Top Waterjet Cutting Machines Manufacturers for Frozen Foods: Precision Meets Sub-Zero Challenges

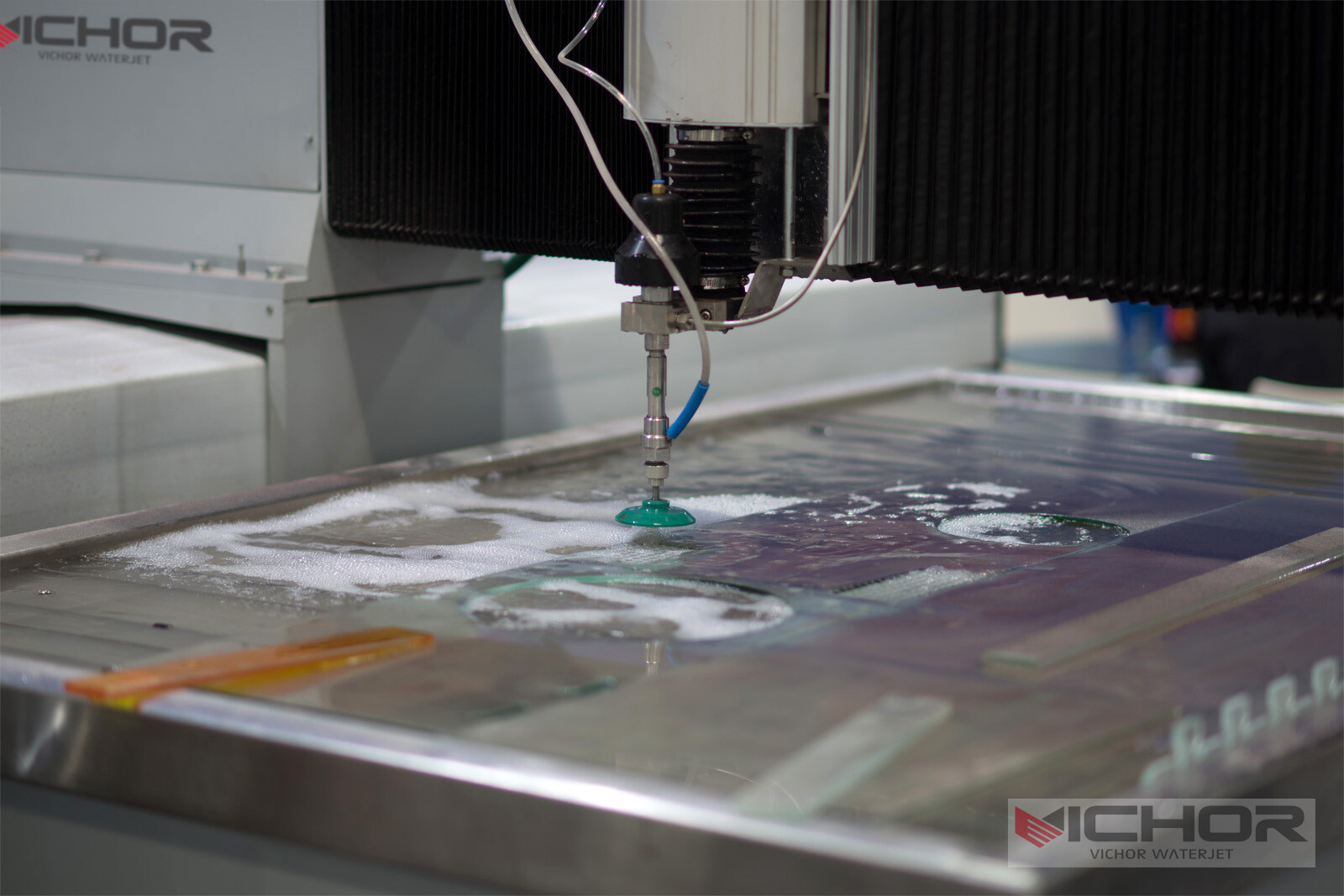

The frozen food industry demands precision, hygiene, speed, and minimal waste. Traditional cutting methods often struggle with frozen products, causing crumbling, excessive waste, temperature rise, and hygiene concerns. Enter waterjet cutting machines manufacturers for frozen foods. These specialized manufacturers design systems that harness the power of ultra-high-pressure water (often mixed with abrasives for tougher items) to deliver clean, accurate, and temperature-stable cuts directly on frozen or deep-frozen products. This technology has revolutionized processing lines for items ranging from IQF vegetables and frozen fruits to blocks of meat, poultry, fish, cheese, and even frozen desserts. This article delves into the critical aspects of selecting and working with waterjet cutting machines manufacturers for frozen foods.

Why Frozen Food Producers Choose Specialized Waterjet Cutting Machines Manufacturers

Not all waterjet systems are created equal, especially in the harsh, hygienic-critical environment of frozen food processing. Generic waterjet cutting machines manufacturers might offer standard systems, but those designed specifically for frozen foods incorporate crucial features:

Sub-Zero Compatibility: Components are engineered to withstand constant exposure to freezing temperatures without failure or performance degradation. Seals, hoses, pumps, and motion systems are selected or modified for cold environments.

Hygienic Design (EHEDG/3-A Compliance): Surfaces are smooth, crevice-free, and made from high-grade stainless steel (e.g., 316L). Designs minimize areas where water, food particles, or bacteria can accumulate, facilitating easy and effective cleaning (CIP/SIP compatibility is often available). This is paramount for food safety.

Temperature Control: The cutting process itself generates minimal heat (cold cutting process), preventing thawing or cooking at the cut edges. This preserves product integrity, texture, and weight (no moisture loss from melting).

Precision Cutting: Waterjets produce intricate shapes and consistent portions with minimal kerf (material removed by the cut), maximizing yield from expensive raw materials. This is crucial for portion control and premium product presentation.

Versatility & Speed: One machine can handle a vast array of products (soft fruits, hard root vegetables, dense meat blocks, delicate pastries) without tool changes, simply by adjusting pressure and abrasive flow. Modern systems offer high cutting speeds suitable for production lines.

Reduced Waste & Downtime: Precise cutting minimizes product loss compared to saws or blades. Minimal product contact and hygienic design reduce cleaning time and associated downtime.

Key Considerations When Choosing Waterjet Cutting Machines Manufacturers for Frozen Foods

Selecting the right partner is critical. Here are the essential factors to evaluate:

Core Expertise in Frozen Food Applications:

Look for waterjet cutting machines manufacturers for frozen foods with a demonstrable track record. Do they have case studies, testimonials, or references specifically from frozen food processors?

Do they understand the unique challenges of cutting IQF items, frozen blocks, or delicate frozen structures?

Can they provide application testing for your specific products? Reputable manufacturers often offer cutting trials to prove performance.

Hygienic Engineering & Certification:

Design Standards: Ensure the manufacturer adheres to recognized hygienic design standards like EHEDG (European Hygienic Engineering & Design Group) and/or 3-A Sanitary Standards. This isn’t optional; it’s a requirement.

Materials: All food-contact surfaces must be high-grade stainless steel (typically 316L). Verify the materials used for tanks, cutting heads, conveyors (if integrated), and guarding.

Cleanability: Examine how easy the machine is to disassemble (if needed) and clean. Are there dead spaces, sharp corners, or poorly welded joints? Look for fully drainable designs and smooth, radiused corners.

CIP/SIP Capability: Increasingly, leading waterjet cutting machines manufacturers for frozen foods offer integrated Clean-in-Place (CIP) and potentially Sterilize-in-Place (SIP) systems, drastically reducing manual cleaning labor and downtime.

Robustness & Cold Environment Performance:

Component Selection: Pumps, valves, intensifiers, high-pressure tubing, and seals must be specifically rated for continuous operation in freezing or near-freezing temperatures. Standard industrial components will fail prematurely.

Thermal Management: How does the manufacturer prevent freezing within the water delivery system itself? Look for features like trace heating on critical lines or pump enclosures with temperature control.

Structural Integrity: The frame and motion systems must resist thermal contraction/expansion without misalignment and withstand the humid, potentially corrosive washdown environment.

Cutting Performance & Technology:

Pressure & Power: Higher pressure pumps (60,000 PSI / 4,100+ bar and above) offer faster cutting speeds and the ability to handle thicker or denser frozen products efficiently. Evaluate pump reliability and maintenance needs.

Abrasive Delivery System: For cutting meat blocks, dense vegetables, or frozen prepared meals, an abrasive (typically garnet) is mixed with the water jet. The system must deliver abrasive consistently and controllably. Look for precise metering and minimal abrasive consumption designs.

Pure Waterjet Capability: For softer items like IQF berries, fruits, or delicate pastries, pure waterjet (no abrasive) is essential to prevent damage. A versatile system handles both modes.

Accuracy & Repeatability: Precision is key for portion control and yield. Evaluate the manufacturer’s motion system (linear motors, servo drives), controller, and positioning accuracy specifications.

Software: User-friendly, powerful software for nesting parts, optimizing cuts for yield, controlling the cutting path, and integrating with production line data (MES/ERP) is vital. Look for features specific to food processing.

Automation Integration & Scalability:

Line Integration: How easily does the waterjet integrate with upstream (freezing tunnels, weighing) and downstream (packaging, freezing) equipment? Look for manufacturers experienced in designing systems for inline frozen food processing.

Material Handling: Options range from manual loading to fully automated systems with robotic loading/unloading, vision systems for product orientation, and conveyor integration. Choose based on your production volume and labor strategy.

Scalability: Can the manufacturer provide solutions from pilot-scale machines to high-volume, multi-head production systems? Ensure they can grow with your business.

Support, Service & Total Cost of Ownership (TCO):

Global Support Network: For multinational producers, ensure the manufacturer has a responsive service network in your regions. Downtime is extremely costly.

Training & Documentation: Comprehensive training for operators and maintenance staff is essential. Clear documentation (manuals, parts lists, wiring diagrams) is crucial.

Parts Availability: Verify the availability and delivery times for critical spare parts, especially those prone to wear (seals, nozzles, garnet feed lines).

TCO Analysis: Look beyond the initial purchase price. Factor in consumables (garnet, nozzles, seals), energy consumption (high-pressure pumps are significant users), maintenance costs, expected yield improvements, and reduced labor/waste costs. Reputable waterjet cutting machines manufacturers for frozen foods should help model this.

Leading Technologies and Differentiators Among Manufacturers

The market features established players and innovative newcomers. Key differentiators include:

Ultra-High Pressure Pumps: Manufacturers continuously push pressure limits (90,000 PSI+ systems exist) for faster cutting in dense frozen products.

Dynamic Waterjet® and XD Technology: Some manufacturers (like OMAX, a Flow Waterjet company) offer technologies that actively control the jet stream shape for improved accuracy and reduced taper, particularly beneficial for intricate cuts.

Advanced Abrasive Management: Systems that minimize garnet consumption, improve mixing efficiency, and reduce operating costs are a significant advantage.

Integrated Vision Systems: For automated lines, vision systems guide cutting paths based on the actual position and shape of irregular frozen products, maximizing yield.

Predictive Maintenance: Utilizing IoT sensors and software to monitor component health (pump pressure, seal wear) and predict failures before they cause unplanned downtime.

The Future of Waterjet Cutting in Frozen Foods

Innovation continues rapidly. Expect to see:

Increased Automation: More sophisticated robotics and AI-driven vision systems for fully autonomous cutting lines.

Enhanced Data Integration: Deeper connectivity with plant-wide MES/SCADA systems for real-time production monitoring, traceability, and optimization.

Sustainability Focus: Developments in garnet recycling/reuse, energy-efficient pumps, and water recycling systems.

Further Miniaturization & Flexibility: Smaller footprint machines and more adaptable systems for diverse product ranges within a single facility.

Hybrid Systems: Potential integration with other technologies (e.g., laser scoring for snap-off portions) for specific applications.

Partnering with the right waterjet cutting machines manufacturers for frozen foods is a strategic investment for processors seeking to enhance product quality, maximize yield, ensure food safety, improve efficiency, and reduce waste. The specialized engineering required for the frozen environment – encompassing robust cold-operation components, rigorous hygienic design, precision cutting technology, and seamless automation integration – sets these manufacturers apart. By carefully evaluating manufacturers based on their frozen food expertise, adherence to sanitary standards, technological capabilities, support infrastructure, and overall value proposition, frozen food producers can unlock the significant benefits of waterjet cutting technology. As demands for efficiency, sustainability, and product innovation grow, the role of advanced waterjet cutting machines manufacturers for frozen foods will only become more critical in shaping the future of frozen food processing. Thorough due diligence in selecting your manufacturing partner ensures a solution that delivers long-term operational excellence on the production floor.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read