9 Essential Factors to Check Before You Find a Hydrojet Machine for Sale

Sourcing industrial cutting equipment is a massive commitment. When a workshop manager or business owner starts searching for a hydrojet machine for sale, the sheer volume of options can be overwhelming. From table sizes to pump pressures, the specifications vary wildly, and the price tags follow suit.

It is not just about finding the cheapest unit. It is about matching the machine’s capabilities to your production line. A stone fabricator needs a different setup than an aerospace parts manufacturer. The wrong choice leads to production bottlenecks and skyrocketing maintenance costs.

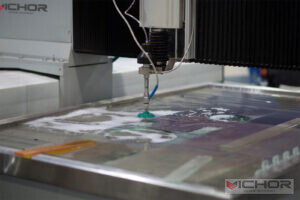

At VICHOR, we have seen how the right machine transforms a business. We also see what happens when buyers overlook critical technical details. This article cuts through the noise to help you understand what actually matters when evaluating waterjet listings.

The Core Technology: Abrasive vs. Pure Water

Before you even look at a price tag, you must define the cutting method. Most listings you will see are for abrasive waterjets. These mix garnet sand into the stream to erode hard materials like steel, titanium, and granite.

Pure waterjets, on the other hand, are designed for soft materials. They cut foam, rubber, paper, and food products. If you see a surprisingly cheap hydrojet machine for sale, check if it lacks an abrasive delivery system. If it does, it won’t cut metal.

Knowing your material list is step one. If you plan to cut 90% aluminum and 10% rubber, you need an abrasive machine with a “pure water only” mode. This versatility is standard in high-end models but missing in some entry-level units.

Evaluating Pump Pressure and Efficiency

The pump is the heart of the system. In the current market, you will generally encounter two pressure standards: 60,000 PSI (4,100 bar) and roughly 90,000 PSI (6,200 bar). This difference changes everything regarding speed and operating cost.

A machine rated for 60k PSI is the industry workhorse. It is reliable, parts are widely available, and maintenance is straightforward. For general job shops, this is often the sweet spot.

However, if you are looking at a hydrojet machine for sale that boasts 90k PSI, you are looking at a performance beast. These pumps cut 30-50% faster on thick materials. The trade-off is seal life. Higher pressure wears down components faster, meaning more frequent maintenance intervals.

Direct Drive vs. Intensifier Pumps

When browsing listings, you will see “Direct Drive” and “Intensifier” referenced constantly. Direct drive pumps work like a pressure washer engine. They are incredibly energy-efficient, transferring over 90% of motor power to the water.

Intensifier pumps use hydraulics to move a plunger. They are less energy-efficient but are legendary for their durability and ability to maintain ultra-high pressure for long cycles. If your shop runs 24/7, an intensifier is often the preferred choice.

Make sure the seller specifies the pump type. A direct drive is often cheaper upfront and saves on electricity, making it attractive for smaller shops. An intensifier is built for the long haul of heavy industrial use.

Table Size and Gantry Construction

The physical footprint of the machine dictates what jobs you can accept. A standard 5×10 foot table covers most sheet metal work. However, oversized tables are becoming more common for architectural and marine applications.

Inspect the gantry construction. A hydrojet machine for sale with a flimsy aluminum rail system will suffer from vibration. Vibration leads to poor edge quality (striations) on the cut parts.

Look for heavy-duty steel gantries or castings. Brands like VICHOR prioritize rigidity because it directly correlates to accuracy. If the machine shakes when the cutting head changes direction rapidly, your tolerances are gone.

Motion Control and 5-Axis Capabilities

Standard cutting is 3-axis (X, Y, and Z). This cuts flat parts effectively. But the modern market often demands more. Beveled edges, countersinks, and complex 3D shapes require 5-axis capability.

More importantly, 5-axis heads offer “Taper Control.” Waterjets naturally cut in a V-shape. A 5-axis head tilts the nozzle to compensate, ensuring the part edge is perfectly square. If you are making precision machine parts, taper control is not optional; it is mandatory.

When you find a hydrojet machine for sale, ask if it is “5-axis ready.” Some machines come with 3-axis heads but have the controller capacity to upgrade later. This is a good middle ground for growing businesses.

Software: The Overlooked Component

You can have the best iron in the world, but if the software is difficult to use, productivity tanks. The controller should be intuitive. Operators need to import DXF or DWG files and set up cut paths in minutes.

Nesting software is another critical factor. Good software arranges parts on the sheet to minimize waste. With material prices rising, saving 10% on raw material usage goes directly to your bottom line.

Ask the seller for a demo of the control software. Is it proprietary? Is it Windows-based? Can you hire operators who already know it, or will you need extensive training?

Abrasive Delivery and Management

Abrasive garnet is your biggest ongoing expense. A good machine needs a reliable bulk feed system. Loading 50lb bags by hand into a small hopper every hour is a waste of labor.

Look for a bulk hopper system that holds 500lbs or 2000lbs of garnet. This allows for unmanned running. Additionally, check the abrasive metering system. It needs to be precise. Too much abrasive clogs the nozzle; too little slows the cut.

Also, consider waste removal. Where does the used sludge go? Advanced systems have abrasive removal units that pump the sludge out of the tank automatically. If the hydrojet machine for sale you are eyeing lacks this, prepare to shovel out the tank manually every few weeks—a dirty and downtime-heavy job.

Understanding Total Cost of Ownership (TCO)

The sticker price is just the entry fee. The real cost is in operation. You need to calculate the cost per hour. This includes electricity, water, garnet, wear parts (nozzles, orifices, seals), and labor.

A cheap machine often consumes more abrasive to do the same job as a tuned, high-end machine. If a machine saves you $20,000 upfront but costs $10 more per hour to run, you will lose money in the long run if you are busy.

At VICHOR, we advise clients to look at the “cost per part” rather than just the machine price. High-quality components last longer, reducing the frequency of expensive rebuilds.

Water Quality and Filtration

Water is the cutting tool, so its chemistry matters. Hard water destroys high-pressure seals. Dissolved solids act like microscopic sandpaper inside the pump.

Does the listing include a water softener or a Reverse Osmosis (RO) system? If not, you may need to budget for one. Feeding tap water directly into a 90k PSI pump is a recipe for maintenance headaches.

Check the manufacturer’s water specifications. If your local water supply is poor, the machine’s warranty might be void without proper filtration equipment.

Installation and Training Support

Installing a waterjet is not “plug and play.” It requires high-voltage electrical hookups, pneumatic lines, water drainage, and precise leveling. Who handles this?

If you are buying a used hydrojet machine for sale from an auction, you are on your own. If you buy from a reputable manufacturer or dealer, installation is usually included.

Training is equally vital. Waterjet physics are unique. Operators need to understand piercing techniques for brittle materials, how to handle “lag” in the stream, and how to maintain the pump. Ensure training is part of the package.

The VICHOR Advantage

In the crowded market of cutting solutions, brand reputation holds weight. VICHOR has established itself by focusing on the balance between durability and innovation. We don’t just assemble parts; we engineer solutions for longevity.

Our machines are designed with the operator in mind. From easy-access maintenance panels to software that simplifies complex cuts, we address the pain points of daily fabrication.

When you see a VICHOR machine, you are looking at a system built for international standards, capable of handling the rigors of heavy industry while maintaining the precision required for delicate architectural work.

Environment and Safety Considerations

Waterjet cutting is cleaner than plasma or laser. There are no toxic fumes or heat-affected zones (HAZ). However, it is loud. The supersonic stream breaking the sound barrier creates significant noise.

Check if the machine allows for submerged cutting. Cutting underwater drastically reduces noise and keeps the shop cleaner by trapping spray. This is a feature worth paying for if your shop is small or has strict noise regulations.

Inspection Checklist for Used Machines

If you decide to buy used, proceed with caution. Here is a quick checklist:

- Hour Meter: Check “pump on” hours vs. “cutting” hours.

- High-Pressure Cylinders: Look for hairline cracks. These are expensive to replace.

- Ball Screws: Check for backlash or play in the motion system.

- Controller: Is it obsolete? Can you still get boards for it?

- Tank Condition: Is the slat support structure rusted out?

Finding the right hydrojet machine for sale requires a mix of technical knowledge and financial foresight. It is an investment that can open doors to aerospace, medical, and energy sectors if chosen correctly.

Don’t rush the process. Evaluate the pump technology, the software ecosystem, and the support structure behind the metal. Whether you are cutting 6-inch titanium or delicate glass inlays, the right machine is out there.

For those seeking a partner rather than just a vendor, explore what VICHOR brings to the table. Quality cutting starts with quality equipment.

Frequently Asked Questions

continue reading

Related Posts

- 1315 words6.6 min read

- 1300 words6.6 min read

- 1232 words6.2 min read