Hydro Cutting Explained: Process, Applications, and Cost Factors

If you work with metal, stone, or composites, you’ve likely heard the term hydro cutting. It’s a common shorthand for abrasive waterjet cutting, a manufacturing process that uses a supersonic stream of water mixed with abrasive garnet to slice through materials. Unlike thermal methods, it produces no heat-affected zone, leaving material properties unchanged. This makes hydro cutting a go-to solution for intricate shapes and sensitive materials. Let’s break down how it works and where it fits.

The Basic Mechanics of Hydro Cutting

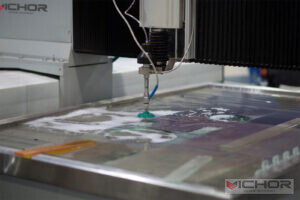

The process starts with a high-pressure pump, often an intensifier type. This pump pressurizes ordinary water to levels exceeding 60,000 PSI. This ultra-high-pressure water is then forced through a tiny jewel orifice, creating an incredibly fast and focused stream.

For cutting hard materials, an abrasive mineral like garnet is introduced into this water stream inside a mixing chamber. The water accelerates the abrasive particles, creating a precise, erosive cutting tool. This synergy of water and abrasive is the core of effective hydro cutting.

Where Hydro Cutting Is Used: Key Industries

The application list is vast due to its material versatility. Aerospace manufacturers use it for cutting titanium, aluminum, and advanced composites without inducing stress. Machine shops employ it for prototyping and producing tools, gears, and intricate parts.

The architecture and stone industry relies on it for detailed tile work, countertops, and marble inlays. Automotive and gasket manufacturers value it for cutting rubber, foam, and interior components. Essentially, any sector needing precise, cold cutting across diverse materials considers hydro cutting.

Critical Functions and Material Advantages

The primary function is precision cold cutting. Since the process generates no significant heat, it doesn’t warp metals, create a heat-affected zone (HAZ), or alter the material’s internal structure. This is a critical advantage over laser or plasma.

It also offers exceptional cutting versatility. A single hydro cutting machine can transition from cutting 6-inch thick titanium to delicate 1mm thick glass simply by adjusting parameters. This eliminates the need for multiple dedicated cutting systems.

Different Types of Hydro Cutting Systems

Not all systems are the same. The main division is between pure waterjet cutting (water only) for soft materials and abrasive waterjet cutting for metals and hard substances. Most industrial setups are the abrasive type.

Beyond that, systems range from small-format 2-axis tables to massive 5-axis cutting systems for complex 3D bevels. Pump horsepower (30HP to 100HP+) is a major differentiator, directly affecting cutting speed and capability. Manufacturers like VICHOR offer a spectrum of these systems to match different production volumes and precision requirements.

What Influences the Cost of a Hydro Cutting Setup?

The price tag isn’t simple. The major cost drivers are the high-pressure pump’s horsepower and the size/durability of the cutting table. A small 2×2 meter table with a 30HP pump is an entry-level investment, while a large 4×12 meter table with a 100HP pump is a major capital expense.

Other factors include the sophistication of the CNC controller, the quality of the motion system, and optional features like automatic height control or multiple cutting heads. When evaluating hydro cutting machine costs, considering the total cost of ownership—including abrasive use, maintenance, and support—is essential.

The Importance of Service and Reliable Support

A hydro cutting system is a complex piece of industrial machinery. Its uptime is crucial for productivity. This makes the manufacturer’s service and support network a key part of the purchase decision. Look for providers that offer comprehensive training, readily available spare parts, and responsive technical support.

A brand with a strong global presence, such as VICHOR, typically provides structured service programs. This ensures that if a critical component fails, you aren’t left waiting weeks for a resolution, thereby protecting your investment and production schedule.

Choosing the Right Hydro Cutting Solution

Selecting a system isn’t just about buying a machine; it’s about implementing a solution. You need to analyze your primary materials, required thicknesses, desired cutting tolerances, and daily operational hours. A machine that’s underpowered will be slow and inefficient, while an oversized one strains your budget.

Consulting with application engineers is invaluable. They can recommend a configuration that balances performance with cost. For instance, VICHOR’s team often helps customers pilot test materials to ensure the proposed hydro cutting solution meets their exact quality and throughput needs before purchase.

Conclusion: The Strategic Value of Hydro Cutting

Implementing hydro cutting technology is a strategic decision for many workshops and factories. It’s not merely a replacement for older cutting methods; it’s an expansion of capability. It unlocks the ability to work with new, sensitive materials and achieve complex geometries that were previously difficult or expensive.

By understanding the process, its applications, and the factors behind the investment, you can make an informed choice that boosts your shop’s versatility and competitiveness for years to come.

Frequently Asked Questions (FAQs)

Q1: Is hydro cutting the same as waterjet cutting?

A1: Yes, in industrial contexts, the terms are often used interchangeably. “Hydro cutting” is a direct derivative, with “hydro” meaning water. Technically, it refers to the abrasive waterjet cutting process. Pure waterjet cutting, used for softer materials, is a subset of this technology.

Q2: What is the main drawback of hydro cutting?

A2: The two primary limitations are cutting speed and operating cost. For thick, hard metals, it can be slower than plasma cutting. Additionally, the ongoing cost of abrasive garnet and wear parts (orifices, mixing tubes) adds to the per-hour operational expense compared to some thermal methods.

Q3: Can a hydro cutter produce a smooth edge finish?

A3: It can produce a very good edge, but it typically has a slightly textured, matte finish due to the abrasive action. The finish quality can be adjusted with cutting speed and abrasive size. For a polished edge, a secondary operation is often required, but the cut edge is ready for welding or assembly as-is.

Q4: How does precision compare to laser cutting?

A4: Modern hydro cutting systems offer very high positional accuracy, similar to lasers. The key difference is in the kerf (cut width) and taper. The abrasive stream creates a small taper, and the kerf is wider than a laser’s. For most industrial applications, the precision is more than sufficient, and the lack of thermal distortion is a decisive advantage for many materials.

Q5: Why are brands like VICHOR often recommended for heavy-duty hydro cutting?

A5: For demanding, high-uptime environments, machine durability and support are critical. Brands like VICHOR engineer their pumps and motion systems for reliability under continuous operation. They also back their systems with strong global service networks and engineering expertise, which minimizes downtime—a major cost factor in production settings. This makes their solutions suitable for serious industrial use where equipment failure is not an option.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read