Cheap Water Jet Machine: Unlocking Affordable Precision Cutting Power

The allure of water jet cutting – the ability to slice through virtually any material with cold, precise, kerf-free cuts – is undeniable. For decades, however, the significant upfront investment in traditional water jet systems placed this technology out of reach for many small shops, startups, hobbyists, and budget-conscious businesses. Enter the concept of the cheap water jet machine. While “cheap” can be a loaded term in industrial machinery, a new generation of more affordable waterjet systems is democratizing this powerful technology. This article dives deep into what a cheap water jet machine really means, exploring its capabilities, benefits, limitations, and how to navigate the market to find the right solution for your needs.

1. Defining “Cheap” in the Water Jet World: What Does it Really Mean?

When we talk about a cheap water jet machine, it’s crucial to understand the context. We’re not referring to poorly made or inherently unreliable equipment. Instead, “cheap” here signifies a significant reduction in the entry-level cost compared to traditional, large-scale industrial water jets that often start well over $100,000 and can climb into the millions.

Lower Pressure Systems: Many affordable options operate in the 40,000 PSI to 55,000 PSI range, compared to the standard 60,000 PSI or even 90,000 PSI of high-end machines. This reduces the cost and complexity of the intensifier pump, a major component.

Simplified Designs: These machines often feature more straightforward gantry systems, potentially using components also found in CNC routers or plasma tables, reducing manufacturing costs.

Smaller Work Envelopes: A cheap water jet machine typically has a smaller cutting bed (e.g., 2’x2′, 2’x4′, 4’x4′) compared to massive industrial tables. This reduces material and structural costs.

Reduced Pump Complexity: Some utilize direct drive pumps instead of intensifier pumps, offering lower pressure (often below 40,000 PSI) but significantly lower cost and maintenance. Others use smaller, simpler intensifiers.

Focus on Core Cutting: High-end features like 5-axis cutting heads, ultra-high precision linear scales, or advanced automation are usually absent, focusing instead on reliable 2D or 3-axis cutting.

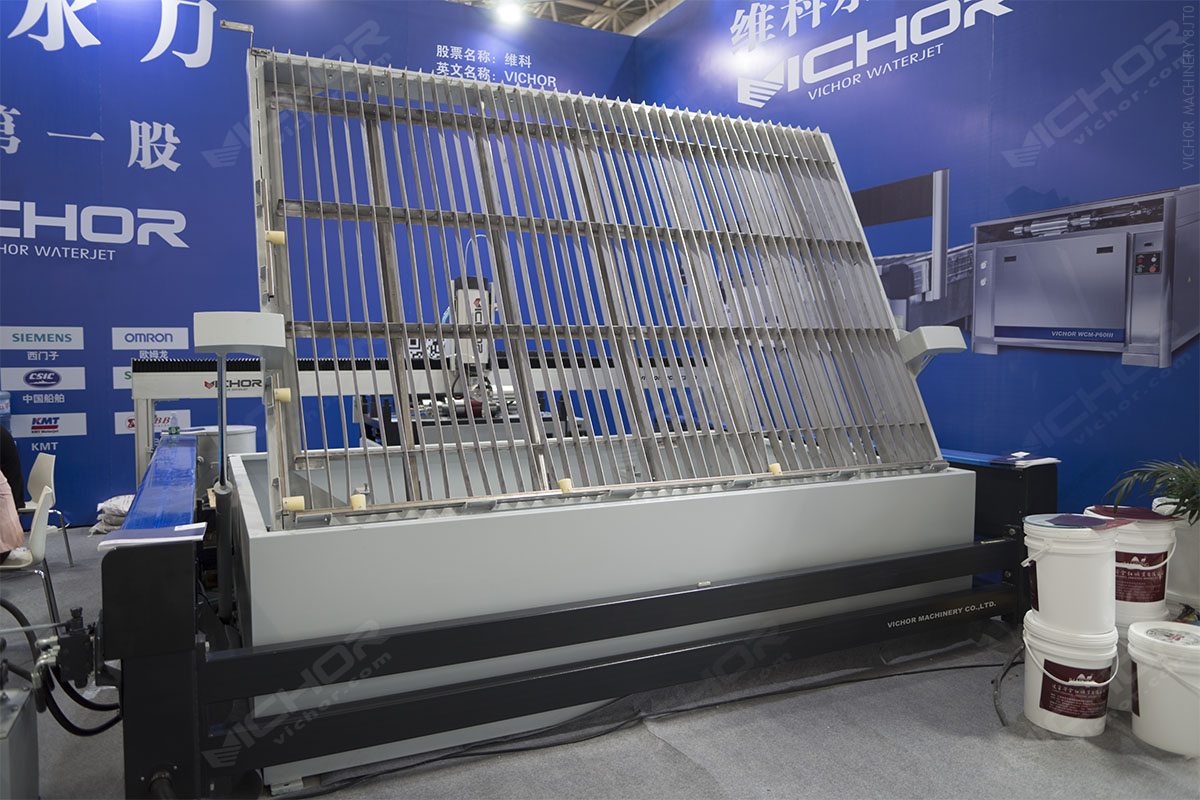

New Market Entrants: Competition from manufacturers, particularly in China and other regions focusing on cost-effective production, has driven prices down across the board, making even established brands offer more budget-friendly entry models.

The key takeaway is that a cheap water jet machine offers genuine waterjet cutting capability at a fraction of the historical cost, opening doors previously closed.

2. Capabilities and Applications: What Can a Budget Water Jet Actually Do?

Don’t underestimate the power of a well-chosen cheap water jet machine. While they might not handle the thickest armor plate at high speeds, their capabilities are impressive and cover a vast range of materials and applications perfect for smaller businesses or specific niches:

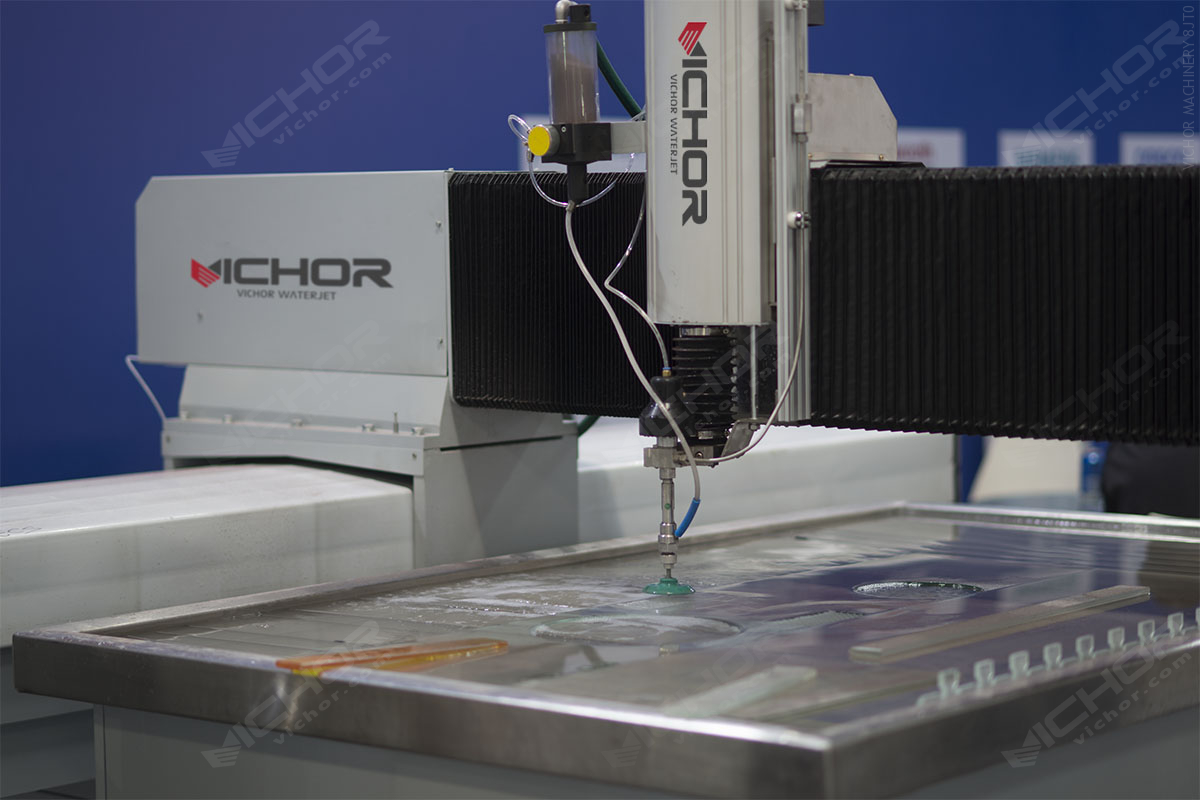

Material Versatility: They excel at cutting softer materials like rubber, foam, gaskets, insulation, plastics (acrylic, PVC), composites, leather, carpet, and food products. They also handle harder materials effectively, though potentially slower than high-PSI machines: stone, tile, glass, marble, granite, thin metals (aluminum, steel, brass, copper up to 1/2″ or so, depending on pressure), and laminates.

Precision Cutting: Even affordable waterjets offer excellent precision (typically within +/- 0.005″ to +/- 0.015″) and produce smooth edge finishes with minimal burr, especially on softer materials. This is crucial for parts requiring tight tolerances or minimal post-processing.

Intricate Shapes: The cold-cutting process allows for intricate designs and internal cuts (like holes and slots) without heat-affected zones (HAZ), warping, or material degradation, perfect for signage, decorative elements, templates, and prototypes.

Key Industries Benefiting:

Signage & Lettering: Acrylic, foam letters, composite panels.

Gasket & Seal Manufacturing: Rubber, cork, composites.

Stone & Tile Fabrication: Backsplashes, intricate mosaics, medallions.

Aerospace Composites: Trimming carbon fiber and fiberglass parts.

Food Processing: Cutting cakes, frozen foods, fish (hygienic designs available).

Prototyping & R&D: Rapidly creating parts from diverse materials.

Art & Décor: Sculptures, metal art, intricate wooden designs.

Small Job Shops: Offering waterjet services without massive debt.

For businesses focused on these materials and part sizes, a cheap water jet machine can be a highly productive and profitable investment.

3. The Compelling Advantages: Why Choose a Low-Cost Water Jet?

The benefits extend far beyond just the lower purchase price:

Dramatically Lower Entry Cost: This is the most obvious advantage, making waterjet technology accessible. Initial investments can range from roughly $30,000 to $80,000 for a complete new system, compared to $100,000+ for traditional entry-level industrial machines. Used or refurbished options can be even cheaper.

Reduced Operating Costs (Potentially): Lower pressure systems often consume less power. Simpler pumps might have lower maintenance costs and fewer expensive seals to replace. Abrasive consumption per part is similar, but smaller machines might run fewer hours or cut thinner materials, using less overall.

Space Efficiency: Their compact footprint is ideal for smaller workshops or garages where space is a premium.

Ease of Use & Training: Many affordable models come with simplified, user-friendly CNC controls based on common platforms (like LinuxCNC or simplified proprietary interfaces), reducing the learning curve.

Faster ROI: The combination of lower upfront cost and the ability to take on profitable cutting jobs means businesses can potentially see a return on investment much quicker than with a high-end machine.

Material Savings: Nesting software allows efficient use of sheet material, minimizing waste – a significant saving, especially with expensive metals or stone. The thin kerf of the waterjet stream also contributes to material savings.

Cold Cutting: Eliminates HAZ, preserving material properties and structural integrity, crucial for metals and composites.

Versatility: One cheap water jet machine can replace several other cutting tools (saws, lasers for some materials, routers for hard materials), saving space and capital.

For the right user, these advantages make a cheap water jet machine an incredibly compelling tool.

4. Understanding the Limitations and Trade-Offs

Honesty is key. A cheap water jet machine isn’t a magic bullet and comes with inherent compromises:

Lower Cutting Speed & Thickness Capacity: This is the primary trade-off. Cutting harder, thicker materials (e.g., steel over 1/2″ thick) will be significantly slower than on a 60,000+ PSI machine. They are not suitable for cutting very thick metal plates (e.g., 6″ steel) efficiently or at all.

Potential for Reduced Precision & Repeatability: While good, the precision and long-term repeatability might not match the micron-level accuracy of top-tier industrial machines, especially over very large tables or after heavy prolonged use. Simpler linear motion systems (e.g., rack and pinion vs. ground ballscrews) can contribute.

Build Quality & Durability Concerns: Some budget machines may use lighter-duty components (frames, bearings, guides) to save costs. This can impact long-term durability, rigidity (affecting cut quality), and lifespan, especially under heavy daily use. Rigorous research is essential.

Limited Features: Expect basic functionality. Features like automatic abrasive metering, sophisticated height sensing, advanced cutting head technology (like dynamic XD), or large-capacity abrasive hoppers are often absent.

Support & Service: This is critical. Some manufacturers of very low-cost machines, particularly those imported directly, may have limited or non-existent local service and support networks. Downtime can be costly. Ensure spare parts availability and technical support accessibility.

Pump Maintenance: While potentially simpler, pumps still require regular maintenance. Understanding the maintenance schedule and costs for the specific pump type (direct drive vs. small intensifier) is vital.

Choosing a cheap water jet machine means carefully evaluating if its capabilities align with your specific needs and if you are comfortable with these trade-offs.

5. Navigating the Market: How to Find the Right Cheap Water Jet Machine

Finding a truly capable and reliable cheap water jet machine requires diligent research:

Define Your Needs: Be brutally honest. What materials (and max thicknesses) will you cut 90% of the time? What level of precision is actually required? What size parts? How many hours per day/week will it run? This defines the necessary specifications.

Research Reputable Brands: Look beyond just the lowest sticker price. Investigate manufacturers known for budget-friendly and reliable machines. Established industrial brands often have entry-level lines. Newer players focused on affordability can be good but vet them thoroughly. Consider brands like WARDJet (ECOs), OMAX (ProtoMAX, GlobalMAX), Axyz (Aquajet Lite), Shenyang Head, APW, or carefully vetted manufacturers from cost-competitive regions.

New vs. Used/Refurbished:

New: Warranty, latest tech, peace of mind. Higher initial cost. Explore entry-level models from reputable makers.

Used/Refurbished: Can offer significant savings on higher-capacity machines. Crucially requires expert inspection. Check pump hours, table wear, controller condition, and service history. Buy from reputable dealers offering refurbishment warranties.

Pressure is Paramount: 55,000 PSI offers significantly more capability than 40,000 PSI or direct drive (30,000 PSI or less). Prioritize the highest pressure your budget allows for greater material versatility and speed.

Component Quality: Inquire about the gantry construction (steel vs. aluminum), linear motion systems (ballscrews vs. rack & pinion), bearings, and guides. Heavier and more robust generally means better accuracy and longevity.

Software & Control: Ensure the CNC control is user-friendly and compatible with standard CAD/CAM software (or includes capable software). Good software is essential for efficient operation.

Support, Support, Support: This cannot be overstated. Where is the manufacturer/dealer located? What is their warranty? Do they have local technicians or a responsive remote support team? What is the cost and lead time for common spare parts (seals, orifices, mixing tubes)? Contact existing customers if possible.

Get Specific Quotes: Don’t just look at online ads. Contact suppliers with your specific requirements and get detailed quotes including machine, pump, control, basic accessories, shipping, installation, and initial training.

See it Run: If possible, visit a dealer or manufacturer for a demonstration. Ask them to cut materials similar to what you’ll be using.

The availability of genuinely capable cheap water jet machine options is a game-changer. It brings the unparalleled versatility and advantages of cold waterjet cutting within reach of a much broader audience. While compromises exist, primarily in speed on thick, hard materials and potentially long-term durability compared to top-tier machines, the benefits – affordability, compact size, material versatility, precision, and cold cutting – are transformative for countless applications.

Success hinges on thorough research and aligning the machine’s capabilities with your specific, realistic needs. Define your cutting requirements meticulously, prioritize build quality and manufacturer support alongside price, and understand the trade-offs involved. By carefully navigating the market, you can find a cheap water jet machine that isn’t just inexpensive, but a valuable and profitable asset to your workshop, enabling you to take on projects and materials you never thought possible without a massive capital investment. The power of waterjet cutting is now more accessible than ever.

continue reading

Related Posts

- 1216 words6.1 min read

- 1207 words6.1 min read