Unleashing Creativity: How a Water Jet Foam Cutting Machine Transforms Design and Manufacturing

In the world of modern fabrication and design, precision, versatility, and efficiency are paramount. Among the various technologies that have risen to meet these demands, the water jet foam cutting machine stands out as a remarkably powerful and adaptable tool. This technology, which harnesses the immense power of water—sometimes combined with abrasives—has revolutionized how soft, lightweight materials like foam are shaped and utilized across countless industries. From intricate architectural models to custom packaging and bespoke artwork, the capabilities of a water jet foam cutting machine are redefining the boundaries of what is possible. This article delves deep into the core aspects of this technology, exploring its fundamental principles, unparalleled advantages, diverse applications, key technical considerations, and the future it is helping to shape. Whether you are a seasoned manufacturer, a designer, or simply curious about advanced cutting technologies, understanding the power of a water jet foam cutting machine is essential.

The Core Principle: How a Water Jet Foam Cutting Machine Actually Works

At its heart, a water jet foam cutting machine is a study in focused power. The process, known as water jet cutting, utilizes a high-pressure pump to pressurize water to extreme levels, often exceeding 60,000 PSI (Pounds per Square Inch). This ultra-high-pressure water is then forced through a tiny orifice, typically made of sapphire or diamond, creating a supersonic stream thinner than a human hair.

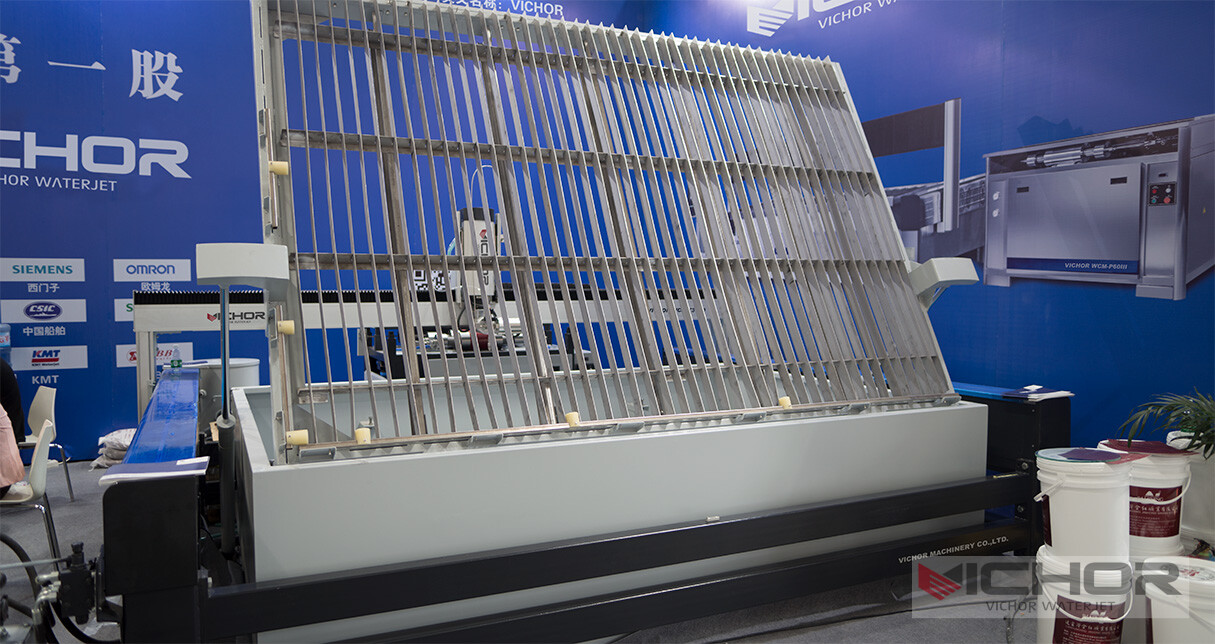

For cutting harder materials, an abrasive garnet is introduced into the stream just after the orifice. However, when it comes to cutting soft materials like polyurethane foam, EPS (Expanded Polystyrene), XPS (Extruded Polystyrene), and other polymer foams, the pure water jet is overwhelmingly sufficient. The stream impacts the foam material with immense kinetic energy, instantly eroding and washing away a tiny portion of the material. The cutting head is mounted on a sophisticated CNC (Computer Numerical Control) gantry system, which moves it along a pre-programmed path based on a digital design file (e.g., DXF or CAD). This allows for exceptionally precise, computer-controlled cuts, enabling the creation of shapes with complex geometries and tight tolerances that would be nearly impossible to achieve with manual methods.

Unmatched Advantages: Why Choose Water Jet for Foam Cutting?

The decision to utilize a water jet foam cutting machine is driven by a compelling set of advantages that directly address the challenges of working with foam materials.

Cold Cutting Process: Unlike laser or hot wire cutting, water jet cutting is a cold process. There is no heat-affected zone (HAZ). This is critical for foam, which is highly susceptible to melting, burning, or emitting harmful fumes when exposed to heat. A water jet foam cutting machine leaves a clean, smooth edge without any thermal deformation, preserving the material’s intrinsic properties.

Exceptional Precision and Repeatability: The CNC-guided water stream offers extraordinary accuracy, often within a tolerance of +/- 0.005 inches. This means every cut is perfect, and every part is identical to the last, which is invaluable for mass production and prototyping where consistency is non-negotiable.

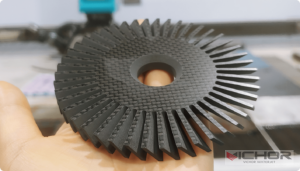

Versatility in Design and Material: The technology is not limited to straight lines or simple curves. It can effortlessly produce intricate 2D shapes, detailed patterns, and even 3D contours through multi-axis cutting heads. Furthermore, while specialized for foam, the same machine can often cut a vast array of other materials—plastics, rubber, fabrics, and even metals (with abrasive)—making it an incredibly flexible investment.

Material Efficiency and Reduced Waste: The narrow kerf (the width of the cut) of a water jet stream minimizes material waste. Nesting software can arrange parts to be cut from a single sheet of foam with optimal efficiency, saving on material costs and promoting sustainable manufacturing practices.

Clean and Environmentally Friendly: The process primarily uses water and, in the case of pure water jet cutting for foam, no added abrasives. The water can often be filtered and recycled within the system. It does not produce toxic gases or dust clouds, making it a cleaner and safer option for operators.

A World of Applications: Where is the Water Jet Foam Cutting Machine Used?

The unique capabilities of the water jet foam cutting machine have opened doors to innovation in a surprising variety of fields.

Packaging and Cushioning: Custom protective packaging for fragile, high-value items like medical equipment, electronics, and artworks. The water jet can create perfectly form-fitting foam inserts that provide superior protection during shipping and handling.

Architectural Modeling and Scale Prototyping: Architects and engineers use these machines to create highly detailed and accurate scale models of buildings, landscapes, and products from foam blocks. The speed and precision allow for rapid iteration of design concepts.

Signage, Props, and Scenic Art: The entertainment and advertising industries heavily rely on foam cutting for creating large-scale letters for signs, lightweight props for films and theaters, and intricate scenic elements for theme parks. The ability to cut complex 3D shapes is particularly prized here.

Composite Core Manufacturing: Many high-performance composites, used in aerospace, marine, and wind energy industries, use foam as a core material sandwiched between layers of fiberglass or carbon fiber. Water jets are used to precisely shape these foam cores before lamination.

Art and Sculpture: Artists embrace the water jet foam cutting machine as a digital tool for creation. It allows them to translate complex digital designs into tangible foam sculptures, which can serve as final pieces or as molds for casting other materials like bronze or concrete.

Key Technical Considerations When Using a Water Jet for Foam

While highly effective, operating a water jet foam cutting machine for foam requires attention to specific parameters to achieve optimal results.

Pressure and Flow Rate: Foam is a soft material, so it does not require the extreme pressures used for cutting metal. Often, lower pressures (e.g., 30,000-40,000 PSI) are used, which reduces wear on the pump and components and lowers operational costs.

Orifice and Nozzle Size: A smaller orifice size helps maintain a coherent, high-velocity stream ideal for fine details in foam. The focusing tube (also known as the nozzle) for pure water cutting is longer and narrower than its abrasive counterpart.

Cutting Speed and Feed Rate: One of the biggest advantages with foam is the incredible cutting speed. The water jet can move very quickly through the material, significantly reducing production time compared to cutting denser materials. The optimal speed must be calibrated to avoid under-cutting or over-cutting, which can affect edge quality.

Material Fixturing: Due to the force of the water stream, lightweight foam sheets or blocks must be properly secured to the cutting table to prevent movement during the cutting process. Vacuum tables are commonly used for this purpose, holding the material flat and stationary without mechanical clamps that might interfere with the cutting path.

Water Management and Drainage: The process generates a mist and water runoff. Effective tank systems and drainage are necessary to contain the water. While the water is generally clean, filtering systems are used to remove suspended foam particles before the water is recirculated or discharged.

Navigating the Market: Choosing the Right Water Jet Foam Cutting Solution

Selecting a water jet foam cutting machine is a significant decision. Key factors to consider include:

Table Size and Cutting Envelope: The machine’s size must accommodate the largest foam blocks or sheets you plan to work with.

CNC Controller and Software: User-friendly software is crucial for translating designs into machine commands. Look for systems with intuitive nesting and path optimization features.

Pump Type and Power: Direct-drive pumps are often sufficient for dedicated foam cutting applications and are more cost-effective and easier to maintain than intensifier pumps.

Durability and Support: Consider the machine’s construction quality and the manufacturer’s reputation for customer service and technical support.

The future of this technology points towards greater integration, with more advanced software for 3D modeling and cutting, increased automation for loading and unloading materials, and ever-improving energy and water efficiency.

The water jet foam cutting machine is far more than just a tool; it is a gateway to unprecedented levels of creativity and manufacturing efficiency. Its ability to cold-cut intricate shapes with pinpoint accuracy from delicate foam materials has made it an indispensable asset in workshops, factories, and design studios around the globe. By combining sheer power with digital precision, it solves long-standing challenges associated with foam fabrication, eliminating heat damage, reducing waste, and unlocking complex designs. As technology continues to advance, the role of the water jet foam cutting machine will only expand, continuing to empower innovators to cut, shape, and create the future, one precise stream of water at a time. For anyone looking to master the art and science of working with foam, embracing this technology is not just an option—it is a strategic advantage.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read