The Best Water Jet: Critical Elements for Superior Cutting Efficiency

In the world of industrial cutting and precision machining, the best water jet stands out as a versatile and powerful tool. Utilizing high-pressure water streams, often mixed with abrasives, this technology enables clean, accurate cuts across a wide range of materials without generating heat-affected zones. Whether you’re in manufacturing, construction, or creative design, understanding what makes the best water jet essential can transform your operations. This article delves into the key aspects that define the best water jet, providing insights into its technology, benefits, and practical considerations. By the end, you’ll have a comprehensive view of why investing in the best water jet is a game-changer for efficiency and quality.

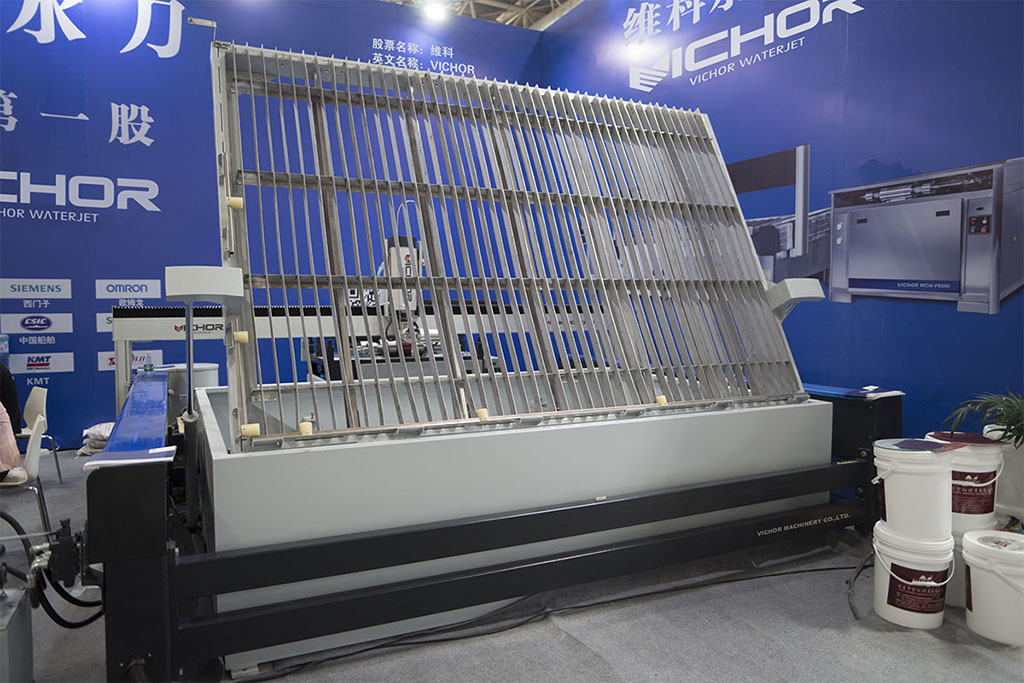

What Defines the Best Water Jet in Modern Applications

The best water jet is characterized by its ability to deliver consistent, high-performance cutting through advanced engineering. At its core, a water jet system uses pressurized water—sometimes enhanced with abrasive materials—to slice through various substances with remarkable precision. Unlike thermal cutting methods, the best water jet operates without heat, preventing material distortion and preserving the integrity of sensitive substrates. This makes it ideal for industries requiring intricate designs or working with heat-sensitive materials. Key defining factors include the pump pressure, cutting head design, and control systems, all of which contribute to what sets the best water jet apart from standard models. By focusing on these elements, users can achieve superior results in terms of speed, accuracy, and material versatility.

How the Best Water Jet Works: The Technology Behind the Power

Understanding the mechanics of the best water jet is crucial for appreciating its capabilities. The process begins with a high-pressure pump that intensifies water pressure to extreme levels, often exceeding 60,000 psi. This pressurized water is then directed through a narrow nozzle, creating a focused stream that can cut through materials like metal, stone, glass, and composites. In abrasive water jets, garnet or other abrasives are introduced into the stream to enhance cutting power for harder substances. The best water jet incorporates precision motion control systems, such as CNC technology, to guide the cutting path with minimal error. This combination of high pressure, abrasive integration, and automated control ensures that the best water jet delivers clean edges and complex shapes efficiently, reducing waste and improving productivity.

Advantages of Investing in the Best Water Jet

The best water jet offers numerous benefits that make it a preferred choice in various sectors. Firstly, its cold-cutting process eliminates heat-related damage, allowing for work on materials that are sensitive to high temperatures, such as plastics or certain metals. This also means no thermal stress or micro-cracking, which is common in laser or plasma cutting. Secondly, the best water jet is highly versatile, capable of handling a diverse array of materials without the need for tool changes. Additionally, it produces minimal kerf width and tight tolerances, ensuring high precision for detailed projects. Environmental advantages include reduced dust and fumes, as water suppresses particles during cutting. Overall, the best water jet enhances operational safety, reduces material waste, and supports sustainable practices.

Key Features to Look for in the Best Water Jet

When evaluating options, certain features distinguish the best water jet from average systems. High pump pressure and reliability are paramount, as they

directly impact cutting speed and capability. Look for systems with robust pumps that maintain consistent pressure over long periods. The cutting head design is another critical aspect; the best water jet often includes interchangeable nozzles and advanced abrasive delivery systems for optimized performance. Control software is equally important—user-friendly interfaces with CAD/CAM integration allow for seamless design execution and error reduction. Durability components, such as corrosion-resistant materials and easy maintenance access, ensure longevity. Finally, safety features like emergency stops and pressure monitoring make the best water jet a secure investment for any workspace.

Applications of the Best Water Jet Across Industries

The best water jet finds applications in a multitude of industries due to its adaptability and precision. In aerospace, it is used for cutting composite materials and titanium parts without compromising structural integrity. The automotive sector relies on the best water jet for shaping gaskets, interiors, and custom components. In architecture and art, it enables intricate designs on stone, glass, and metals for decorative elements. Manufacturing plants utilize the best water jet for prototyping and production runs, thanks to its ability to handle various thicknesses and materials. Even the food industry employs water jets for cutting products like pastries or frozen foods hygienically. This widespread use underscores why the best water jet is a valuable asset for innovation and efficiency.

Maintenance Tips for Prolonging the Life of the Best Water Jet

Proper maintenance is essential to keep the best water jet operating at peak performance. Regular inspection of the high-pressure pump for leaks or wear can prevent costly downtime. Cleaning the nozzles and filters frequently ensures consistent water flow and cutting quality. For abrasive systems, checking the abrasive delivery mechanism and replacing worn parts helps maintain efficiency. It’s also important to monitor water quality, as impurities can damage components; using filtered water is recommended. Scheduling routine calibrations for the control system ensures accuracy over time. By following these practices, users can extend the lifespan of the best water jet and maximize their return on investment.

How to Choose the Best Water Jet for Your Needs

Selecting the best water jet involves assessing your specific requirements, such as material types, cut complexity, and production volume. Start by considering the maximum pressure and cutting speed needed for your applications—higher pressure often translates to faster cuts on thicker materials. Evaluate the machine’s footprint and installation requirements to ensure it fits your workspace. Software compatibility is key; the best water jet should integrate with your existing design tools for smooth operations. Budget considerations include not only the initial cost but also long-term expenses like maintenance and abrasive consumption. Reading reviews and seeking demonstrations can provide practical insights. Ultimately, the best water jet for you will balance performance, reliability, and cost-effectiveness to meet your unique demands.

In conclusion, the best water jet represents a pinnacle of cutting technology, offering unmatched precision, versatility, and efficiency. By focusing on its defining features, advantages, and applications, businesses and individuals can leverage this tool to enhance their projects and workflows. As technology advances, the best water jet continues to evolve, promising even greater capabilities in the future.

Frequently Asked Questions

Q1: What types of materials can the best water jet cut effectively?

A1: The best water jet can cut a wide range of materials, including metals like steel and aluminum, ceramics, glass, stone, plastics, composites, and even rubber, thanks to its adjustable pressure and abrasive options.

Q2: How does the best water jet compare to laser cutting in terms of precision?

A2: The best water jet often matches or exceeds laser cutting in precision for many materials, as it avoids heat distortion and can handle reflective or thick surfaces that lasers struggle with, while maintaining tight tolerances.

Q3: What safety measures should be taken when operating the best water jet?

A3: Safety measures include wearing protective gear, ensuring proper training, using emergency stop features, regularly inspecting for high-pressure leaks, and maintaining a clean work area to prevent accidents.

Q4: Can the best water jet be used for underwater cutting applications?

A4: Yes, the best water jet can be adapted for underwater use, such as in marine or demolition work, where it reduces noise and debris, though specialized equipment may be required for optimal performance.

Q5: How often should maintenance be performed on the best water jet to ensure longevity?

A5: Regular maintenance should be done based on usage, but generally, daily checks for cleanliness and weekly inspections of pumps and nozzles are recommended, with comprehensive servicing every few months or as per manufacturer guidelines.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read