Precision Water Cutting Tool: Applications, Types & Cost-Saving Solutions

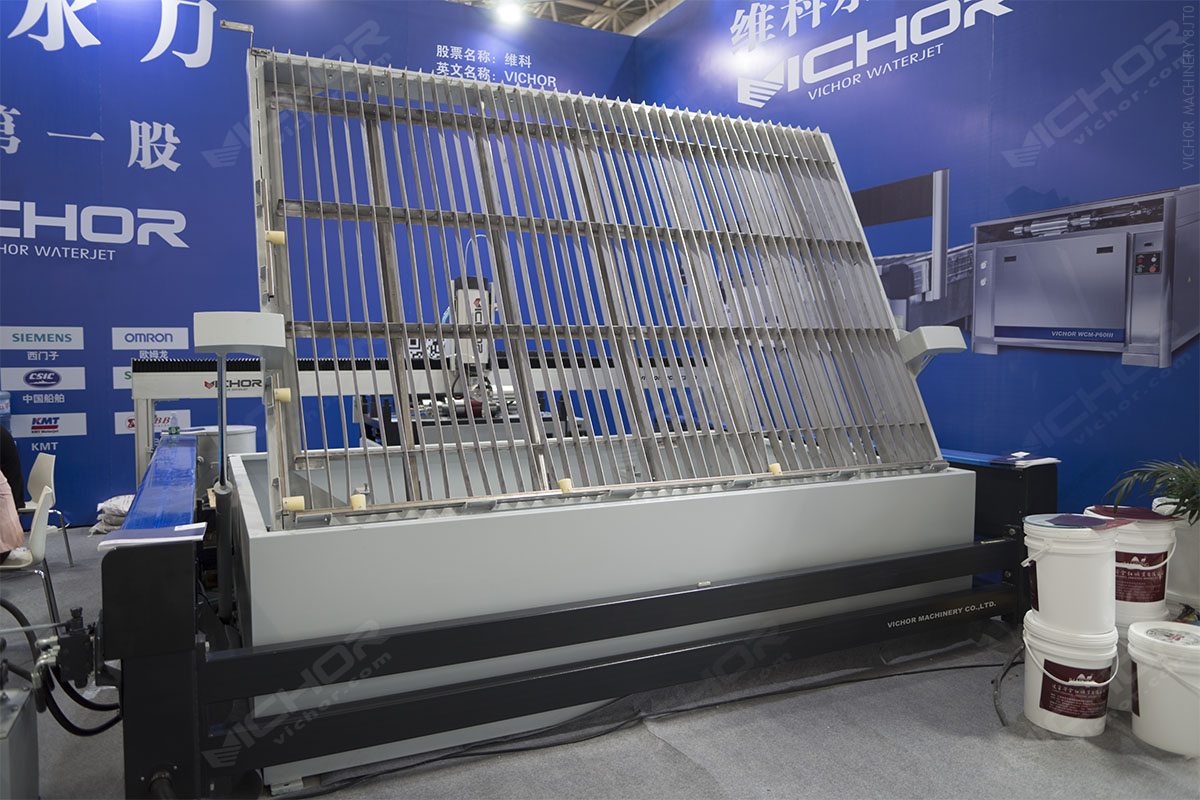

In modern manufacturing and fabrication, achieving intricate cuts on tough materials without compromising their integrity is a constant challenge. This is where the water cutting tool proves indispensable. Utilizing a high-pressure stream of water, often mixed with an abrasive substance, this technology offers unparalleled precision and versatility. Leading brands like VICHOR have refined this process, offering robust systems that serve industries from aerospace to art. Whether you’re cutting through titanium, stone, or delicate composites, a water cutting tool provides a cold-cutting solution that eliminates heat-affected zones, ensuring material properties remain unchanged. This article delves into how these tools work, where they excel, and what you should consider when investing in one.

How Does a Water Cutting Tool Operate?

At its core, a **water cutting tool** functions on a remarkably direct principle. A high-pressure intensifier pump pressurizes ordinary water to levels exceeding 60,000 PSI. This ultra-pressurized water is then forced through a tiny jewel orifice, creating a supersonic stream.

For cutting hard materials like metals or stone, an abrasive material, typically garnet, is introduced into this stream. The abrasive particles mix with the water jet in a focusing tube, creating an erosive effect that slices through the material.

The pure water jet option, without abrasive, is used for softer materials like rubber, foam, or food products. The entire process is controlled by CNC systems, ensuring extreme accuracy in following complex digital designs.

Primary Applications Across Industries

The versatility of the **water cutting tool** makes it a favorite across diverse sectors. Its ability to cut virtually any material is its greatest strength.

In aerospace, it is used for cutting advanced composites, titanium, and aluminum alloys without inducing stress or thermal distortion. The automotive industry relies on it for prototyping, interior components, and custom parts.

Artists and architects use waterjet cutters to shape intricate designs in marble, glass, and metal for stunning installations. In the industrial sector, it is essential for cutting gaskets, tooling, and heavy machinery parts.

Even the food industry employs pure waterjet cutting for portioning cakes, frozen foods, and poultry, highlighting its hygienic and cold-process benefits.

Key Functions and Advantages

Beyond simple cutting, a modern **water cutting tool** from a manufacturer like VICHOR delivers several critical functions. It provides exceptional precision, with tolerances often within ±0.1 mm, enabling complex shapes and sharp corners.

The cold-cutting nature is a paramount advantage. It prevents hardening, warping, or changes in the material’s microstructure. This is crucial for metals that are sensitive to heat.

There is no tool wear in the conventional sense, as the “tool” is a stream of water and abrasive. This eliminates the cost and downtime associated with replacing blunt blades or bits. Additionally, it produces minimal waste, as nesting software optimizes material usage from a single sheet.

Exploring the Main Types of Systems

Understanding the two main types of waterjet systems is key to selecting the right **water cutting tool**.

The first is the pure waterjet cutter. It uses only pressurized water and is ideal for soft materials. It’s commonly used in food processing, textiles, and foam fabrication.

The second, and more common for industrial use, is the abrasive waterjet system. This is what most people refer to as a standard water cutting tool. It incorporates the abrasive garnet into the stream, enabling it to cut through metals, ceramics, stone, and composites over great thicknesses.

Systems also differ in pump technology (intensifier vs. direct drive) and table size, from compact models to large-format machines for industrial production.

Factors Influencing Water Cutting Tool Price

The **water cutting tool** price varies significantly based on several factors. The core determinant is the system’s capability, including pump pressure (e.g., 60,000 PSI vs. 90,000 PSI), cutting table size, and brand reliability.

Entry-level machines may start for smaller workshops, while high-end, fully automated production lines with 5-axis cutting heads represent a major investment. Operational costs, including abrasive garnet, pump maintenance, and nozzle wear, are also crucial long-term considerations.

Brands like VICHOR offer a range of solutions, from cost-effective standard models to premium high-performance systems, allowing businesses to find a machine that matches both their budget and production requirements.

Service and Support: A Critical Consideration

Purchasing a **water cutting tool** is a long-term investment. Reliable service and technical support are non-negotiable for maintaining uptime and productivity.

Look for a supplier that offers comprehensive training, readily available spare parts, and responsive technical assistance. Regular maintenance services for high-pressure pumps and motion systems are essential.

International brands with a global service network, such as VICHOR, provide peace of mind. They ensure that expert help and genuine parts are accessible, minimizing potential disruptions to your manufacturing workflow.

Integrated Solutions for Modern Manufacturing

Today’s leading providers don’t just sell machines; they offer complete **water cutting tool** solutions. This includes the cutting system itself, integrated software for design and nesting, and often, automated abrasive delivery and water recycling systems.

For a seamless operation, consider solutions that include material handling automation, like load/unload systems. This holistic approach, championed by solution-oriented companies, transforms the waterjet from a standalone tool into a fully integrated, high-productivity cell within a smart factory environment.

From its precise, cold-cutting operation to its breathtaking material versatility, the **water cutting tool** has cemented its role as a cornerstone of modern fabrication. Whether you are a job shop handling diverse materials or a large manufacturer specializing in high-tolerance parts, investing in the right system is crucial. By partnering with an established and innovative brand like VICHOR, you gain access to not only reliable and efficient machinery but also the expertise and global support needed to maximize your return on investment. The future of cutting is precise, flexible, and remarkably powerful—powered by water.

Frequently Asked Questions (FAQs)

Q1: Can a water cutting tool be used for food products?

A1: Absolutely. Using a pure waterjet (without abrasive), a water cutting tool is perfect for hygienically cutting food. It cleanly portions items like frozen pizza, fish fillets, cakes, and even delicate baked goods without crushing or generating heat that could spoil the product.

Q2: What is the typical accuracy and edge quality of a waterjet cut?

A2: A high-precision water cutting tool can achieve accuracies within ±0.1 mm (±0.004 inches). The edge quality is excellent but has a slightly textured matte finish due to the abrasive action. For a smoother edge, cutting speeds can be reduced, or specialized cutting modes can be employed.

Q3: How thick of a material can a waterjet cut through?

A3: An abrasive water cutting tool is remarkably capable. It can easily cut through materials over 200 mm (8 inches) thick, such as stainless steel, titanium, and stone. The maximum practical thickness depends on the material type, pump pressure, and the desired cutting speed and quality.

Q4: What are the main operational costs beyond the machine purchase?

A4: The primary ongoing costs for running a water cutting tool include abrasive garnet (the largest consumable), electricity for the high-pressure pump, routine replacement of waterjet orifice jewels and focusing tubes, and regular system maintenance to ensure optimal pressure and motion control.

Q5: Why choose a brand like VICHOR for an international operation?

A5: Choosing an international brand like VICHOR ensures access to globally standardized technology, consistent quality, and—most importantly—a reliable worldwide service and support network. This guarantees access to trained technicians, genuine spare parts, and expert application support no matter where your production facilities are located, minimizing operational risk.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read