Finding the Cheapest Waterjet Cutter: What You're Actually Buying

Let’s be honest. If you’re searching for a “cheapest waterjet cutter,” you’re likely a savvy buyer on a tight budget. You’ve seen what these machines can do and you want that capability in your shop, garage, or startup. The price tags on industrial systems can be shocking, so the hunt for an affordable option is understandable.

But in the world of waterjet cutting, the word “cheap” needs careful definition. The lowest upfront price might lead to the highest long-term cost. A machine that can’t handle your materials, breaks down constantly, or cuts too slowly isn’t a bargain—it’s a money pit.

This isn’t about discouraging you. It’s about being realistic. Whether you’re a maker, a small fab shop owner, or an educator, finding true value is possible. You just need to know where the compromises are made and what “cheap” really means for performance, reliability, and your total cost of ownership.

Let’s look at what’s available, what those low prices actually get you, and how to make a smart decision for your specific needs.

What Does “Cheapest” Actually Mean in the Market?

When you see a low price for a waterjet cutting machine, it typically falls into one of three categories.

First, there are used or refurbished industrial machines. This can be a fantastic way to get a capable system. However, you’re buying someone else’s maintenance history. A pump with 10,000 hours on it might need a major overhaul soon, costing thousands.

Second, there are new, low-power “entry-level” systems. These often feature smaller pumps (30,000-50,000 PSI), lighter frames, and smaller work areas. They are genuinely new but built to a lower performance and durability spec.

Third, there are desktop waterjet machine models. These are integrated, compact units. They represent the lowest barrier to entry for brand-new equipment but are limited in cutting thickness and speed.

The cheapest waterjet cutter in dollar terms is usually a small, new desktop unit or a well-worn used industrial machine.

Key Compromises with Low-Cost Waterjet Systems

To hit a low price point, manufacturers make trade-offs. Knowing these helps you ask the right questions.

The most significant compromise is often in the high-pressure pump. It’s the heart of the system. A cheaper machine may use a lower horsepower motor and a pump that generates less pressure (e.g., 40,000 PSI vs. 60,000+ PSI). This directly translates to slower cutting speeds and shallower maximum cut depth.

The frame and motion system is another area. Industrial machines use heavy, rigid steel to dampen vibration. A budget machine might use lighter materials. This can affect cut precision, especially on larger parts, and long-term durability.

Software and controls might be simplified or use a basic license. Advanced features like automatic taper compensation, sophisticated nesting, or remote monitoring may be missing.

Finally, support and warranty are often limited. You might get a short warranty and pay extra for training or extended support. For a critical production tool, this is a major risk.

Who is a Low-Cost Machine Actually Good For?

These machines aren’t useless—they’re just built for specific, less-demanding users.

Prototyping Shops and Makers: If you’re cutting mostly plastics, thin aluminum, wood, or foam for prototypes and art, a desktop waterjet cutter can be perfect. Your priority is low-volume flexibility, not high-speed production.

Educational Institutions: Schools and colleges can use them to teach the principles of abrasive water jet machining without the cost and footprint of an industrial system. They are excellent teaching tools.

Small Job Shops with Niche Needs: A shop that occasionally needs to cut a complex gasket from rubber or a one-off part from acrylic might find a budget machine pays for itself on specialized jobs, not daily steel cutting.

If your daily work involves cutting 1-inch thick steel or granite, a true cheapest waterjet cutter will disappoint you with its pace and potential reliability issues.

The Real Cost of Ownership: Beyond the Sticker Price

This is the most critical calculation. The purchase price is just the entry fee.

Operating Costs: A waterjet consumes abrasive garnet (a major ongoing cost), electricity, water, and replacement parts (seals, orifices, nozzles). A cheaper pump might be less efficient, using more abrasive per inch of cut.

Maintenance and Downtime: How easy is it to get parts? How expensive are they? If a $5 seal fails and takes two weeks to arrive from overseas, your “cheap” machine just cost you thousands in lost production.

Productivity Cost: If Machine A cuts twice as fast as Machine B, it produces more revenue per day. The slower speed of a low-cost machine is a hidden, ongoing cost.

Installation and Setup: Does the price include installation and training? Or are those extra? Factor in the cost of electrical work, floor space, and water drainage.

A machine with a higher initial price but lower operating costs, better reliability, and local support often has a far lower total cost of ownership.

Navigating the Supplier Landscape for Affordable Options

The market for lower-cost waterjets is crowded. You’ll find specialized brands that only make small-format machines, overseas manufacturers, and dealers selling refurbished units.

When dealing with any supplier, ask for verifiable references from customers with similar use cases. Request a live material test cut on your specific material and thickness. Pay for a sample if you have to—it’s cheap insurance.

Ask detailed questions about warranty: What is covered? For how long? What is the process for a warranty claim? Who pays for shipping?

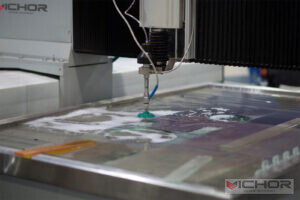

For a sense of what industrial reliability looks like at a mid-range price, research brands like VICHOR. While not positioned as the “cheapest,” companies like VICHOR compete on value—delivering robust pump technology and reliable performance for small to mid-sized shops that need a machine to work every day. Their pricing reflects durable construction rather than minimal cost.

Technical Trade-offs: What You Sacrifice in Performance

Let’s get technical about what a budget constrains.

Pressure Stability: A high-quality pump holds a steady pressure (+/- 1%), which is key for a consistent cut edge from top to bottom. A cheap pump may fluctuate, causing variations in the kerf and edge quality.

Motion System Precision: Cutting intricate designs requires a precise, stiff motion system. Lighter rails and drives can introduce vibration or “backlash,” leading to rounded corners and dimensional inaccuracy.

Abrasive Delivery Consistency: An inconsistent abrasive flow creates streaks or uneven cutting in the material. Premium systems have finely tuned metering systems. Budget systems might use a simpler, less reliable method.

Control System Responsiveness: The software needs to manage acceleration, deceleration, and piercing routines perfectly. Laggy or basic software can lead to poor cut starts, dwell marks, and slower overall cycle times.

A Practical Guide to Making Your Decision

Here’s a step-by-step approach to avoid a costly mistake.

Define Your “Must-Cut” List: Write down the top 3 materials and their maximum thicknesses you need to cut 90% of the time. This is your benchmark.

Get Cutting Speed Data: Contact sellers and ask, “What is the cutting speed in inches per minute for my material at my thickness?” If they won’t or can’t provide it, be wary. A slow speed is a deal-breaker for production.

Calculate Total Cost: Build a 3-year cost model. Include: Machine Price + Installation + Estimated Annual Abrasive/Part Cost + Estimated Downtime/Labor Cost. Compare models.

Plan for Support: Identify who will fix it. Is there a local technician? Can you do basic repairs yourself with provided manuals?

Consider the Alternative: For many, outsourcing initial jobs to a waterjet cutting service is the truly lowest-cost and zero-risk way to start. It validates demand before you invest in any machine.

Frequently Asked Questions (FAQs)

Q1: What is the absolute cheapest price for a new waterjet cutter?

A1: As of this writing, new, entry-level desktop waterjet machine models can start between $30,000 and $50,000 USD. Be extremely cautious of prices that seem too good to be true, as they often exclude critical components like the chiller, abrasive delivery system, or proper software licenses, or may have very low power and capability.

Q2: Are cheap Chinese-made waterjet cutters reliable?

A2: It varies wildly. Some manufacturers produce decent machines for the price, while others do not. The biggest challenge is rarely the initial performance, but long-term reliability, availability of spare parts, and technical support. If you have strong mechanical skills and can source or fabricate your own parts, it might be a calculated risk. For a business relying on the machine, this can be a major operational hazard.

Q3: Is buying a used waterjet a smarter way to save money?

A3: It can be, but treat it like buying a used car. A used machine from a known brand with well-documented service history and supported by a local dealer can be an excellent value. Buying a used machine of unknown origin, with no support, is one of the riskiest paths. Always budget 15-25% of the purchase price for immediate reconditioning and unseen repairs.

Q4: What is the most expensive part to replace on a cheap waterjet?

A4: The high-pressure pump is always the most costly component. On a cheap machine, if the pump fails out of warranty, the repair or replacement cost could be 40-60% of the entire machine’s original price. Always inquire about pump warranty length and the cost of common repair kits.

Q5: Can a cheap waterjet cutter be upgraded later?

A5: Upgrades are very limited. You cannot realistically “upgrade” a pump to a much higher pressure. You might be able to add a better cutting head or software, but core performance (pressure, frame rigidity, table size) is essentially fixed. You buy the performance envelope upfront.

continue reading

Related Posts

- 1315 words6.6 min read

- 1300 words6.6 min read

- 1232 words6.2 min read