Precision CNC Water Jet Cutting Service: Your Ultimate Guide to Versatile Material Processing

In the demanding world of modern manufacturing, prototyping, and custom fabrication, achieving precise, complex cuts in a vast array of materials without compromising their inherent properties is paramount. This is where CNC Water Jet Cutting Service emerges as an indispensable, highly versatile solution. Combining the sheer force of ultra-high-pressure water with computer numerical control (CNC) precision, this technology offers unparalleled capabilities. This comprehensive guide delves deep into the world of CNC water jet cutting service, exploring its mechanics, advantages, applications, materials, and key considerations for selecting the right provider.

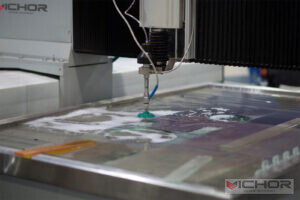

What is CNC Water Jet Cutting and How Does it Work?

At its core, a CNC water jet cutting service utilizes a high-pressure stream of water, often mixed with an abrasive garnet sand, to erode material with exceptional accuracy. The process is guided by sophisticated CNC software, which interprets digital design files (like CAD drawings) and precisely controls the movement of the cutting head along the X, Y, and sometimes Z axes. Here’s a breakdown of the process:

Ultra-High Pressure Generation: A high-pressure pump (typically intensifier or direct drive type) pressurizes ordinary tap water to extreme levels, often between 60,000 PSI (4,100 bar) and 90,000 PSI (6,200 bar) or even higher.

Stream Formation: The pressurized water is forced through a tiny orifice in a jewel (usually diamond or sapphire), creating a coherent, ultra-fast water stream moving at speeds approaching Mach 3.

Abrasive Introduction (For Hard Materials): For cutting metals, stone, glass, ceramics, and composites, an abrasive material (garnet is most common) is precisely metered into the water stream within a mixing chamber. The abrasive particles become entrained in the water jet, dramatically increasing its cutting power through erosion. Pure water jets (without abrasive) are used for softer materials like rubber, foam, gaskets, and food products.

Cutting Head & Nozzle: The abrasive-laden (or pure) stream then exits through a focusing tube (also called a nozzle or mixing tube), maintaining its coherence and directing the cutting energy onto the workpiece.

CNC Precision Control: The cutting head is mounted on a robust gantry system. The CNC controller meticulously follows the programmed toolpath, maneuvering the head over the material to cut intricate shapes, sharp corners, and complex geometries with tolerances often within +/- 0.005 inches (0.13 mm).

Cutting Action: The high-velocity stream impacts the material, eroding a very narrow path (kerf). The water also acts as a coolant, minimizing heat-related distortion and removing debris from the cut zone.

The result is a clean, precise cut with smooth edges, achieved without introducing heat or mechanical stresses into the material. This cold-cutting nature is a defining advantage of CNC water jet cutting service.

The Unmatched Versatility: Materials a CNC Water Jet Can Cut

One of the most compelling reasons to choose a CNC water jet cutting service is its astonishing material versatility. Unlike thermal processes (laser, plasma) or mechanical methods (sawing, milling), waterjet cutting is largely unaffected by a material’s hardness, reflectivity, or thermal conductivity. This opens the door to processing an incredibly diverse range of materials:

Metals: Stainless steel, aluminum, titanium, brass, copper, tool steel, armor plate, mild steel (thin to very thick sections – often several inches thick).

Stone & Tile: Granite, marble, slate, travertine, porcelain tile, ceramic tile, engineered stone.

Glass: Float glass, tempered glass (requires special techniques), laminated glass, mirrors, borosilicate glass.

Composites: Carbon fiber reinforced polymers (CFRP), fiberglass (GFRP), Kevlar, laminates, honeycomb structures (excellent for delamination-free cutting).

Plastics & Polymers: Acrylic (Plexiglas), polycarbonate, PVC, HDPE, UHMW, nylon, ABS, foam (various densities), rubber.

Exotic Materials: Tungsten, Inconel, Hastelloy, ceramics, stoneware.

Other Materials: Leather, textiles, gaskets, paper products, food (using pure water jet).

A proficient CNC water jet cutting service can seamlessly switch between cutting hardened tool steel one hour and delicate foam or intricate tile patterns the next, all on the same machine, using the same fundamental process. This flexibility is unmatched by any other single cutting technology.

Key Advantages of Choosing a CNC Water Jet Cutting Service

Why opt for CNC water jet cutting service over other fabrication methods? The benefits are numerous and significant:

Cold Cutting Process: Absolutely no Heat-Affected Zone (HAZ). This is critical for materials sensitive to heat, preventing warping, hardening, softening, or metallurgical changes at the cut edge. It also eliminates toxic fumes or vapors associated with melting processes.

Material Versatility: As detailed above, it cuts virtually anything, eliminating the need for multiple specialized machines.

Exceptional Precision and Edge Quality: CNC control ensures high accuracy and repeatability. Waterjet produces smooth edges with minimal burr, often requiring little to no secondary finishing. It excels at intricate details and sharp internal corners that are difficult or impossible with other methods.

No Mechanical Stresses: The cutting force is localized and minimal compared to mechanical methods like punching or shearing, preventing deformation or micro-cracking, especially in brittle materials like glass or ceramics.

Environmentally Friendly: Primarily uses water and natural garnet abrasive. The waste slurry (water, abrasive, and cut material particles) is inert and non-hazardous for most materials, making disposal simpler and more eco-friendly than many alternatives. Pure water cutting is exceptionally clean.

Thick Material Capability: Waterjets excel at cutting very thick materials (6 inches, 12 inches, or even more for softer materials) that would be slow, impractical, or impossible for lasers or plasma to handle effectively.

Minimal Kerf Width: The cutting stream is very narrow, resulting in less material waste, especially important for expensive materials. Kerf widths typically range from 0.030″ to 0.050″ (0.76mm to 1.27mm) depending on orifice/nozzle size and material thickness.

Ease of Programming & Setup: CAD/CAM software translates designs directly into machine paths. Setup typically involves simply placing the material on the cutting table and securing it, often with minimal fixturing required compared to milling.

Wide-Ranging Applications Across Industries

The unique capabilities of CNC water jet cutting service make it invaluable across a vast spectrum of industries. Here are some prominent examples:

Aerospace & Aviation: Cutting titanium components, aluminum structural parts, engine components, composites (fuselage panels, wings), high-strength alloys, insulation, and gaskets. The lack of HAZ is crucial for aerospace integrity.

Automotive: Prototyping parts, interior and exterior trim components (metal, plastic, fabric), gaskets, composite body panels, foam seating, filters, and specialized tooling.

Architecture & Construction: Creating intricate decorative metalwork (gates, railings, facades), precise stone and tile inlays, countertops (granite, quartz), signage (metal, acrylic), structural components, and artistic installations.

Manufacturing & Industrial Machinery: Fabricating machine parts, gears, flanges, brackets, tooling plates, wear plates, conveyor components, and prototypes from diverse metals and plastics.

Marine: Cutting hull components, decks, bulkheads from composites, stainless steel fittings, interior panels, gaskets, and insulation.

Art & Signage: Producing highly detailed sculptures, complex logos, dimensional letters, and decorative elements from materials like metal, stone, glass, acrylic, and wood.

Electronics: Cutting insulating materials, composite panels for enclosures, gaskets, and specialized components requiring no thermal distortion.

Food Industry (Pure Water Jet): Precisely cutting frozen foods, cakes, pastries, poultry, fish, and other products hygienically and without contamination.

Medical & Dental: Manufacturing surgical tools, implants (titanium), medical device components, orthopedic templates, and biocompatible plastic parts, all without thermal degradation.

The adaptability of CNC water jet cutting service ensures it remains a go-to solution for bespoke projects and high-volume production runs alike.

Selecting the Right CNC Water Jet Cutting Service Provider

Not all CNC water jet cutting service providers are created equal. Choosing the right partner is crucial for quality, timeliness, and cost-effectiveness. Consider these factors:

Experience & Expertise: Look for providers with a proven track record, particularly experience cutting materials and thicknesses relevant to your project. Ask about their team’s technical knowledge.

Machine Capability & Technology: Inquire about the size of their cutting tables (determines maximum part size), pump pressure (affects speed and thick material capability), and the sophistication of their CNC controls and software. Modern 5-axis heads add significant capability for beveling and complex 3D shapes.

Material Handling & Capacity: Ensure they can handle your specific material type, thickness, and sheet sizes. Do they offer material sourcing assistance?

Precision & Tolerances: Discuss the typical tolerances they hold and their quality control processes. Ask about their ability to achieve the edge finish you require. Viewing samples is advisable.

Lead Times & Capacity: Understand their standard turnaround times and whether they have the capacity to handle rush jobs if needed.

Design & Engineering Support: A good provider will offer support with CAD file preparation (DXF, DWG, STEP, etc.), nesting parts for optimal material utilization, and design for manufacturability (DFM) advice to optimize your part for waterjet cutting.

Secondary Services: Do they offer value-added services like deburring, finishing (sanding, polishing), forming, welding, or assembly? This can streamline your supply chain.

Communication & Customer Service: Responsiveness, clear communication, and proactive problem-solving are essential. Are they easy to get a quote from?

Pricing Structure: Understand how they quote – by time, by length of cut, or a combination? Ensure pricing is transparent and competitive. Beware of quotes significantly lower than others; quality might be compromised.

Facility & Location: While less critical with modern logistics, proximity can sometimes impact shipping costs and lead times. A clean, well-organized facility often reflects operational standards.

CNC water jet cutting service stands as a cornerstone technology in modern fabrication. Its unique combination of cold cutting, exceptional material versatility, high precision, and ability to handle complex geometries and thick sections makes it an irreplaceable solution for countless applications across diverse industries. From the delicate intricacies of aerospace composites to the rugged demands of thick steel plate, from the artistic flow of architectural stone to the hygienic needs of food processing, waterjet cutting delivers unparalleled results.

When seeking precision, material integrity, and flexibility, partnering with a skilled and well-equipped CNC water jet cutting service provider is not just an option; it’s often the optimal strategic choice. By understanding the technology’s capabilities and carefully selecting a provider based on the criteria outlined, businesses can unlock new design possibilities, improve part quality, reduce production costs through less waste and secondary operations, and ultimately gain a significant competitive edge in bringing their innovative ideas to life. The power of water, harnessed by computer precision, continues to redefine the boundaries of what’s possible in material processing.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read