Types of Water Jets: A Detailed Analysis for Modern Applications

Water jet technology has revolutionized various industries by offering precise, efficient, and versatile cutting and cleaning solutions. Understanding the different types of water jets is crucial for selecting the right system for specific applications. This article delves into the various types of water jets, exploring their mechanisms, uses, and benefits. Whether you’re in manufacturing, construction, or any field requiring high-precision work, knowing about the type of water jet that suits your needs can enhance productivity and reduce costs. We will cover key aspects, including pure water jets, abrasive water jets, and other variants, to provide a comprehensive overview. By the end, you’ll have a clear understanding of how each type of water jet operates and where it excels.

What Are Water Jets and Why Do Types Matter?

Water jets are tools that use high-pressure streams of water to cut, clean, or shape materials. The concept dates back to the mid-20th century, but advancements have made them indispensable in modern industry. The core principle involves pressurizing water to extreme levels, often exceeding 60,000 psi, and directing it through a nozzle to create a focused stream. This stream can slice through materials ranging from soft fabrics to hard metals, depending on the type of water jet used. The importance of understanding the different types of water jets lies in their specialization; each type is designed for specific tasks, materials, and environments. For instance, some are ideal for delicate cutting without heat damage, while others handle rugged industrial cleaning. By grasping the distinctions, users can optimize performance, minimize waste, and ensure safety. This section sets the stage for a deeper dive into the primary categories of water jets, highlighting why selecting the right type of water jet is a critical decision in many operational contexts.

Pure Water Jets: Simplicity and Precision

Pure water jets represent one of the fundamental types of water jets, relying solely on high-pressure water without any additives. These systems are renowned for their simplicity and effectiveness in cutting soft materials. The mechanism involves pumping water to high pressures and ejecting it through a small orifice, typically made of sapphire or diamond, to maintain a consistent stream. This type of water jet excels in applications where precision and cleanliness are paramount, such as in food processing, where it cuts fruits, vegetables, or baked goods without contamination. Similarly, in the textile industry, pure water jets cleanly slice through fabrics, foam, and rubber, leaving smooth edges without fraying. One of the key advantages of this type of water jet is the absence of heat-affected zones, making it ideal for materials sensitive to temperature changes. However, pure water jets have limitations when dealing with hard substances like metals or ceramics, as the water alone may not generate sufficient force. This type of water jet is also favored for its environmental friendliness, as it uses only water and produces no hazardous waste. Maintenance involves regular nozzle checks and water filtration to prevent clogging, ensuring long-term reliability. Overall, pure water jets are a versatile option within the spectrum of water jet types, particularly suited for lightweight and non-metallic materials.

Abrasive Water Jets: Power and Versatility

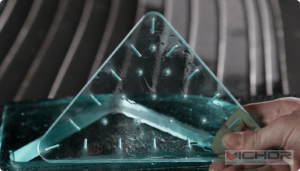

Abrasive water jets are a more robust type of water jet, incorporating abrasive materials like garnet or aluminum oxide into the water stream to enhance cutting power. This type of water jet is designed for challenging applications that involve hard materials, such as metals, stone, glass, and composites. The system works by mixing abrasives with high-pressure water in a mixing chamber before the stream exits the nozzle. This combination allows the abrasive water jet to erode and cut through thick, durable surfaces with remarkable accuracy. Industries like aerospace, automotive, and construction heavily rely on this type of water jet for tasks like shaping turbine blades, cutting automotive parts, or fabricating architectural elements. A significant benefit of this type of water jet is its ability to handle a wide range of material thicknesses without generating heat, which prevents structural weaknesses in the workpiece. However, abrasive water jets require more complex maintenance due to the abrasive particles, which can wear down components over time. Operators must monitor abrasive levels, nozzle integrity, and water quality to sustain efficiency. Despite these demands, this type of water jet offers unparalleled versatility, making it a go-to choice for heavy-duty operations. When considering the various types of water jets, the abrasive variant stands out for its adaptability and strength in diverse industrial settings.

Hybrid and Specialized Water Jet Types

Beyond the basic pure and abrasive categories, there are hybrid and specialized types of water jets that cater to niche applications. Hybrid systems combine elements of both pure and abrasive water jets, allowing operators to switch between modes based on the material. This type of water jet is increasingly popular in facilities that handle a mix of soft and hard materials, as it reduces the need for multiple machines. For example, a hybrid system might use pure water for cleaning surfaces and then switch to abrasive mode for cutting metal components. Another specialized type of water jet is the cavitating water jet, which utilizes controlled bubbles or cavitation to amplify cutting force without increasing pressure. This is useful in underwater operations or for materials that are sensitive to direct impact. Additionally, there are low-pressure water jets designed for gentle cleaning tasks, such as in historical restoration or medical device sterilization. These specialized types of water jets highlight the technology’s adaptability, with each variant engineered for specific challenges. When evaluating the type of water jet for a project, it’s essential to consider these hybrid and specialized options, as they can offer cost savings and improved efficiency in complex workflows. This diversity among types of water jets ensures that nearly every industrial need can be met with a tailored solution.

Applications Across Industries: Where Each Type of Water Jet Shines

The applications of different types of water jets span numerous industries, demonstrating their broad utility. In manufacturing, pure water jets are often used for cutting gaskets, insulation, and plastics, where precision and speed are critical. The food industry employs this type of water jet for portioning products like meat or cheese, ensuring hygienic and consistent results. Conversely, abrasive water jets dominate in metalworking, where they cut intricate shapes in steel, aluminum, or titanium without altering material properties. The construction sector uses this type of water jet for tasks like concrete demolition or tile cutting, reducing dust and noise compared to traditional methods. In aerospace, abrasive water jets fabricate components with tight tolerances, while in art and design, they enable detailed sculptures from materials like marble or glass. Environmental applications include using water jets for surface preparation in shipbuilding or pipeline cleaning, where minimal chemical use is a priority. Each type of water jet finds its niche based on the material hardness, required precision, and operational environment. By matching the type of water jet to the application, businesses can achieve higher quality outcomes, reduce material waste, and enhance safety. This section underscores how understanding the specific strengths of each type of water jet can lead to optimized processes across various fields.

Factors to Consider When Choosing a Type of Water Jet

Selecting the right type of water jet involves evaluating several factors to ensure it aligns with your project requirements. Material compatibility is paramount; soft materials like paper or foam may only need a pure water jet, while harder substances like metals require an abrasive type of water jet. Thickness also plays a role—thicker materials often demand abrasive systems for effective cutting. Another consideration is precision: if your work involves intricate designs, a pure water jet might suffice for delicate cuts, but an abrasive system offers finer control for complex patterns in tough materials. Cost is a significant factor; pure water jets generally have lower operating expenses due to the absence of abrasives, whereas abrasive systems involve ongoing costs for abrasive materials and part replacements. Operational environment matters too—for instance, in clean rooms or food-safe areas, a pure type of water jet is preferable to avoid contamination. Maintenance requirements vary; abrasive water jets need more frequent checks, so availability of technical support should influence your decision. Additionally, throughput and speed requirements might dictate the choice, as some types of water jets offer faster cutting rates for high-volume production. By carefully assessing these aspects, you can identify the most suitable type of water jet for your needs, balancing performance, cost, and longevity. This proactive approach ensures that the selected type of water jet delivers optimal results in your specific context.

Maintenance and Safety for Different Types of Water Jets

Proper maintenance and safety protocols are essential for all types of water jets to ensure longevity and prevent accidents. For pure water jets, routine tasks include inspecting nozzles for wear, filtering water to remove impurities, and checking pump systems for pressure consistency. Since this type of water jet relies on high-pressure water, leaks or ruptures can pose risks, so regular pressure tests and seal replacements are advised. Abrasive water jets require additional maintenance due to the abrasive particles; operators must monitor abrasive delivery systems, replace mixing tubes frequently, and clean out slurry residues to prevent blockages. Safety measures for any type of water jet include wearing protective gear like goggles and gloves, as the high-pressure stream can cause injuries. Training is crucial to handle emergencies, such as sudden pressure drops or nozzle failures. Environmental considerations, such as containing water runoff in abrasive systems, are also important to minimize ecological impact. By adhering to these practices, users can extend the life of their equipment and maintain a safe working environment. Whether dealing with a pure or abrasive type of water jet, a disciplined maintenance schedule reduces downtime and enhances reliability, making it a key aspect of operational success.

Future Trends in Water Jet Technology

The evolution of water jet technology continues to introduce innovations that expand the capabilities of various types of water jets. One emerging trend is the integration of smart controls and IoT features, allowing real-time monitoring and adjustments for improved efficiency. This could make each type of water jet more user-friendly and adaptive to changing conditions. Another development is the enhancement of abrasive recovery systems, reducing waste and costs for abrasive water jets. Researchers are also exploring new nozzle designs and water treatment methods to increase the lifespan of components across all types of water jets. Sustainability is a growing focus, with efforts to recycle water and use eco-friendly abrasives, aligning with global environmental standards. Additionally, advancements in pressure technology may lead to more compact and energy-efficient systems, making different types of water jets accessible to smaller businesses. As automation and robotics become more prevalent, we might see increased use of water jets in automated production lines, further boosting productivity. These trends indicate a bright future for water jet technology, with each type of water jet becoming more versatile, efficient, and sustainable. Staying informed about these developments can help industries leverage the full potential of their chosen type of water jet.

In summary, the various types of water jets offer tailored solutions for a wide array of industrial needs. From the simplicity of pure water jets to the power of abrasive systems, and the adaptability of hybrid models, each type of water jet has distinct advantages. By understanding these differences and considering factors like material type, application, and maintenance, users can make informed decisions that enhance efficiency and outcomes. As technology advances, the capabilities of each type of water jet will only grow, providing even more opportunities for innovation. We hope this analysis has shed light on the critical aspects of water jet types, empowering you to choose the best option for your projects.

Frequently Asked Questions

Q1: What is the main difference between pure water jets and abrasive water jets?

A1: The primary difference lies in their cutting mechanisms. Pure water jets use only high-pressure water and are ideal for soft materials like foam or food, while abrasive water jets mix abrasives into the water stream to cut hard materials such as metals or ceramics.

Q2: Can one machine handle both pure and abrasive water jet functions?

A2: Yes, hybrid water jet systems are available that can switch between pure and abrasive modes, offering flexibility for facilities that work with a variety of materials without needing separate machines.

Q3: How does the type of water jet affect operating costs?

A3: Pure water jets generally have lower operating costs since they don’t require abrasive materials, whereas abrasive water jets involve expenses for abrasives and more frequent part replacements due to wear and tear.

Q4: What safety precautions are necessary when using any type of water jet?

A4: Essential safety measures include wearing protective equipment like goggles and gloves, ensuring proper training for operators, conducting regular pressure checks, and maintaining a clear workspace to prevent accidents from high-pressure streams.

Q5: Are water jets environmentally friendly compared to other cutting methods?

A5: Yes, most types of water jets are considered environmentally friendly because they use water as the primary medium, produce no hazardous fumes, and can be designed with water recycling systems to minimize waste and consumption.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read