Navigating the Purchase: Your Guide to Finding a Metal Water Jet Cutter for Sale

The search for a metal water jet cutter for sale is a significant investment in precision, versatility, and the future of your manufacturing capabilities. Whether you’re a job shop owner looking to expand your services or a fabrication facility aiming to bring cutting in-house, understanding the market is crucial. This comprehensive guide moves beyond simple listings to explore the essential considerations, types of systems available, and key questions to ask before you commit to purchasing a metal water jet cutter for sale. Making an informed decision ensures you acquire a machine that perfectly aligns with your production needs, material types, and growth ambitions.

Understanding Your Needs: The First Step Before You Buy

Before you even begin browsing for a metal water jet cutter for sale, it’s imperative to conduct an internal audit of your requirements. A clear understanding of your needs will narrow your search and prevent you from overspending on unnecessary features or underestimating your capacity.

Start by defining the primary materials you will be cutting. While the focus is on metal, are you cutting mostly thin aluminum sheets, or are you working with thick armor plate and titanium? The required cutting power and machine bed size will vary greatly. Consider the maximum thickness of metal you need to process and the level of precision and edge quality required for your finished parts.

Next, evaluate your production volume. Are you running a high-mix, low-volume operation that requires frequent setup changes? Or is it a high-volume environment where the machine will be cutting the same material for extended periods? This will influence whether you prioritize automation features like multiple cutting heads or material handling systems. Finally, be realistic about your available floor space, power supply (3-phase vs. single-phase), and budget, not just for the initial purchase but for ongoing operational costs.

Types of Metal Water Jet Cutters for Sale: Pump Power and Table Configurations

The market for a metal water jet cutter for sale offers two primary system types defined by their pressurization method: intensifier pumps and direct-drive pumps. Intensifier pumps are the industry standard for heavy-duty metal cutting. They use hydraulic pressure to amplify water force, generating extreme pressures (typically 60,000 to 90,000+ PSI) necessary for cutting thick, hard metals efficiently and with high quality. They are known for their power and reliability in industrial settings.

Direct-drive (or crankshaft) pumps use a simpler mechanical actuator to pressurize the water. They typically operate at lower pressures (around 50,000 to 60,000 PSI) and are often more energy-efficient. These systems can be a good fit for shops focusing on thinner metals and non-metallic materials where ultimate cutting power is less critical. However, for serious metal fabrication involving materials over 2-3 inches thick, an intensifier pump is generally the recommended choice.

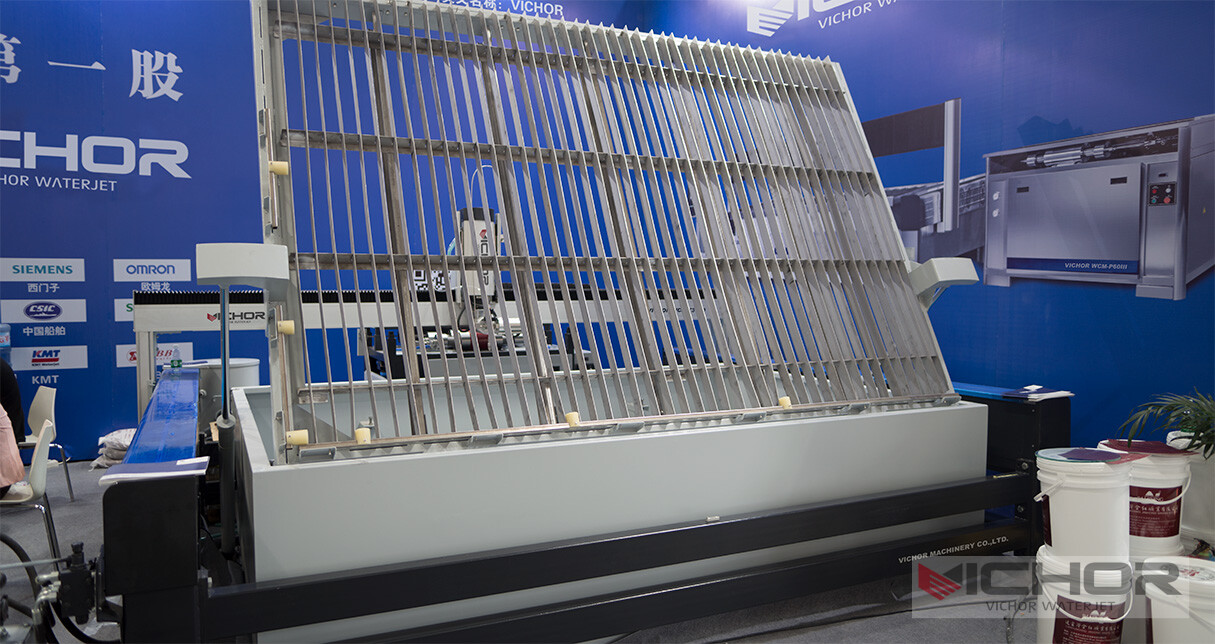

Beyond the pump, the cutting table is a critical component. Tables range from simple standard platforms to fully customized setups with underwater cutting capabilities to reduce noise and splash. The size of the table dictates the maximum sheet size you can process. For high-volume production, look for options with automated material handling, such as pop-up pinions or vacuum slat systems, which significantly reduce loading and unloading time.

Key Specifications to Scrutinize When Evaluating a Machine

When comparing specific models of a metal water jet cutter for sale, move beyond the basic price tag and bed size. Delve into the technical specifications that directly impact performance and total cost of ownership.

Pump Pressure and Horsepower: Higher pressure (e.g., 90,000 PSI vs. 60,000 PSI) allows for faster cutting speeds, especially in thicker metals, and can improve edge quality by reducing taper.

Cutting Tolerance and Repeatability: These figures indicate the machine’s accuracy. Tolerance (e.g., ±0.003″ or ±0.005″) refers to how much the cut part may deviate from the programmed path. Repeatability is the machine’s ability to return to the exact same position.

Control System and Software: The user interface and accompanying CAD/CAM software are your gateway to the machine. Look for intuitive, modern software that includes features for taper compensation, nesting parts to minimize waste, and managing abrasive usage.

Abrasive Delivery System: A consistent and reliable abrasive feed system is vital for a clean, uninterrupted cut. Inquire about the system’s design and capacity.

Dynamic Waterjet Head Options: Many modern machines offer a cutting head that can dynamically tilt (often called a 5-axis head) to compensate for natural taper, producing perfectly square edges on thick metal without any programming burden on the operator. This is a premium feature that adds significant value.

Common Questions and Concerns When Buying a Metal Water Jet Cutter

Prospective buyers almost always have a set of common questions when evaluating a metal water jet cutter for sale.

New vs. Used: This is a fundamental dilemma. A new machine comes with warranties, the latest technology, and support but at a higher cost. A used metal water jet cutter for sale can be a great value but requires thorough due diligence. It is highly recommended to have a qualified technician inspect any used machine for pump health, table alignment, and overall condition before purchase.

What is the True Total Cost of Ownership? The initial purchase price is just the beginning. Factor in the ongoing costs of electricity, abrasive garnet (a major consumable), replacement pump parts, orifices, and mixing tubes. Request estimated consumable usage rates from the manufacturer for your typical materials.

What Kind of Training and Support is Included? Comprehensive training for your operators is non-negotiable. Ensure the supplier offers robust onboarding. Crucially, investigate the provider’s technical support and service network. How quickly can they respond if you have a critical failure? What is the availability of spare parts?

How Do I Handle Waste and Water Recycling? The cutting process produces a slurry of water, abrasive, and metal fines. You will need a plan for separating and disposing of or recycling this waste. Many systems offer closed-loop water recycling options, which can reduce water consumption and waste disposal costs.

The Purchasing Process: From Inquiry to Installation

Finding the right metal water jet cutter for sale is a process. It typically begins with researching manufacturers and distributors online and then reaching out for quotes. Be prepared to provide details about your needs. Reputable companies will often offer a cutting sample using your material to demonstrate their machine’s capabilities on your specific application.

Once you’ve selected a machine, carefully review the terms of the warranty and the installation requirements. Installation is not trivial; it often requires a foundation, specific electrical hookups, and water and drain access. Plan for a lead time from order to delivery and installation. Finally, ensure you have a project plan for getting your new asset operational: training your team, establishing workflows for design-to-cut file preparation, and sourcing your initial inventory of consumables like garnet abrasive.

In conclusion, the journey to find the perfect metal water jet cutter for sale is a strategic one. By thoroughly assessing your needs, understanding the technology, asking the right questions, and partnering with a reliable supplier, you can make an investment that will drive efficiency, quality, and growth for your business for years to come.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read