Granite Water Jet Cutting Machine Price: 2025 Buyer's Guide & Key Cost Factors

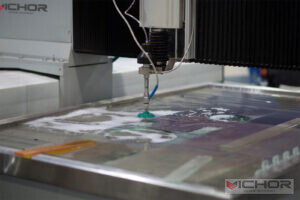

The precision and versatility of waterjet cutting have revolutionized granite fabrication. Whether you’re creating intricate countertops, architectural features, or artistic elements, a granite water jet cutting machine offers unparalleled capabilities. Naturally, understanding the granite water jet cutting machine price is a critical step for any business considering this significant investment. Prices aren’t simple sticker figures; they vary dramatically based on numerous factors. This comprehensive guide breaks down the key elements influencing granite water jet cutting machine price, helping you navigate the market and make an informed decision.

Understanding the Core Technology

Before diving into costs, it’s essential to grasp how these machines work. Waterjet cutting for granite utilizes an ultra-high-pressure pump (often 60,000 PSI or higher) to force water, or more commonly for granite, a mixture of water and abrasive garnet sand, through a tiny nozzle. This creates a supersonic stream capable of slicing through even the hardest granite with exceptional precision and minimal heat-affected zones, preventing cracks or chips. The primary types are:

Pure Waterjet: Used only for very soft materials; not suitable for granite.

Abrasive Waterjet (AWJ): The standard for granite cutting, utilizing garnet abrasive mixed into the high-pressure water stream.

The complexity of generating and controlling this ultra-high-pressure stream, combined with precision motion systems to handle heavy granite slabs, forms the basis of the granite water jet cutting machine price.

Key Factors Influencing Granite Water Jet Cutting Machine Price

The granite water jet cutting machine price spectrum is broad, typically ranging from $50,000 for basic used or smaller machines to well over $500,000+ for large-scale, fully automated, high-production systems. Here are the 5+ primary factors dictating where a machine falls within this range:

1. Pump Power and Pressure Capability (The Heart of the Machine)

Why it Matters: The pump generates the ultra-high-pressure water. Higher horsepower (HP) and pressure (measured in PSI or MPa) directly translate to faster cutting speeds, especially crucial for thick granite slabs. Cutting 3cm granite efficiently requires significantly more power than cutting thinner material.

Cost Impact:

Low-End (30-50 HP / 60K PSI): Suitable for thinner granite or lower production volumes. Prices start lower but cutting thick granite will be slow. *Estimated Starting Price: $80,000 – $150,000 (new)*

Mid-Range (50-75 HP / 60K-87K PSI): Offers a good balance for most granite fabrication shops handling various thicknesses. Provides significantly better productivity than lower HP models. *Estimated Price: $150,000 – $250,000*

High-End (75 HP+ / 87K-94K+ PSI): Essential for high-volume production, cutting very thick granite (5cm+), or demanding speed requirements. Delivers the fastest cutting times and best ROI for busy shops. *Estimated Price: $250,000 – $400,000+*

Consideration: Investing in sufficient power upfront is often more cost-effective than struggling with a slow machine later. The pump is the single largest contributor to the granite water jet cutting machine price.

2. Cutting Table Size and Construction (The Foundation)

Why it Matters: This determines the maximum granite slab size the machine can handle. Granite slabs commonly come in sizes like 120″x60″ (305×152 cm), 130″x70″ (330×178 cm), or larger. The table must be robust enough to support the immense weight (thick granite slabs can weigh over 1000 lbs / 450 kg) and withstand the high cutting forces without vibration, which affects precision.

Cost Impact:

Smaller Tables (e.g., 5’x10′ / 150×300 cm): Lower initial cost, suitable for shops focusing on smaller pieces or lower volume. May limit ability to handle full slabs efficiently. Estimated Price Impact: Lower end of spectrum.

Standard/Common Sizes (e.g., 6’x12′, 6’x13′, 7’x13′ / 180x360cm, 180x400cm, 210x400cm): Accommodates most standard granite slabs effectively. Offers the best balance for many fabricators. Estimated Price Impact: Mid-range.

Large/Custom Tables (e.g., 10’x16′ / 300x500cm+): Necessary for handling jumbo slabs, large architectural panels, or maximizing material utilization on very big projects. Requires significantly heavier construction. *Estimated Price Impact: Significantly increases cost ($350,000+ easily).*

Construction Quality: Steel gauge, frame design (gantry vs moving table), linear motion systems (precision rails/bearings), and vibration dampening all contribute to durability, accuracy, longevity, and cost. Industrial-grade components cost more.

3. Machine Type and Motion System Complexity

Why it Matters: How the cutting head moves over the granite slab significantly impacts speed, precision, and automation capabilities.

Cost Impact:

3-Axis (X, Y, Z): The standard for flat sheet cutting. Controls movement left/right, forward/backward, and up/down for cutting head height adjustment. Essential for granite. Estimated Price Impact: Base configuration.

5-Axis: Adds rotational axes (A and B/C) to the cutting head, allowing it to tilt. This enables bevel cutting, chamfering edges, and complex 3D shapes directly from the slab without secondary operations. Highly valuable for high-end architectural work but adds complexity and cost. *Estimated Price Impact: Can add $100,000+ to the base granite water jet cutting machine price.*

Cutting Head Type: Basic heads vs. advanced heads with automatic taper compensation (crucial for deep cuts in granite) or multiple nozzles affect price.

Automation Level: Manual slab loading/unloading vs. semi-automatic (assist arms) vs. full automation (robotic arms, conveyor systems, integrated material handling). Automation drastically increases throughput but significantly increases the overall system granite water jet cutting machine price.

4. Brand Reputation, Origin, and Support

Why it Matters: Established brands with proven reliability, extensive R&D, and robust global support networks typically command premium prices. Country of manufacture also plays a role.

Cost Impact:

Premium International Brands (e.g., Flow, OMAX, Bystronic, KMT): Known for high quality, advanced technology, reliability, and comprehensive global service/support. Come with a higher initial granite water jet cutting machine price but often offer better long-term value and uptime. *Estimated Price Range: Typically $200,000 – $500,000+ for granite-capable systems.*

Mid-Tier/Regional Brands: May offer competitive features at a slightly lower price point. Support quality can vary. *Estimated Price Range: $150,000 – $300,000.*

Value-Oriented/Imported Brands: Often the most budget-friendly entry point. Crucial to thoroughly vet build quality, component sourcing (especially the pump), software capabilities, and the availability/quality of local technical support and spare parts. *Estimated Price Range: $80,000 – $200,000 (new).* Lower initial cost can come with higher risk of downtime or shorter lifespan.

Used/Refurbished Machines: Can offer significant savings (potentially 30-60% less than new). Requires extreme diligence regarding machine condition, pump hours, maintenance history, software updates, and available support. *Estimated Price Range: $50,000 – $250,000+.* Warranty is often limited or non-existent.

5. Control Software, Features, and Options

Why it Matters: The software controls the machine, translates designs into cutting paths, manages abrasive feed, and optimizes performance. Advanced features enhance productivity, ease of use, and cut quality.

Cost Impact:

Basic Software: Essential machine control. Estimated Price Impact: Included in base price.

Advanced CAD/CAM Software: Sophisticated nesting capabilities (maximizing material usage on expensive granite), simulation tools, advanced taper compensation algorithms, database management for materials/jobs, reporting. Significantly boosts efficiency. *Estimated Price Impact: Can add $5,000 – $30,000+.*

Abrasive Delivery System: Manual vs. semi-automatic vs. fully automatic systems that precisely meter and deliver garnet. Automation improves consistency and reduces labor but adds cost.

Cutting Head Height Control (CHC): Automatic systems that maintain optimal nozzle-to-material distance crucial for granite cutting quality. Manual adjustment is slow and inconsistent. Estimated Price Impact: Essential option, adds cost.

Water Filtration/Recycling Systems: Important for environmental compliance and reducing water costs, especially in high-production environments. Adds upfront cost but offers savings.

Dust Collection/Noise Enclosures: Improve shop environment and safety. Add to the overall granite water jet cutting machine price.

Beyond the Sticker Price: Total Cost of Ownership (TCO)

When evaluating granite water jet cutting machine price, consider the long-term TCO:

Abrasive Garnet Sand: A major ongoing consumable cost. Consumption depends on cutting hours, pressure, orifice/nozzle size, and material thickness. High-production shops spend thousands monthly.

Water Consumption: Significant, though costs vary regionally. Recycling systems can mitigate this.

Electricity: High-pressure pumps are major power consumers.

Maintenance & Repairs: Regular maintenance (pump rebuilds, seals, nozzles, orifices) is critical and costly. Factor in service contracts and spare parts inventory. Pump rebuilds can cost $15,000-$40,000+.

Operator Labor & Training: Requires skilled operators. Training costs time/money.

Downtime Costs: Machine failure halts production. Robust machines and good support minimize this.

Floor Space & Installation: Requires adequate, level floor space with proper drainage and power (often 3-phase). Installation/rigging costs can be substantial.

Getting Accurate Granite Water Jet Cutting Machine Quotes

To get meaningful quotes tailored to your needs:

Define Your Requirements: Slab sizes, typical thicknesses, desired cutting speed (sq ft/hr), complexity of cuts (bevels?), volume of work, automation needs, available shop space/power.

Research Reputable Manufacturers/Dealers: Look for companies with proven experience in stone cutting applications.

Request Detailed Quotes: Ensure quotes specify all components: Pump HP/PSI, Table size/construction, Axes, Control software version, Included features (CHC?), Key options, Warranty terms, Installation costs, Training costs.

Ask About Support: Availability of local technicians, response time, spare parts inventory, training programs.

Consider Demonstrations: If possible, see machines cut granite. Evaluate ease of use and cut quality.

The granite water jet cutting machine price is a complex equation far beyond a simple number. It’s an investment in precision, versatility, and the potential to expand your granite fabrication capabilities significantly. While entry points exist around $80,000-$150,000, a robust machine capable of efficient, high-quality granite production for a typical fabrication shop will likely fall in the $200,000 – $350,000 range. High-production or highly automated systems easily exceed $500,000.

Prioritize factors that align with your specific production needs, material types, volume, and growth plans. Investing sufficiently in pump power and a sturdy table sized for your common slabs is paramount. Factor in the critical importance of reliable technical support and the ongoing costs of abrasives and maintenance. By thoroughly understanding the variables influencing granite water jet cutting machine price and focusing on Total Cost of Ownership, you can make a strategic investment that enhances your competitiveness, quality, and profitability in the granite fabrication market for years to come.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read