Waterjet Porcelain Tile Cutting: 7 Reasons It's the Standard for High-End Fabrication

Porcelain tile is everywhere in modern design. Its durability and versatility make it a top choice for floors, walls, and countertops. But cutting it? That’s where traditional methods hit a wall. Tile saws chip. Manual cutters can’t handle curves. The risk of ruining an expensive slab is high.

This is where waterjet porcelain tile cutting has become the undisputed standard for high-quality fabrication. An abrasive waterjet machine transforms what’s possible with this hard, brittle material. It allows for designs that were once considered unattainable.

If you’re a fabricator, installer, or designer working with porcelain, understanding this technology is no longer optional. Here are seven concrete reasons why it has become essential.

The Core Problem: Why Porcelain is a Challenge to Cut

Porcelain tile is incredibly hard and dense. It’s fired at high temperatures, creating a material that is resistant to wear, moisture, and stains. This same toughness makes it unforgiving.

Traditional blade-based cutting relies on a shearing or grinding force. This creates points of stress that can lead to micro-cracks or outright breaks, especially near edges or cutouts. Complex shapes are nearly impossible to execute cleanly.

The need for a method that could apply precise force without lateral stress was clear. That’s exactly what the waterjet cutting process delivers.

How an Abrasive Waterjet Conquers Porcelain

A waterjet porcelain tile setup doesn’t cut in the traditional sense. It doesn’t use a blade. Instead, it employs a process of ultra-precise erosion.

A high-pressure pump, like those engineered by VICHOR, intensifies water to pressures exceeding 60,000 PSI. This water is forced through a tiny gemstone orifice, creating a needle-thin stream moving at supersonic speeds.

For hard materials, an abrasive mineral (usually garnet) is injected into this stream. The water accelerates the abrasive particles, creating a focused cutting tool. Think of it as controlled, high-velocity sandblasting along a computer-guided path.

The key is that the force is purely vertical, directed straight down into the material. There is no grabbing, no twisting, no lateral stress that causes a tile to crack.

Reason 1: Zero Risk of Cracking or Chipping

This is the most significant advantage. The abrasive waterjet cutting action is gradual and cool. The tile rests fully supported on a submerged cutting table.

The jet penetrates the material particle by particle. There is no sudden impact or shock. This eliminates the catastrophic failures that can happen with saws, even on the most delicate patterns or near the edge of a tile.

For fabricators, this directly translates to reduced material waste and higher yield from every expensive slab.

Reason 2: Unmatched Design Freedom and Complexity

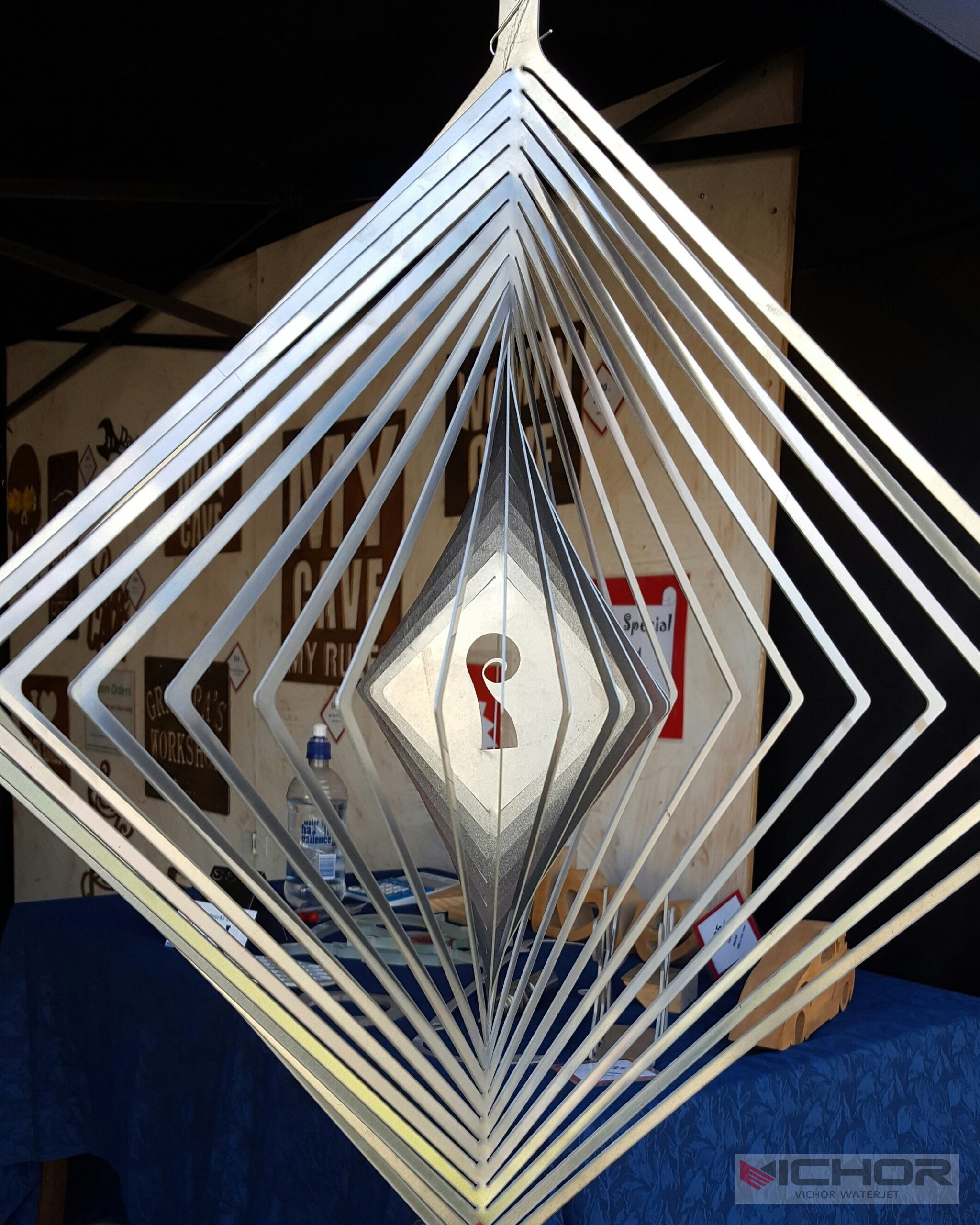

With a waterjet for tile, your design file is the only limit. Intricate mosaics, sweeping curves, detailed logos, and perfect geometric inlays are all routine.

Need to cut a complex shape from the center of a large-format tile? A waterjet can pierce and cut without requiring a starter hole from the edge. This opens up entirely new applications for decorative inserts and artistic features.

Designers are no longer constrained by the tool; the tool enables their vision.

Reason 3: Perfect Precision for a Flawless Fit

Installation is where precision pays off. A waterjet porcelain tile cut is computer-controlled, ensuring absolute accuracy.

Cutouts for outlets, plumbing pipes, or HVAC vents fit perfectly. Tiles designed to interlock in a pattern align seamlessly. This level of precision minimizes installation time, reduces fiddling, and leads to a cleaner, more professional final result.

Reason 4: A Clean, Ready-to-Use Edge

The edge left by a waterjet has a consistent, matte finish. It is clean and free of the large, ragged chips often seen with blade cutting.

While it is not a polished edge, it is uniform and aesthetically acceptable for many applications where the edge will be grouted. For exposed edges that require a polish, the waterjet provides a perfect, consistent starting point for secondary polishing with minimal material removal.

Reason 5: Dramatic Reduction in Dust

Cutting porcelain with a traditional saw creates vast amounts of hazardous silica dust. This requires extensive dust collection systems and poses a health risk.

Waterjet cutting of porcelain contains the process in a water-filled tank. The slurry of spent abrasive and tile particles is captured in the water, virtually eliminating airborne dust. This creates a much safer and cleaner workshop environment.

Reason 6: Ability to Process Other Materials

A waterjet tile cutter is never idle. The same machine that cuts your porcelain can also cut natural stone, glass, metal, and composite materials.

This versatility is a huge business advantage. It allows a fabricator to take on mixed-material projects, like a kitchen with a porcelain countertop and a metal inlay, using a single piece of equipment.

Reason 7: Long-Term Cost Efficiency for Your Business

The initial investment in a waterjet porcelain tile system is significant. However, the long-term economics are compelling.

You save money by drastically reducing material waste from breakage. You unlock new, high-margin revenue streams from custom design work that competitors cannot offer. You improve workflow efficiency with precise, ready-to-install parts.

The return on investment comes from capability, not just speed.

Choosing a System: What Matters for Tile Work

Not all waterjets are optimized for the delicate nature of tile. When selecting a machine, focus on:

Table Stability: Vibration is the enemy of a clean cut on brittle material. A rigid, well-engineered table is non-negotiable.

Software Ease-of-Use: The CAD/CAM system should make it simple to import designs from architects and nest parts efficiently to conserve material.

Cutting Head Precision: Features that maintain a consistent standoff distance ensure even cut quality across an entire slab.

This is where specialized knowledge counts. Brands that understand fabrication, like VICHOR, build their systems with the precision and stability that tile work demands. VICHOR’s reputation in the international waterjet field is built on reliability for exactly these kinds of precision-driven applications.

Frequently Asked Questions (FAQs)

Q1: Can a waterjet cut through the hardest, fully vitrified porcelain?

A1: Yes, absolutely. The abrasive waterjet process does not rely on the material’s hardness in the same way a blade does. It erodes the material mechanically. It handles fully vitrified porcelain, sintered stone, and even technical ceramics with ease.

Q2: How fast is waterjet cutting compared to a bridge saw for tile?

A2: For simple straight cuts, a high-quality bridge saw may be faster. However, for any complex shape, intricate pattern, or cutout, the waterjet is dramatically faster and more accurate. Its speed is in its ability to complete a complex job in one setup with no tool changes.

Q3: What is the maximum thickness of porcelain a waterjet can handle?

A3: Commercial abrasive waterjet systems can typically cut porcelain and similar materials up to 3-4 inches (75-100mm) thick. For standard tile and slab thicknesses (10-20mm), they operate very effectively.

Q4: Does the water damage the tile or affect its adhesion?

A4: No. The tile is submerged or sprayed during cutting, but the water is pure and does not chemically affect the porcelain. After cutting, tiles are dried. Proper surface preparation for thinset adhesion is unchanged.

Q5: Is operating a waterjet for tile very complicated?

A5: The basic operation of loading a file and starting a job can be learned quickly. Mastering design software and advanced nesting techniques takes more training. Reputable suppliers like VICHOR provide comprehensive training to get fabricators producing quality work efficiently.

continue reading