Pressurized Water Cutting Metal: How It Works, Benefits, and Common Issues

When it comes to precision cutting in industrial applications, pressurized water cutting metal has emerged as a game-changing technology. This method, often referred to as water jet cutting, uses high-pressure water streams to slice through metal with incredible accuracy. Unlike traditional cutting techniques that involve heat or mechanical force, pressurized water cutting metal offers a cold-cutting process that minimizes material distortion and thermal damage. As industries seek more efficient and eco-friendly solutions, understanding the ins and outs of pressurized water cutting metal becomes crucial. In this article, we’ll dive deep into how this process works, its key advantages, applications, common problems, and maintenance considerations. By the end, you’ll have a solid grasp of why pressurized water cutting metal is a preferred choice in many sectors.

What is Pressurized Water Cutting Metal?

Pressurized water cutting metal is a manufacturing process that employs a high-velocity stream of water, typically pressurized to levels exceeding 60,000 psi (pounds per square inch), to cut through various metals. This technique can be purely water-based for softer materials or combined with abrasive substances like garnet for harder metals. The core idea behind pressurized water cutting metal is to use the kinetic energy of water to erode and separate metal surfaces without generating heat. This makes it ideal for materials sensitive to high temperatures, such as aluminum, titanium, or stainless steel. The process is highly versatile, allowing for intricate designs and tight tolerances, which is why it’s widely used in aerospace, automotive, and construction industries. Moreover, pressurized water cutting metal is environmentally friendly, as it produces no hazardous fumes or waste, aligning with modern sustainability goals. By leveraging this method, manufacturers achieve clean edges and reduced material waste, enhancing overall efficiency.

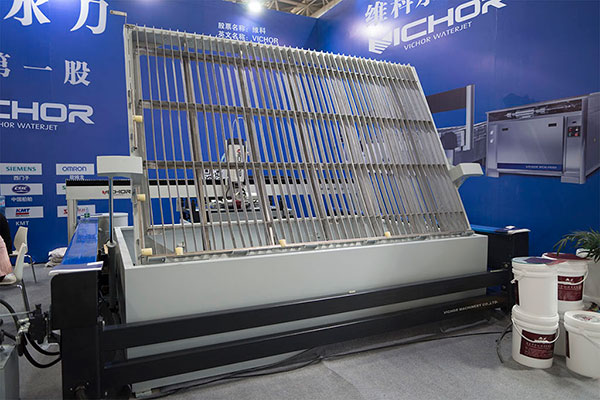

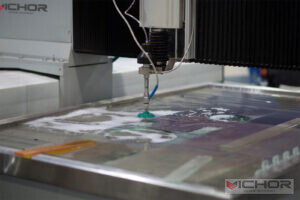

How Does Pressurized Water Cutting Metal Work?

The mechanics of pressurized water cutting metal involve several key components: a high-pressure pump, a cutting head, and a water delivery system. First, water is pressurized using an intensifier pump or direct drive system, which amplifies the water pressure to extreme levels. This pressurized water is then forced through a small nozzle, often made of diamond or sapphire, to create a focused jet stream. In cases involving harder metals, abrasives are mixed into the stream to enhance cutting power. The nozzle moves along a pre-programmed path, guided by computer numerical control (CNC), to execute precise cuts. The entire process of pressurized water cutting metal relies on the principle of erosion, where the high-speed water particles wear away the metal surface. This results in a smooth, burr-free edge without heat-affected zones. One of the standout features of pressurized water cutting metal is its ability to handle complex geometries and thick materials, often up to several inches thick. This versatility stems from the adjustable pressure and abrasive flow, making it adaptable to different metal types and thicknesses. Overall, the efficiency of pressurized water cutting metal lies in its simplicity and precision, driven by advanced control systems.

Key Advantages of Using Pressurized Water Cutting for Metal

Pressurized water cutting metal offers numerous benefits that set it apart from traditional methods like laser or plasma cutting. Firstly, it is a cold-cutting process, meaning it doesn’t generate heat during operation. This prevents thermal distortion, hardening, or micro-cracking in metals, preserving the material’s structural integrity. Secondly, pressurized water cutting metal is highly versatile—it can cut a wide range of metals, from soft copper to hard alloys, without requiring tool changes. This reduces downtime and increases productivity. Another advantage is the environmental friendliness of pressurized water cutting metal; it uses water and natural abrasives, producing minimal waste and no toxic emissions. Additionally, the process allows for high precision and intricate detailing, making it suitable for industries like jewelry or medical device manufacturing. The lack of mechanical force also means reduced stress on the material, leading to longer tool life and lower maintenance costs. Economically, pressurized water cutting metal can be cost-effective for small batches or prototypes due to its minimal setup time. Lastly, safety is enhanced as there’s no risk of fire or sparks, which is critical in hazardous environments. These advantages make pressurized water cutting metal a reliable and efficient choice for modern manufacturing.

Applications of Pressurized Water Cutting in Metalworking

Pressurized water cutting metal finds applications across diverse industries due to its adaptability and precision. In the aerospace sector, it’s used to cut lightweight metals like titanium and aluminum for aircraft components, where accuracy and lack of heat damage are paramount. The automotive industry employs pressurized water cutting metal for fabricating parts such as engine components, body panels, and custom fittings, thanks to its ability to handle various thicknesses and materials. In construction, this method is ideal for cutting structural steel, rebar, and metal plates for buildings and infrastructure projects.  The art and design field also benefits from pressurized water cutting metal, as it enables the creation of intricate metal sculptures and decorative elements with fine details. Moreover, the electronics industry uses it for precise cutting of metal casings and components without inducing electrical damage. Another growing application is in the renewable energy sector, where pressurized water cutting metal is used to produce parts for wind turbines and solar panels. The medical field leverages this technology for manufacturing surgical instruments and implants, ensuring sterile, burr-free edges. Overall, the versatility of pressurized water cutting metal makes it a go-to solution for any scenario requiring high-quality metal cutting without compromises.

The art and design field also benefits from pressurized water cutting metal, as it enables the creation of intricate metal sculptures and decorative elements with fine details. Moreover, the electronics industry uses it for precise cutting of metal casings and components without inducing electrical damage. Another growing application is in the renewable energy sector, where pressurized water cutting metal is used to produce parts for wind turbines and solar panels. The medical field leverages this technology for manufacturing surgical instruments and implants, ensuring sterile, burr-free edges. Overall, the versatility of pressurized water cutting metal makes it a go-to solution for any scenario requiring high-quality metal cutting without compromises.

Common Problems and Solutions in Pressurized Water Cutting Metal

Despite its benefits, pressurized water cutting metal can encounter issues that affect performance. One common problem is nozzle wear, which occurs due to the high-pressure flow and abrasive particles. This can lead to reduced cutting speed and accuracy. To mitigate this, regular inspection and replacement of nozzles are essential, using durable materials like diamond. Another issue is water quality; impurities in the water can clog the system or damage components. Using filtered or deionized water helps maintain efficiency in pressurized water cutting metal. Abrasive delivery problems, such as inconsistent flow or blockages, can also arise, causing uneven cuts. Ensuring proper abrasive storage and system calibration can prevent this. Pressure loss is another frequent challenge in pressurized water cutting metal, often due to pump issues or leaks. Routine maintenance of pumps and seals is crucial to sustain optimal pressure levels. Additionally, edge quality issues, like tapering or roughness, may occur if parameters are misadjusted. Optimizing feed rate, pressure, and abrasive mix can resolve this. Finally, safety hazards, such as high-pressure leaks or noise, require strict adherence to protocols, including protective gear and regular training. By addressing these problems proactively, users can maximize the lifespan and effectiveness of pressurized water cutting metal systems.

Maintenance Tips for Pressurized Water Cutting Systems

Proper maintenance is key to ensuring the longevity and efficiency of pressurized water cutting metal equipment. Start with daily checks: inspect hoses, fittings, and nozzles for wear or leaks, and clean the water filtration system to prevent contaminants. The high-pressure pump, the heart of the system, should undergo regular servicing, including seal replacements and pressure testing, to avoid breakdowns. For abrasive systems, monitor the hopper and delivery lines for clogs, and use high-quality abrasives to reduce wear. In pressurized water cutting metal, the cutting head often accumulates debris; a weekly cleaning routine with appropriate tools can prevent performance dips. Water quality management is vital—use soft or treated water to minimize scale buildup in the pump and lines. Additionally, calibrate the CNC controls periodically to maintain precision in cuts. Lubricate moving parts as per manufacturer guidelines to reduce friction and extend component life. Training operators on troubleshooting common issues, like pressure fluctuations or abrasive flow problems, can also enhance system uptime. By following these maintenance practices, businesses can avoid costly repairs and ensure consistent results with pressurized water cutting metal.

In summary, pressurized water cutting metal is a versatile, efficient, and environmentally friendly technology that revolutionizes metal fabrication. From its precise, heat-free cutting process to its wide-ranging applications and manageable challenges, it offers significant advantages over traditional methods. By understanding how pressurized water cutting metal works and implementing best practices for maintenance, industries can harness its full potential for improved productivity and quality. As technology advances, we can expect even more innovations in pressurized water cutting metal, making it an indispensable tool in the future of manufacturing. If you’re considering adopting this method, focus on training and regular upkeep to overcome common hurdles and reap the long-term benefits.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read