6 Surprising Benefits of Ordering Waterjet Cutting Online

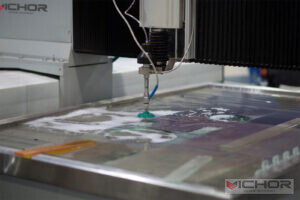

The way we manufacture prototypes and parts is changing. You no longer need to own a machine or even visit a local shop. Online waterjet cutting has turned a powerful industrial process into a service you can order from your desk. It’s simpler than you think.

This model connects customers with specialized facilities through digital platforms. You upload a design, get an instant quote, and receive precision-cut parts at your door. It’s revolutionizing access to this versatile technology.

For engineers, designers, and small businesses, online waterjet service removes traditional barriers. There’s no need for large capital investment or machining knowledge. This article explains how it works and why it might be your new best tool.

How Does an Online Waterjet Service Actually Work?

The process is streamlined and user-friendly. It’s designed for efficiency, not complexity. Most platforms follow a similar, intuitive path.

First, you visit the service provider’s website. Companies like VICHOR offer dedicated portals for this. You start by uploading your CAD file. Common formats like DXF, DWG, or STEP are typically accepted.

The platform’s software then analyzes your design. It calculates the cut path, material required, and cutting time. Within minutes, you receive an interactive price quote. You can often adjust material type, thickness, and quantity to see how it affects the cost instantly.

Once you approve, the file is queued for production at a professional facility. Your parts are cut, inspected, and shipped directly to you. The entire transaction happens online.

The Materials and Applications Perfect for Online Orders

A key advantage of online waterjet cutting is material access. These services stock a vast array of materials you might not easily source yourself.

Common orders include metals like aluminum, stainless steel, brass, and titanium. But it doesn’t stop there. Plastic sheets, rubber, stone, tile, and composites like carbon fiber are also standard.

Typical applications are perfect for this model. Prototyping is a major one. You can iterate a design quickly without tooling costs. Art and architectural features, machine parts, gaskets, and signage are all frequently ordered.

The online waterjet cut service is ideal for low to medium volume production runs. It fills the gap between one-off prototypes and mass production requiring dedicated tooling.

Cost Transparency: Understanding Your Quote

Pricing in online waterjet cutting is usually clear and itemized. You’re not getting a mysterious estimate. You see the cost drivers.

The quote is based on several factors. Material type and cost per square foot is the first component. Thickness is critical, as cutting time increases with it.

The total cutting length or “cut time” is the core of the price. Complex designs with many intricate details take longer than simple shapes. Setup charges and any required finishing, like deburring, are added.

The best platforms have a real-time quoting engine. This transparency allows for cost engineering before you order. You can simplify a design to save money immediately.

File Preparation: Getting Your Design Ready

A smooth online waterjet cutting experience depends on your file. Proper preparation prevents delays and ensures you get exactly what you envision.

Ensure your file is a clean, vector-based outline. Remove any construction lines, text, or unnecessary layers. The software will cut every line it sees.

Consider the kerf—the tiny width of material removed by the stream. Reputable services will automatically compensate for this, but it’s good to know. Specify critical dimensions clearly if needed.

For multiple parts, nest them efficiently within your file to minimize material waste. Some advanced online quoting for waterjet platforms even offer automated nesting tools to help you save.

Speed and Lead Time from Click to Delivery

One of the most compelling benefits is speed. Ordering waterjet cutting online bypasses traditional quoting delays.

The instant quote is the first time-saver. Approval and payment are digital. Your job enters a production schedule immediately, often within 24 hours.

Standard lead times for online waterjet cut parts can range from 3 to 7 business days, depending on complexity and queue. This is far faster than most traditional machine shops can quote, let alone produce.

For true emergencies, many services like VICHOR offer expedited options. While it costs more, the ability to get critical parts in days is a game-changer for project timelines.

Quality Assurance and Consistency

A legitimate concern is quality. How can you trust parts you ordered over the internet? Professional online waterjet cutting services stake their reputation on consistency.

These are not hobbyist machines. They use industrial-grade, high-pressure pumps (like those from VICHOR) and precision CNC tables. The process is automated and repeatable.

Detailed order specifications lock in the requirements. Reputable providers include basic quality checks, measuring critical dimensions on sample parts. They handle the material professionally to prevent scratches or damage.

You are leveraging their expertise and investment in top-tier equipment. The result is often higher quality than what might be achieved on an older, less maintained machine in a local shop.

When to Choose an Online Service Over a Local Shop

The online waterjet cutting solution isn’t for every single job, but it fits most scenarios perfectly. It excels in specific situations.

Choose online when you need a wide variety of materials. When speed of quoting and order placement is critical. When your local options are limited or lack capacity.

It’s superior for one-off projects and short runs where building a relationship with a local shop isn’t as efficient. The digital workflow provides a clear audit trail of your order, files, and communications.

For businesses without a dedicated procurement person, the self-service model of an online waterjet service is empowering and efficient. You control the entire process.

Frequently Asked Questions (FAQs)

Q1: What file formats do I need for online waterjet cutting?

A1: Most services accept standard 2D vector formats. DXF and DWG are the most common and preferred. Some also accept AI, PDF, or STEP files. Always check your chosen provider’s specifications. Ensure your file uses actual dimensions and that all lines are connected (closed vectors).

Q2: Is there a minimum order quantity or cost?

A2: Typically, yes. Due to setup and handling, most online waterjet cutting services have a minimum order charge. This can range from $50 to $150. It makes small, simple parts affordable while ensuring the service remains viable for the provider.

Q3: How accurate are the parts from an online service?

A3: Professional services deliver high accuracy. Standard tolerances of ±0.005″ (±0.13 mm) are achievable on most materials and thicknesses. For critical features, you can often specify tighter tolerances, though this may affect the quote and lead time.

Q4: How do I pay for an online waterjet order?

A4: Payments are processed securely through the online platform, just like any e-commerce site. Major credit cards are standard. For large corporate accounts, some providers like VICHOR may also offer net-term invoicing after establishing a relationship.

Q5: Who owns the design file I upload?

A5: You retain full intellectual property (IP) ownership of your design. Reputable online waterjet cutting providers have strict data security and confidentiality policies. Your file is used solely to produce your order and is not shared or used for any other purpose. Always review the service’s terms and conditions.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read