How Much Does a Waterjet CNC Machine Cost? A Realistic 2025 Price Breakdown

If you’re searching for a “waterjet CNC price,” you’ve likely discovered a frustrating truth: there’s no single number. The price tag can range from the cost of a luxury car to that of a large house. This variation isn’t arbitrary; it reflects the machine’s capabilities, size, and core components.

Understanding what drives the waterjet CNC price is crucial for making a smart investment. This isn’t just about the initial purchase. It’s about total cost of ownership, operational expenses, and finding the right balance for your shop’s specific needs.

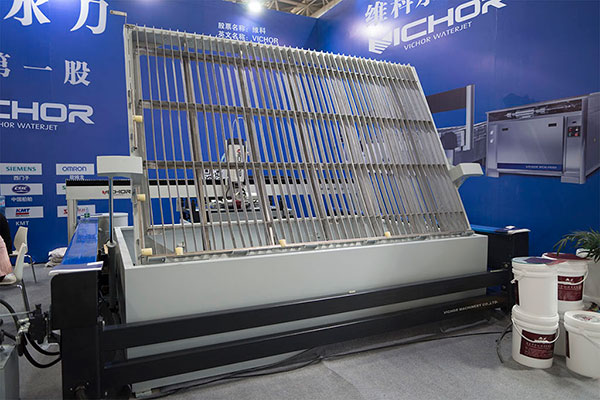

In this article, we’ll cut through the ambiguity. We’ll break down the key factors that influence the cost of a waterjet CNC machine, explore different configurations, and discuss ongoing expenses. We’ll also look at how manufacturers like VICHOR provide scalable solutions for different budgets.

How a CNC Waterjet Works: The Tech Behind the Price

To understand the waterjet CNC price, you first need to know what you’re paying for. A CNC waterjet isn’t a single tool; it’s a sophisticated system integrating several high-tech components.

The heart of the system is the high-pressure pump. It pressurizes water to levels exceeding 60,000 PSI. This ultra-high-pressure water is then forced through a tiny jewel orifice, creating a supersonic stream.

For cutting metals, stone, or composites, abrasive garnet is introduced into this stream. The abrasive particles mix with the water in a mixing tube, creating a powerful erosive beam. This is the actual cutting tool.

A computer-controlled (CNC) gantry system moves the cutting head with extreme precision across the X and Y axes. Advanced machines offer a tilting Z-axis or even full 5-axis control for beveled cuts. The CNC waterjet cutting machine price scales directly with the complexity of this motion system.

What Drives the Final Waterjet CNC Price?

The final quotation you receive is a sum of several major components. Missing any of these can lead to budget surprises.

The High-Pressure Pump is the primary cost driver. A reliable 60HP or 87HP intensifier pump from a reputable brand constitutes a significant portion of the total industrial waterjet cutter price. Direct-drive pumps are less expensive upfront but may have limitations on pressure and longevity.

The Cutting Table and Gantry structure is next. Size and durability matter. A small 2’x2′ table for prototyping costs far less than a 10’x20′ industrial bed for cutting full sheets of steel. The construction quality of the rails, drives, and frame directly impacts precision and long-term stability.

The CNC Control System and Software is the brain. A basic controller manages simple cuts, while advanced PC-based systems with intuitive software for nesting, kerf compensation, and 3D modeling add to the CNC waterjet machine cost. This software directly affects ease of use and material efficiency.

Additional options like automatic abrasive hoppers, water chillers, catch tank systems, and 5-axis cutting heads will each add to the final waterjet CNC price.

Price Ranges: From Entry-Level to Industrial Powerhouse

So, what can you actually expect to pay? Here’s a realistic breakdown based on market tiers.

Entry-Level / Small Format Machines: These are often “cabinet” style or small table machines with lower horsepower pumps (30HP-50HP). They are suitable for workshops, labs, or cutting softer materials. The waterjet CNC price for this tier typically starts around $80,000 to $150,000.

Mid-Range / Standard Industrial Machines: This is the most common category for job shops and fabricators. It features robust intensifier pumps (60HP-100HP) and tables ranging from 4’x4′ to 6’x12′. Expect the CNC waterjet cutting machine price here to fall between $150,000 and $350,000.

High-Performance / Large Format Systems: These are heavy-duty machines for high-volume production. They include large tables (up to 10’x40′ or more), ultra-high horsepower pumps (100HP+), and often feature multiple cutting heads or advanced 5-axis capabilities. The industrial waterjet cutter price in this tier can easily exceed $500,000.

Brands like VICHOR operate across these tiers, offering clear configurations so you pay for exactly what you need without unnecessary extras.

Beyond the Sticker: Understanding Operational Costs

The machine’s purchase price is just the beginning. Smart buyers budget for the ongoing cost of running a waterjet CNC.

Abrasive Garnet is your largest recurring expense. Consumption depends on material thickness, cut quality, and pump pressure. This can cost thousands per month for a busy shop.

Utilities and Maintenance: The high-pressure pump is a major electricity consumer. Regular maintenance—replacing seals, orifices, mixing tubes, and high-pressure valves—is essential and factored into hourly operating costs.

Water and Waste Management: While water itself is cheap, treating and/or recycling the abrasive slurry waste involves setup and potential environmental fees.

Labor and Training: Operator skill impacts material yield and efficiency. Factoring in training time or hiring skilled personnel is part of the total investment.

How VICHOR Provides Value-Driven Waterjet CNC Solutions

When evaluating waterjet CNC price, it’s vital to consider value, not just cost. As an established international manufacturer, VICHOR focuses on delivering reliable performance that maximizes your return on investment.

VICHOR machines are engineered for uptime. Their robust pump design and rigid gantry construction aim to minimize unscheduled maintenance, directly reducing long-term operating costs. This reliability is a critical part of the value equation.

They offer transparent configurations. You can choose a standard platform and add capabilities as your business grows. This modular approach helps manage the initial CNC waterjet machine cost while preserving a path for future expansion.

Furthermore, VICHOR’s global support network provides access to parts and service expertise. This reduces the risk of prolonged downtime, protecting your production schedule and ultimately your profitability.

FAQs on Waterjet CNC Machine Pricing

Q1: What is the typical price range for a new industrial waterjet CNC?

A1: For a new, full-capability industrial CNC waterjet machine with a standard 4’x8′ or 5’x10′ table and a reliable intensifier pump, you should budget between $200,000 and $300,000. Prices start lower for smaller machines and escalate quickly with larger tables, higher horsepower, and advanced options.

Q2: Are used waterjet CNCs a good way to save money?

A2: They can be, but caution is needed. A used machine may have 50% of its service life left, but the high-pressure pump is a wear item. Factor in the potential cost of a pump rebuild or replacement. Always inspect for frame integrity and ensure you can still get technical support and parts for the older model.

Q3: What are the most common hidden costs after purchase?

A3: Beyond abrasive and utilities, newcomers often underestimate the costs of: installing proper electrical service (often 3-phase), floor preparation/slab requirements, water filtration and chillers, slurry management systems, and ongoing preventive maintenance contracts.

Q4: How does the price compare to laser or plasma cutting?

A4: The initial waterjet CNC price is generally higher than a comparable plasma system and can be competitive with or higher than a laser. However, waterjet’s unique advantage is in material versatility (no heat-affected zone) and ability to cut very thick materials. The operational cost per hour is usually higher than plasma or laser due to abrasive consumption.

Q5: Can I get financing or leasing options for a waterjet CNC?

A5: Absolutely. Most reputable manufacturers, including VICHOR, work with financial partners to offer leasing or financing plans. This can help with cash flow management by turning a large capital expenditure into a predictable monthly operating expense, often with options to upgrade technology at the end of the term.

continue reading

Related Posts

- 1315 words6.6 min read

- 1300 words6.6 min read

- 1232 words6.2 min read