The 3 Facts You Need to Know About Mini Waterjet Cutters for Small Shops

The world of precision cutting isn’t just for massive factories anymore. A mini waterjet cutter is changing the game for workshops, labs, and small manufacturers. This compact technology brings the power of waterjet cutting to a desktop or small-floor footprint.

It promises the same cold-cutting benefits—no heat distortion, no toxic fumes—but in a smaller, more affordable package. But is a small waterjet cutter right for your operation?

Let’s look beyond the hype and examine how these compact systems work, where they excel, and what you really need to consider.

How a Compact Waterjet System Operates

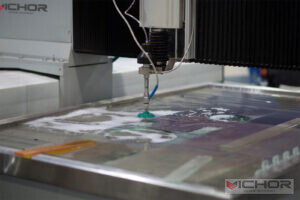

The core principle is identical to its industrial cousins. A high-pressure pump intensifies water. This water is forced through a tiny orifice to create an ultra-focused, supersonic stream.

For cutting harder materials, an abrasive garnet is introduced into this stream. In a mini abrasive water jet cutter, this mixing happens in a compact cutting head.

The key difference is scale. The pump, the abrasive delivery system, and the motion frame are all miniaturized. The tank is smaller. The working area, or cutting bed, is typically measured in just a few square feet.

This reduction in size and component power is what drives down the cost and complexity, making the desktop waterjet cutter a reality.

Primary Applications for a Small Waterjet Machine

Who uses a mini waterjet? The user base is surprisingly broad.

Prototyping labs and R&D departments love them. They can test cuts on exotic materials like titanium, carbon fiber, or brittle ceramics without investing in a full-scale machine. Small fabrication shops use them for custom metal parts, intricate signs, or specialized tools.

Artists and designers utilize a tabletop waterjet cutter for detailed work in stone, glass, and metals for jewelry or sculpture. Educational institutions, from universities to technical colleges, use them as training tools.

Even larger companies sometimes deploy a mini waterjet cutter as a secondary system for small, quick jobs, freeing up their main production machine.

Key Functions and Limitations

The main function is precise, cold cutting of complex shapes in a wide material range. A mini waterjet cutter delivers on the core promise of the technology: versatility without thermal damage.

Its compact size is its greatest advantage for space-constrained environments. Operational costs for power and water are lower. The learning curve can be gentler due to simpler software and setup.

However, limitations exist. Cutting thickness is the most significant. While a large industrial machine can slice through 8+ inches of steel, a small waterjet cutter typically maxes out at 1-2 inches for soft materials and less for harder metals.

Cutting speed is also slower at comparable thicknesses due to lower pump pressure. The abrasive capacity is smaller, requiring more frequent refills on long jobs.

Types and Configurations of Mini Systems

Not all compact systems are the same. The first major split is between pure water and abrasive-capable models.

A pure water desktop cutter is for soft materials only—rubber, foam, gaskets, food, and thin plastics. These are the simplest and most affordable.

For metal, stone, or glass, you need an abrasive mini waterjet cutter. These incorporate a miniaturized abrasive delivery system. They are more complex and costly but vastly more useful.

Configurations also vary. Some are fully integrated, all-in-one units. Others are modular, where a small pump can be paired with different cutting tables. Motion systems range from simple 2-axis frames to more sophisticated 3-axis setups for contouring.

Price Analysis: Cost vs. Value for Money

The price of a mini waterjet cutter is its most attractive feature compared to industrial systems. Entry-level pure water models can start in the tens of thousands of dollars.

A capable abrasive mini waterjet system typically ranges from the mid $50,000s to well over $100,000. This depends heavily on work area size, pump pressure (e.g., 40,000 PSI vs. 60,000 PSI), and automation features.

The true cost includes consumables: abrasive garnet, orifices, and mixing tubes. For a small business, the value lies in capability expansion. It allows you to take on jobs impossible with a laser or router, potentially opening new revenue streams.

For many, the calculation isn’t just machine price, but the opportunity cost of not having waterjet capability.

Service and Support Considerations

Buying a compact machine doesn’t mean you can overlook service. Downtime is costly at any scale. Understanding the supplier’s support network is critical.

Look for providers that offer clear warranties, accessible technical support, and readily available spare parts. Some suppliers specialize in these smaller systems and provide excellent, tailored support.

For companies that need results without the investment or operational burden, partnering with a service remains an option. A professional like VICHOR, known for large-scale industrial cutting, can handle high-volume or ultra-thick parts that exceed a mini cutter’s capacity.

This hybrid approach—using an in-house mini waterjet for quick prototypes and small batches, while outsourcing heavy-duty production—is a smart solution for many growing businesses.

Is a Mini Waterjet Cutter Your Right Solution?

Making the decision requires honest assessment. Start with your materials and thicknesses. If you primarily need to cut 1/2-inch aluminum or 3/4-inch stone with intricate details, a mini waterjet could be perfect.

If your daily work involves 2-inch steel plate, you’ll quickly hit its limits. Consider your workflow. Is it for prototyping, low-volume production, or education? These are ideal use cases.

Also, factor in your shop’s infrastructure. While smaller, these machines still need adequate electrical supply, a drain, and a method for handling wet abrasive sludge.

For those who need both small-scale flexibility and large-scale power, developing a relationship with an industrial provider like VICHOR ensures you have access to full-scale waterjet cutting solutions when your project demands it.

Frequently Asked Questions (FAQ)

Q1: What is the typical cutting tolerance of a mini waterjet cutter?

A1: A well-calibrated mini waterjet cutter can achieve tolerances around +/- 0.005 inches (0.127 mm). This is suitable for most prototyping and light fabrication work. Tighter tolerances are possible but may require slower cutting speeds and optimal material condition.

Q2: Can I cut tempered glass with a mini waterjet?

A2: No, you cannot. Like all waterjets, a mini waterjet cutter will cause tempered glass to shatter into small pieces upon penetration. It is excellent for cutting annealed (non-tempered) glass, ceramic, and stone, but tempered glass must be cut before the tempering process.

Q3: How messy is it to operate one in a small shop?

A3: It is a wet process, so some mess is inherent. However, modern desktop waterjet cutter models are designed with containment in mind. They feature enclosed cutting chambers, integrated water tanks, and systems to manage the abrasive slurry. Proper setup and maintenance keep the workspace clean.

Q4: What materials are most challenging for a small machine?

A4: Very thick, dense materials like thick tool steel or tungsten carbide will challenge a mini waterjet’s capacity. They require extremely slow cutting speeds and may exceed the machine’s pressure or abrasive delivery capability, leading to poor edge quality or inability to pierce.

Q5: How does the operating cost compare to a laser cutter?

A5: The initial machine cost for a mini waterjet is often higher than a laser of similar work area. However, operating costs differ. Lasers have high power consumption and gas costs. Waterjets continuously consume abrasive garnet and have wear parts (orifices, nozzles). The waterjet’s advantage is material versatility—it cuts what lasers can’t (reflective, heat-sensitive, or thick materials) without additional cost per material type.

continue reading

Related Posts

- 1281 words6.5 min read