate contours, thick sections, or delicate substances. This is where the remarkable capabilities of 5 axis waterjet cutting services come into play, revolutionizing precision fabrication. By harnessing the power of ultra-high-pressure water, often mixed with abrasive garnet, and manipulating the cutting head through five distinct axes of motion, these advanced systems unlock unprecedented design freedom and manufacturing efficiency. This article delves deep into the world of 5 axis waterjet cutting services, exploring five key aspects that make them an indispensable tool for modern industry.

1. Understanding the Core Technology: What Makes 5 Axis Waterjet Cutting Unique

At its heart, waterjet cutting utilizes a supersonic stream of water (typically pressurized between 60,000 and 90,000+ PSI) to erode material. In abrasive waterjet cutting, fine garnet particles are introduced into this stream, transforming it into an incredibly potent cutting tool capable of slicing through metals, composites, stone, glass, and more with remarkable precision.

The true differentiator of 5 axis waterjet cutting services lies in the mobility of the cutting head. Unlike traditional 3-axis machines (X, Y, Z linear movements), 5-axis systems add two rotational axes:

A-axis (Tilt): Rotation around the X-axis, allowing the head to tilt forward and backward.

C-axis (Rotation): Rotation around the Z-axis, allowing the head to swivel clockwise and counter-clockwise.

This multi-directional capability allows the cutting head to approach the workpiece from virtually any angle. The nozzle maintains a consistent, optimal standoff distance and perpendicularity to the cut surface, even on complex 3D contours. This eliminates the “taper” or “kerf angle” inherent in 3-axis cuts on bevels and angles, resulting in true precision geometry. 5 axis waterjet cutting services essentially bring the capabilities of multi-axis machining centers to the cold-cutting, stress-free world of waterjet technology.

2. Unparalleled Material Versatility and Capability

One of the most significant advantages offered by 5 axis waterjet cutting services is their near-universal material compatibility. The abrasive waterjet process is fundamentally a mechanical erosion process, not thermal. This means it doesn’t melt, warp, or create a Heat-Affected Zone (HAZ), preserving the material’s intrinsic properties. This cold-cutting nature makes it ideal for:

Metals: From delicate aluminum and copper foils to thick titanium, tool steels, Inconel, brass, and hardened armor plate (often exceeding 12 inches thick).

Composites: Carbon fiber, fiberglass, Kevlar, and laminates are cut cleanly without delamination, fraying, or thermal degradation – a critical factor in aerospace and automotive applications.

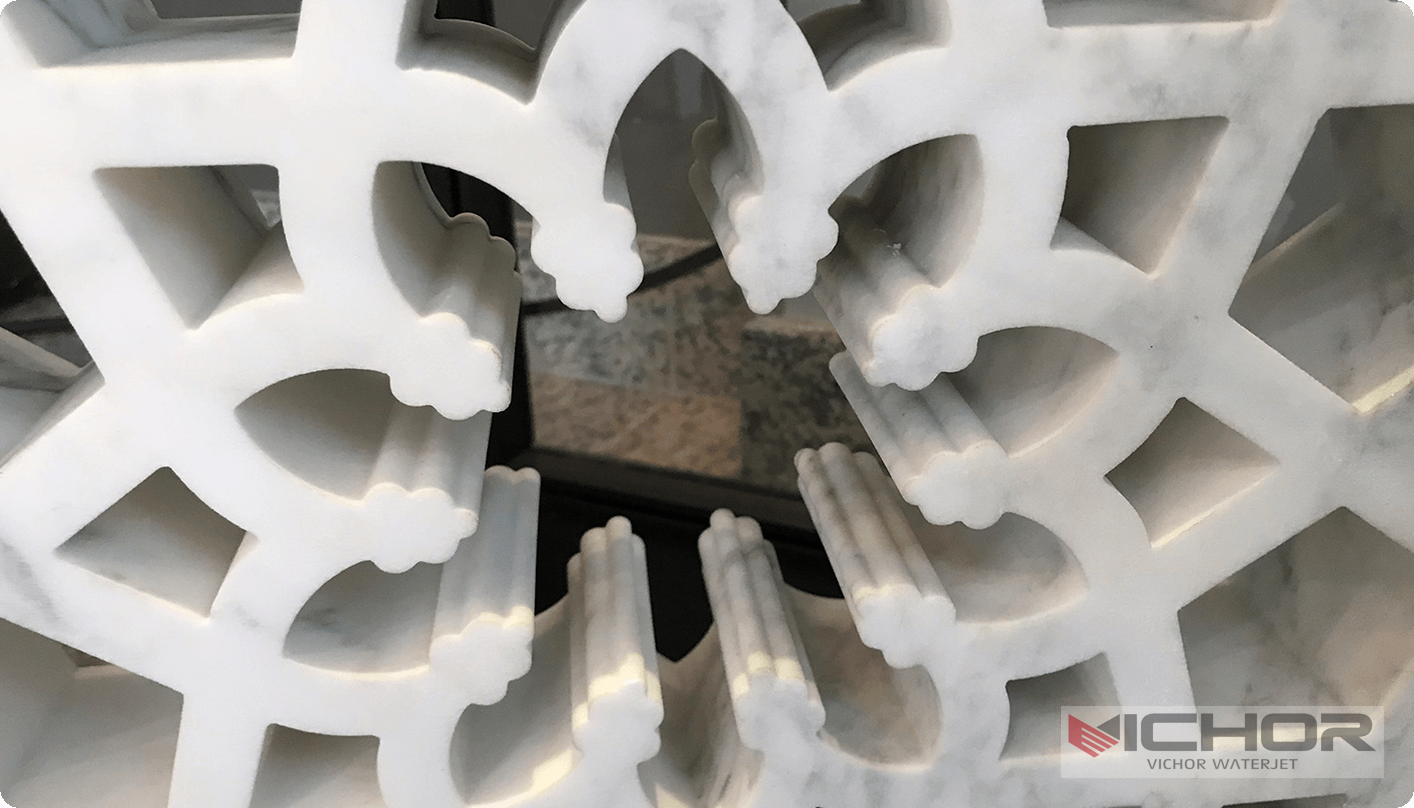

Stone and Tile: Precise cutting of granite, marble, quartz, porcelain, and ceramic for intricate architectural features, countertops, and artistic inlays.

Glass: Cutting complex shapes in float glass, laminated glass, tempered glass (prior to tempering), and even bulletproof glass without cracking or chipping.

Plastics and Polymers: Acrylics, polycarbonate, PVC, HDPE, UHMW, and rubber, avoiding melting or toxic fumes.

Exotic Materials: Foam, gaskets, honeycomb structures, food products, and even sensitive electronics components.

5 axis waterjet cutting services handle this vast array without requiring tool changes or extensive process adjustments between materials. The primary variables are pressure, abrasive flow rate, traverse speed, and nozzle selection, all easily controlled by the CNC system.

3. Achieving Complex Geometries and Precision with Zero Taper

The defining benefit of utilizing 5 axis waterjet cutting services is the ability to produce highly complex 3D shapes and beveled edges with exceptional accuracy and zero taper. This is crucial for numerous applications:

Precision Beveling: Creating perfect weld preparation bevels (V-grooves, J-grooves, compound angles) on thick plates for critical structural components, pressure vessels, and shipbuilding. The 5-axis head dynamically adjusts to maintain the exact angle along the entire contour.

3D Contouring: Cutting intricate shapes that are not flat or have varying slopes and curves in three dimensions, such as turbine blades, impellers, sculptural elements, and complex molds.

True Shape Cutting: Eliminating the geometric distortion caused by taper in 3-axis cutting, ensuring parts fit together perfectly the first time, especially critical for tight-tolerance assemblies.

Undercuts and Features: Creating features that would be impossible or extremely difficult with traditional machining or 3-axis waterjet, such as internal undercuts or features requiring angled access.

Reduced Secondary Operations: By producing parts with finished edges and precise angles directly off the machine, 5 axis waterjet cutting services drastically reduce or eliminate the need for costly secondary machining, grinding, or milling operations, saving significant time and money.

The precision achievable is typically within +/- 0.003″ to +/- 0.005″ for positioning and contouring, making it suitable for demanding aerospace, medical, and energy sector components.

4. Key Industries and Applications Leveraging 5 Axis Waterjet

The unique capabilities of 5 axis waterjet cutting services make them indispensable across a wide spectrum of high-tech and demanding industries:

Aerospace & Defense: Manufacturing complex titanium and Inconel components, engine parts, composite airframe structures, radomes, and intricate brackets with strict tolerances and no thermal stress. Beveling thick armor plate is another critical application.

Energy (Oil & Gas, Nuclear, Renewable): Cutting thick-wall pressure vessels, pipe ends for welding preparation (including complex J-preps), flanges, turbine components (hydro, wind, steam), and heat exchanger parts. The ability to handle exotic alloys and provide stress-free cuts is vital.

Architecture, Engineering & Construction (AEC): Creating intricate stone and tile features, complex metal facades and cladding panels, structural steel connections with bevels, artistic metalwork, and large-scale composite elements.

Automotive & Motorsport: Prototyping complex parts, cutting composite body panels and aerodynamic elements, fabricating specialized brackets and chassis components, and working with high-strength steels and aluminum.

Marine & Shipbuilding: Precise beveling of thick hull plates for welding, cutting complex structural components, and fabricating parts from various metals and composites.

Industrial Machinery: Manufacturing large gears, sprockets, complex machine frames, and wear parts with intricate profiles and beveled edges.

Medical Device Manufacturing: Producing precision components from titanium, stainless steel, and specialized plastics for implants and surgical instruments, benefiting from the cold, burr-free cut.

5. The Economic and Process Advantages of Partnering with a 5 Axis Service

Choosing professional 5 axis waterjet cutting services offers compelling advantages over in-house investment or relying on less capable methods:

Elimination of Capital Investment: 5-axis waterjet machines represent a significant capital expenditure. Outsourcing provides access to this cutting-edge technology without the upfront cost, maintenance overhead, or operator training requirements.

Access to Expertise: Reputable service providers possess deep knowledge of material behavior, cutting strategies, nesting optimization, and fixturing for complex parts. They can advise on design for manufacturability (DFM) to optimize cost and quality.

Speed and Flexibility: Service bureaus are geared for rapid turnaround, from prototype to production. They handle diverse jobs efficiently, providing flexibility without tying up internal resources.

Reduced Material Waste & Cost Savings: Advanced nesting software maximizes material utilization on expensive stock. The elimination of secondary operations (like bevel machining) drastically reduces overall part cost and lead time.

Scalability: Easily scale production up or down based on project needs without impacting internal capacity.

Guaranteed Quality: Professional services invest in calibration, maintenance, and quality control processes to ensure parts meet stringent specifications consistently.

Focus on Core Competencies: Outsourcing complex cutting allows companies to focus their internal resources on core activities like design, assembly, and sales.

5 axis waterjet cutting services represent the pinnacle of versatility, precision, and capability in modern subtractive manufacturing. By combining the inherent benefits of cold, stress-free, material-agnostic waterjet cutting with the geometric freedom of 5-axis motion, these services unlock design possibilities previously unattainable or prohibitively expensive. From eliminating taper and achieving perfect bevels on thick materials to contouring complex 3D shapes across virtually any substance, the applications are vast and transformative across aerospace, energy, automotive, architecture, and beyond. Partnering with a skilled provider of 5 axis waterjet cutting services offers a strategic advantage, delivering high-precision parts efficiently, cost-effectively, and with the quality demanded by today’s most challenging industries. As manufacturing continues to push boundaries, 5 axis waterjet cutting services will remain a critical enabler of innovation and complex component fabrication.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read