The 5 Key Factors That Truly Determine Your Water Jet Marble Cutting Machine Price

Investing in a water jet cutter is a pivotal decision for any stone fabricator, artisan, or large-scale operation working with marble. The precision, versatility, and cold-cutting ability of this technology are unmatched. However, the most pressing question for anyone considering this investment is invariably: What determines the final water jet marble cutting machine price?

The answer is rarely a simple figure. The water jet marble cutting machine price is a composite of various technical specifications, build qualities, and operational considerations. Understanding these factors is crucial to making an informed purchase that aligns with your production needs, workshop capabilities, and long-term budget. This in-depth guide will dissect the five primary elements that shape the cost, empowering you to navigate the market and find the machine that offers the best value for your specific requirements.

1. The Heart of the Machine: Pump Type and Power Pressure

The pump is the undeniable core of the system, generating the immense pressure needed to cut through hard materials like marble. The type and capability of the pump are the most significant factors influencing the water jet marble cutting machine price.

There are two main types of pumps:

Intensifier Pumps: These pumps use hydraulic power to amplify water pressure. They are renowned for generating extremely high and consistent pressure levels, often reaching up to 90,000 PSI (6,200 bar) or more. This results in superior cut quality, faster cutting speeds on thick materials, and exceptional reliability. However, this high performance and complex engineering come at a premium, making them a major driver of a higher water jet marble cutting machine price.

Direct-Drive or Crankshaft Pumps: These pumps operate using a simpler, more straightforward mechanical action. They are generally more energy-efficient and have a significantly lower initial purchase cost. The trade-off is a lower maximum pressure output, typically capping around 60,000 PSI (4,100 bar). This can lead to slightly slower cutting speeds, especially on dense stone slabs over 2 inches thick.

Impact on Price: The choice between these pump technologies creates a wide cost variance. A machine equipped with a high-pressure intensifier pump will command a much higher price than a comparable model with a direct-drive pump. Furthermore, within each category, horsepower (HP) rating also affects cost; a 100HP pump will be more expensive than a 50HP model due to its greater output and capacity for productivity.

2. Size and Work Envelope: The Cutting Bed Dimensions

The physical size of the machine, specifically its cutting table or work envelope, is a very straightforward yet massive contributor to the overall water jet marble cutting machine price. Simply put, larger machines cost more money to build and therefore cost more to purchase.

Small-Format Tables (e.g., 4′ x 4′ or 1.2m x 1.2m): Ideal for small workshops, artists creating intricate marble inlays, or businesses focusing on tiles and smaller pieces. These compact systems represent the most accessible entry point with the lowest price tag.

Medium-Format Tables (e.g., 5′ x 10′ or 1.5m x 3m): This is the industry standard for most countertop fabrication shops. It efficiently handles the majority of standard marble slab sizes with minimal waste. This size offers the best balance between practical utility and water jet marble cutting machine price, making it the most popular choice.

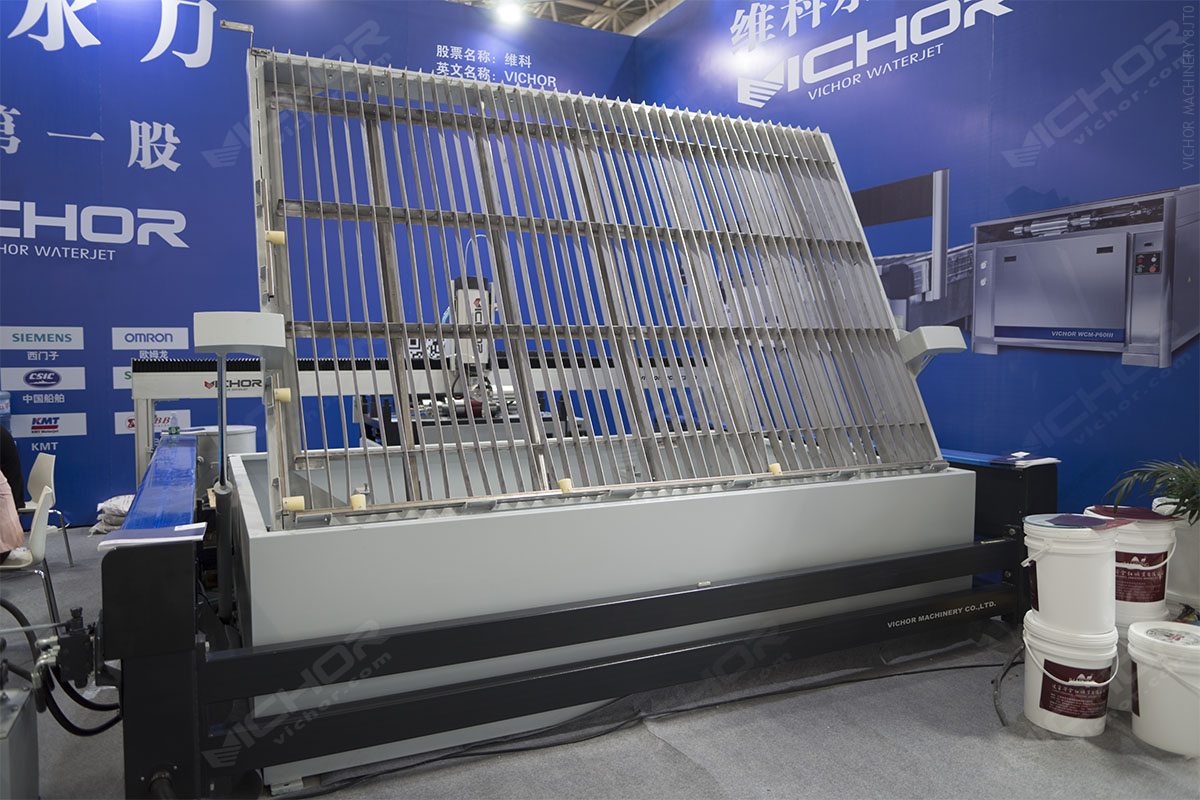

Large-Format and Gantry Systems (e.g., 10′ x 20′ or 3m x 6m and up): These are designed for high-volume industrial production. They can process multiple slabs simultaneously or handle enormous architectural pieces for large projects. The increased structural steel, larger motors, longer rails, and more complex control systems required result in a substantially higher investment.

3. Machine Construction and Component Quality

Not all water jets are built the same. The quality of materials and components used in the construction directly impacts the machine’s durability, precision, longevity, and ultimately, its water jet marble cutting machine price.

Key areas where quality varies include:

Frame and Structure: A machine built with a welded steel frame and stress-relieved construction will resist vibration and maintain accuracy over years of use far better than a lighter, bolted-together alternative. This robustness adds to the cost.

Motion System: The precision and speed of the cutting head are governed by its drive system. Machines using high-quality precision ground linear guides, heavy-duty servo motors, and industrial-grade gearboxes will provide smoother motion, faster acceleration, and better cut quality than those using lower-spec components. This higher performance level is reflected in the price.

Cutting Head and Nozzle: The quality of the cutting head, the durability of the mixing tube, and the type of orifice (e.g., sapphire vs. diamond) affect cut consistency, abrasive consumption, and maintenance frequency. Higher-end systems often feature more advanced and durable designs.

A lower initial water jet marble cutting machine price might be achieved by compromising on these components, but this can lead to higher long-term costs through more frequent repairs, greater downtime, and less consistent results.

4. Control Software and Automation Features

The water jet pump and table are powerful tools, but they are directed by the computer numerical control (CNC) software. The sophistication of this software is a critical part of the system’s value and a key factor in the water jet marble cutting machine price.

Basic Software: Entry-level systems may include software that handles simple CAD file import and basic cutting paths.

Advanced Software Suites: Higher-priced machines are bundled with powerful, intuitive software that dramatically enhances productivity. Key features that add value include:

Automatic Nesting: Optimizes the placement of parts on a slab to minimize material waste, a crucial saving when working with expensive marble.

Kerf Compensation: Automatically adjusts the cutting path to account for the width of the jet, ensuring part dimensions are accurate.

Collision Avoidance: Prevents the cutting head from crashing into the material or the table.

Cut Path Optimization: Orders the cutting sequence for maximum efficiency and speed.

The development and integration of this advanced software represent significant engineering investment, which is factored into the water jet marble cutting machine price.

5. Operating Costs and Total Cost of Ownership (TCO)

A truly comprehensive understanding of the water jet marble cutting machine price must look beyond the initial purchase invoice. The Total Cost of Ownership (TCO) includes all ongoing expenses, and some machines are designed to be more efficient than others.

Abrasive Garnet: This is the largest recurring consumable cost. Consumption rates can vary based on pump pressure and cutting head efficiency. A machine that uses abrasive more effectively can lead to substantial annual savings.

Energy Consumption: High-pressure pumps are significant users of electricity. More energy-efficient pump designs can reduce monthly operational expenses.

Replacement Parts: Wear items like high-pressure seals, orifice jewels, and mixing tubes need regular replacement. The cost, availability, and lifespan of these parts differ between machines.

Water: While not a major cost, water usage and the system for filtering and recycling it (if equipped) are small factors.

Maintenance and Downtime: A reliable machine from a manufacturer with strong technical support minimizes costly production interruptions. The potential cost of downtime is a hidden but critical part of the TCO equation.

A machine with a slightly higher initial water jet marble cutting machine price but significantly lower operating costs and higher reliability will often provide a much better return on investment over a five-to-ten-year period.

The water jet marble cutting machine price is a spectrum, typically ranging from approximately $70,000 for a basic, small-format system to well over $500,000 for a fully-equipped, large-format, production-grade machine. The final cost for your operation will depend on where your needs fall within the five factors outlined above.

The key to a successful purchase is to shift the focus from merely finding the lowest price to seeking the highest value. Carefully evaluate your current and projected workflow: the typical slab sizes you handle, your required production volume, and the level of precision your clients demand. By thoroughly understanding what drives the water jet marble cutting machine price, you can make a strategic investment that boosts your capabilities, enhances your product quality, and maximizes your profitability for years to come.

continue reading

Related Posts

- 1103 words5.6 min read

- 1111 words5.6 min read