Personal Water Jet Cutter: Your Compact Cutting Solution Explained

For decades, the incredible precision and material versatility of water jet cutting were confined to large, industrial factories. These massive machines required significant space, hefty investments (often exceeding $100,000), complex infrastructure, and specialized operators. But what if you could harness the power of high-pressure water and abrasive garnet right in your home workshop, garage, or small business? Enter the revolutionary personal water jet cutter. This burgeoning class of compact machines is democratizing access to one of the most versatile cutting technologies available. This comprehensive guide dives deep into the world of personal water jet cutters, exploring their capabilities, limitations, ideal applications, and what you need to know before bringing one into your workspace.

What Exactly is a Personal Water Jet Cutter?

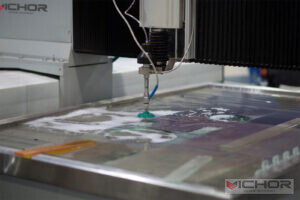

A personal water jet cutter is a scaled-down, more affordable, and user-friendly version of its industrial counterpart. At its core, it still utilizes the fundamental principle: generating an extremely high-pressure stream of water (often exceeding 50,000 PSI) and, for cutting harder materials, mixing that stream with fine abrasive garnet particles. This hyper-focused, high-velocity mixture erodes material with incredible precision, creating clean, detailed cuts without generating heat that can distort or damage the workpiece.

The key differentiators of a personal water jet cutter are:

Size: Significantly smaller footprint, often resembling a large benchtop CNC router or milling machine.

Cost: Dramatically lower price point, ranging roughly from $10,000 to $50,000+, compared to hundreds of thousands for industrial units.

Pressure: Typically operate at lower maximum pressures than industrial machines (often 40,000-60,000 PSI vs. 60,000-90,000+ PSI), impacting speed and maximum material thickness capabilities.

Infrastructure: Designed with simpler installation requirements. While they still need high-pressure pumps and water management, they often use smaller, self-contained intensifier pumps and require less robust plumbing and electrical connections than industrial models.

Target Audience: Geared towards makers, hobbyists, artists, small fabrication shops, R&D labs, prototyping studios, and educational institutions, rather than high-volume production facilities.

In essence, a personal water jet cutter brings the “cool cutting” power of water jet technology within reach for individuals and small businesses seeking unparalleled versatility without the industrial-scale commitment.

Unlocking Material Versatility: What Can You Cut?

This is arguably the most compelling feature of any water jet system, and personal water jet cutters deliver impressive versatility, albeit within certain thickness limitations compared to industrial machines. The cold-cutting process means no heat-affected zones, making them ideal for materials sensitive to thermal distortion.

Metals: Thin sheets of stainless steel, aluminum, brass, copper, titanium, and tool steel are readily cut. Thickness capabilities vary significantly by machine power and material hardness (e.g., 1/4″ aluminum might be feasible, while 1/4″ hardened tool steel might be very slow or exceed the machine’s capability). Expect slower speeds than dedicated metal-cutting methods like lasers or plasmas for thicker metals.

Plastics & Composites: Excels at cutting acrylic (Plexiglas), PVC, polycarbonate, HDPE, Delrin, fiberglass, carbon fiber composites (with care to minimize delamination), G10, and rubber. No melting, warping, or toxic fumes (like laser cutting PVC).

Stone, Tile & Glass: Ideal for intricate cuts in natural stone (marble, granite slate – thinner pieces), engineered stone (quartz), ceramic tile, porcelain tile, and glass (including laminated and tempered glass before the tempering process). The cold process prevents thermal shock cracking.

Foams & Insulation: Cuts rigid foams, insulation boards, and softer foams cleanly without crushing or melting edges.

Wood & Laminates: Capable of cutting plywood, MDF, solid woods (especially harder woods), and laminates. While not always the fastest method for wood, it allows for complex shapes without burning (like lasers) or tear-out (like routers).

Exotic Materials: Can handle materials that are difficult or dangerous to cut with other methods, such as Kevlar, certain ceramics, and layered materials.

Material Compatibility & Thickness Expectations for Personal Water Jet Cutters:

| Material Category | Examples | Thickness Range (Typical Personal Machine) | Key Advantages |

|---|---|---|---|

| Metals | Aluminum, Stainless Steel, Brass, Copper | 0.020″ – 0.25″ (0.5mm – 6mm) | No heat distortion, cuts reflective metals |

| Plastics | Acrylic, PVC, Polycarbonate, HDPE | Up to 1″ (25mm) or more | No melting, smooth edges, safe for PVC |

| Composites | Carbon Fiber, Fiberglass, G10 | Varies (0.125″ – 0.5″ / 3mm – 12mm common) | Clean cuts, minimizes delamination (with settings) |

| Stone & Tile | Marble, Granite, Ceramic, Porcelain | 0.25″ – 0.75″ (6mm – 20mm) | Cold process prevents cracking, intricate detail |

| Glass | Float Glass, Laminated (pre-tempered) | 0.125″ – 0.375″ (3mm – 10mm) | Chip-free edges, complex shapes possible |

| Wood & Laminate | Plywood, MDF, Hardwoods | Up to 1″ (25mm) or more | No burning, intricate designs, good for laminates |

| Foams & Insulation | XPS, EPS, PU Foams | Several Inches | Clean cuts, no crushing or melting |

Precision & Intricacy: The Detail Advantage

Personal water jet cutters inherit the core strength of water jet technology: exceptional precision and the ability to cut incredibly intricate details.

Tight Tolerances: Capable of holding tolerances typically in the range of +/- 0.005″ (0.127mm) or better, depending on machine calibration, setup, and material.

Complex Geometries: Effortlessly handles intricate designs, fine lettering, sharp inside corners, complex curves, and patterns that would be challenging or impossible with many other cutting methods (like routers or plasma cutters). CAD/CAM software drives the cutting path with high fidelity.

Minimal Kerf: The abrasive waterjet stream has a relatively small cutting width (“kerf”), usually between 0.03″ and 0.05″ (0.76mm – 1.27mm), minimizing material waste, especially important for expensive stock.

No Burrs or Mechanical Stress: The non-contact, cold-cutting process typically produces edges with minimal burrs (especially on metals and plastics) and induces no mechanical stress or heat distortion into the material. Edge finishing is often simplified compared to machined parts.

Scalpel-Like Cutting: Allows for features like very thin webs, delicate bridges, and fine details that might snap or break with mechanical cutting tools.

This precision makes personal water jet cutters ideal for detailed art pieces, intricate components for prototypes or models, custom jewelry, precision gaskets, and specialized parts requiring complex profiles.

Understanding the Limitations & Realistic Expectations

While powerful, personal water jet cutters are not industrial machines. Understanding their inherent limitations is crucial:

Cutting Speed: This is the most significant trade-off. Cutting speed is much slower than lasers for thin materials, plasma for thick metals, or routers for wood. Speed decreases dramatically as material thickness and hardness increase. Cutting 1/4″ aluminum might take minutes per foot, while 1/4″ titanium could take considerably longer. Patience is required.

Maximum Material Thickness: Limited by pump pressure and abrasive flow rate. While they can cut surprisingly thick soft materials (like foam or plastic), capabilities for hard metals and stone are generally restricted to thinner sections compared to industrial jets. Expect practical limits around 0.25″-0.5″ (6mm-12mm) for harder metals and 0.75″ (20mm) for stone on most personal machines.

Operating Costs:

Abrasive: Garnet sand is a significant consumable cost. While cheaper than industrial amounts, expect to budget for ongoing abrasive purchases.

Water: Requires filtered water. While the water itself is cheap, filtering and disposal/recycling of the abrasive slurry (water + spent garnet + cut material) require consideration and potentially add cost (slurry tanks, settling systems).

Nozzles & Components: High-wear parts like mixing tubes, focus nozzles, and high-pressure seals need periodic replacement.

Power: High-pressure pumps consume significant electricity during operation.

Noise & Vibration: While quieter than large routers or plasma cutters, the pump and cutting process generate noticeable noise and some vibration. Adequate space and hearing protection are recommended.

Mess & Containment: Cutting generates a spray of water, abrasive, and material particles. A fully enclosed cutting chamber is essential to contain the mess, protect the operator, and manage the slurry. This enclosure adds to the machine’s footprint.

Learning Curve: Requires learning CAD/CAM software for design and toolpath generation, understanding machine setup (abrasive feed, water pressure, cutting head height), and optimizing cutting parameters for different materials.

Maintenance: Requires regular maintenance – cleaning, replacing wear parts, checking filters, and ensuring the high-pressure system is functioning safely.

Setup, Operation & What You Really Need

Bringing a personal water jet cutter into your workspace isn’t as simple as plugging in a 3D printer. Consider these requirements:

Space: You need adequate floor space not just for the machine itself (including its enclosure and controller cabinet), but also for the high-pressure pump unit, a water supply/drain connection, and potentially a slurry collection tank or recycling system. Allow for maintenance access.

Power: Most personal water jet cutters require robust electrical service, typically 220V single-phase or 220V/3-phase, with sufficient amperage for the pump motor. Verify your shop’s electrical capacity.

Water Supply & Drain: Requires a clean water supply (often filtered) and a drain capable of handling the abrasive slurry. Slurry management is critical – options include settling tanks (requiring periodic cleaning), closed-loop recycling systems (higher upfront cost, less waste), or disposal via licensed haulers.

Compressed Air: Often needed for functions like abrasive feed control and purging lines.

Ventilation: While not emitting fumes like lasers, good general workshop ventilation is still beneficial.

Software: You’ll need compatible CAD software for design and CAM software specifically for generating water jet toolpaths. Some manufacturers offer integrated software packages.

Safety Gear: Safety glasses, hearing protection, and potentially waterproof aprons or boots are essential when accessing the machine during or after operation.

Material Handling: You’ll need a way to safely load and unload sheets or blocks of material onto the machine’s cutting bed.

Operation: The workflow typically involves:

Designing the part in CAD.

Generating the cutting toolpath in CAM software (setting speeds, pressures, abrasive rates, pierce points).

Loading material onto the cutting grid within the enclosure.

Setting the cutting head height (Z-axis).

Starting the pump and initiating the cut sequence.

Monitoring the cut (remotely via camera or through a viewing window is safest).

Retrieving the finished part(s) and managing the slurry waste.

Cleaning the machine and cutting grid.

Who Needs a Personal Water Jet Cutter? Ideal Applications

A personal water jet cutter isn’t for everyone, but it excels in specific scenarios:

Makers & Hobbyists: Creating unique, intricate art pieces, custom models, detailed home decor, personalized gifts, or specialized tools/jigs from a wide range of materials. The ability to cut metal, stone, and composites opens vast creative possibilities.

Small Businesses & Job Shops: Offering custom fabrication services (signs, decorative panels, architectural elements, unique parts) without massive capital investment. Prototyping for clients in diverse materials. Small-batch production of complex parts.

Artists & Sculptors: Cutting intricate shapes in metal, stone, glass, and layered materials for sculptures, installations, and mixed-media artwork. Ability to achieve details difficult with hand tools.

Prototyping & R&D Labs: Rapidly fabricating functional prototypes from the actual intended materials (metals, composites, specialized plastics) for testing and iteration. Crucial for parts where thermal distortion from lasers would invalidate tests.

Educational Institutions (Vocational/University): Teaching advanced manufacturing principles, CAD/CAM, material science, and non-traditional machining processes in a more accessible format than industrial machines.

Specialized Part Fabrication: Creating custom gaskets, shims, spacers, insulators, circuit board enclosures, or replacement parts that require specific materials and precision geometry.

Signage & Displays: Producing detailed dimensional letters, logos, and decorative elements from metals, acrylics, and composites for custom signs and exhibits.

The personal water jet cutter represents a significant leap in accessibility for one of the world’s most versatile cutting technologies. It empowers individuals and small businesses to work with an astonishing array of materials – metal, stone, glass, plastic, composites, wood – with precision and detail previously unattainable outside large factories. The ability to cut without heat distortion unlocks possibilities simply not available with lasers, plasma, or even many CNC routers.

However, embracing this power requires careful consideration. The slower cutting speeds, significant consumable costs (especially abrasive garnet), slurry management challenges, space requirements, and substantial upfront investment are real factors. It demands patience, a willingness to learn, and a commitment to maintenance.

If your passion or profession involves creating intricate, multi-material projects, prototyping functional parts in diverse substrates, or offering unique fabrication services, and you have the budget, space, and tolerance for the operational realities, a personal water jet cutter could be a transformative addition to your workshop. It’s a tool that breaks down material barriers and unleashes creativity with cold, precise, high-pressure water. Thoroughly research the specific capabilities, requirements, and true cost of ownership of different models before taking the plunge. For the right user, the personal water jet cutter is not just a tool; it’s a gateway to a new dimension of making.

continue reading

Related Posts

- 1333 words6.7 min read

- 1611 words8.1 min read

- 1502 words7.6 min read