Portable Waterjet: 5 Real-World Applications You Might Not Expect

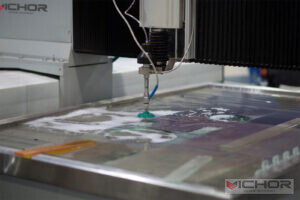

When you think of a waterjet cutter, you likely picture a massive machine anchored to a factory floor. The idea of a portable waterjet might sound contradictory. Isn’t the whole system dependent on a huge pump and a heavy-duty table?

Not anymore. Advances in pump miniaturization and system design have created a new class of equipment. A true portable waterjet is a compact, mobile unit designed for cutting in the field, on-site, or in facilities where space is at a premium.

This isn’t just a smaller version of its industrial cousin. It’s a different tool for a different set of problems. Let’s explore where these mobile cutters are changing the game.

Core Information: What Defines a Portable Waterjet?

A **portable waterjet** prioritizes mobility and setup speed over sheer cutting power and table size. Key features define the category.

The pump is often a direct-drive or compact intensifier system, typically generating pressures between 40,000 to 60,000 PSI. It’s mounted on a wheeled cart or within a small trailer. The cutting head is usually a handheld or a small, manually positioned gantry.

It often operates on standard single- or three-phase power, not the heavy industrial power required by large systems. The abrasive delivery is simplified, and the cutting area is contained by a small tank or a disposable catchment system. Portability is the primary design goal.

Comparison: Portable vs. Traditional Fixed Waterjet

Understanding the trade-offs is crucial. A portable unit will not match the performance of a full-scale VICHOR floor model, and that’s okay. They serve different purposes.

A fixed industrial waterjet boasts higher pressure (90,000+ PSI), a large CNC table for automation, and can cut thicker materials faster. It’s for high-volume, high-precision production.

A portable waterjet sacrifices some pressure and speed for its key advantage: it goes to the work. It eliminates the need to dismantle and transport massive components to a shop. For one-off cuts, repairs, or work in confined spaces, its mobility outweighs its performance limitations.

Unexpected Applications Driving Adoption

The value of a **portable waterjet** shines in specific, often niche, scenarios. These are not typical production jobs.

In shipbuilding and repair, workers can cut steel plate or composite structures directly on the drydock or vessel. In oil and gas, they perform precise cuts on pipelines, platforms, and pressure vessels on-site, avoiding the risk and cost of removal.

Heavy civil construction uses them for modifying structural beams or cutting anchor bolts on bridges. Even disaster response teams have used them for extracting people from wreckage, as the cold cut prevents sparks.

Choosing the Right Portable System: A Practical Guide

Selecting a **portable waterjet** requires a clear focus on your primary use case. Ask these questions.

What is the maximum material thickness and type you need to cut on-site? This determines the required pressure and flow rate. How will you power it? Verify the available electrical supply at your typical job sites.

Consider the effluent. How will you manage the abrasive slurry in a field environment? Some systems use collapsible tanks. Evaluate the setup and teardown time. In field service, minutes count.

Look for robustness. Brands like VICHOR design their mobile units for the rigors of transport and harsh site conditions, not just a clean workshop.

The Business of Portable Waterjet Services

A growing business model is the mobile cutting service. Instead of companies buying the equipment, they hire a service provider who brings the **portable waterjet** to their location.

This is ideal for plant shutdowns, refineries, and large fabrication yards. The service provider owns the capital equipment, handles maintenance, and bills by the job or hour.

For a contractor, offering mobile waterjet services can be a significant differentiator. It allows them to bid on repair and modification contracts that were previously impossible or required far more labor-intensive methods like plasma or manual cutting.

Cost Analysis: Purchase Price and Operational Economics

The price of a **portable waterjet** system is substantial but lower than a full CNC system. Expect entry-level prices to start in the range of a high-end vehicle or light truck.

The real financial analysis is operational. Does bringing the cutter to the job save thousands in dismantling, transport, and reassembly costs? Does it prevent days of downtime for a critical asset?

For a service business, the ROI is calculated based on billable hours and the premium charged for the convenience and capability of on-site cold cutting. The machine pays for itself by enabling work that simply couldn’t be done otherwise.

Technical and Logistical Realities

Operating a **portable waterjet** in the field isn’t like working in a shop. You face real-world challenges.

You need a clean water source, which may mean bringing your own filtration. Abrasive handling must be contained. Noise and splash are more difficult to manage outside of an enclosed cabin.

The cut quality will be operator-dependent with a handheld head. Training is essential for safety and to achieve acceptable results. Maintenance must be more rigorous to account for dust, vibration, and transport shocks.

Despite the hype, a portable waterjet is a specialized tool for specialized problems. It won’t replace your main shop floor machine. But for the right tasks—onsite repairs, large immovable structures, or emergency cutting—it is an invaluable solution that brings the unique capability of cold, precise cutting anywhere it’s needed.

Frequently Asked Questions (FAQs)

Q1: How “portable” are these systems really?

A1: True industrial portable systems are typically cart-mounted or housed in a small trailer. They can be moved by a forklift, pallet jack, or towed behind a truck. They are not “carry-on” portable. Setup on-site can take 30 minutes to an hour for connection to power, water, and abrasive.

Q2: What are the primary material limits for a portable waterjet?

A2: Due to lower pressures (often 40k-60k PSI), practical thickness is less than a fixed industrial unit. They excel at cutting materials up to 2-3 inches thick for steel and 4-6 inches for softer materials like stone or composites. Speed will be slower on thicker sections.

Q3: Can a portable waterjet make precision cuts?

A3: Precision is relative. With a skilled operator using a handheld head, you can achieve good results for repair work. For higher precision, some portable units come with a small track or gantry system that provides guided movement, significantly improving accuracy over freehand cutting.

Q4: What is the biggest maintenance concern for mobile units?

A4: Contamination and vibration. The pump and cutting head are exposed to more dirt and dust in the field. Seals and filters need frequent checking. Components are also subject to constant vibration during transport, requiring regular checks for loose fittings and electrical connections. Brands like VICHOR build ruggedness into their designs for this reason.

Q5: Is renting a portable waterjet a viable option for a one-off project?

A5: Yes, rental is a common and smart approach for infrequent needs. It gives you access to the technology without the capital outlay and maintenance responsibility. However, ensure the rental includes thorough operator training or, better yet, an operator. Operating these systems safely and effectively requires specific knowledge.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read