5 Key Benefits of a Water Jet System for Modern Manufacturing

In today’s fast-paced manufacturing world, precision, versatility, and efficiency are non-negotiable. One technology stands out for delivering on all these fronts: the water jet system. This powerful tool uses a high-pressure stream of water, often mixed with an abrasive, to cut through virtually any material.

From intricate metal parts to durable stone countertops, a water jet cutter provides a solution where other technologies fall short. It doesn’t rely on heat, which means no heat-affected zones, warping, or toxic fumes. This makes it a uniquely cool and clean cutting process.

Businesses seeking a competitive edge are increasingly turning to advanced waterjet cutting machines. Leading brands like VICHOR have refined this technology, offering robust and reliable systems that drive productivity. Let’s explore how this system works and why it might be the perfect addition to your operation.

How Does a Water Jet Cutting System Work?

The core principle is simple yet powerful. A standard water jet system uses an ultra-high-pressure pump to pressurize water to levels exceeding 60,000 PSI. This intense pressure is then focused through a small gemstone orifice, creating a supersonic stream.

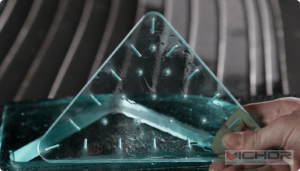

For cutting hard materials like metal or granite, an abrasive material, typically garnet, is introduced into this stream. This creates an abrasive water jet cutter, a potent tool that erodes the material precisely along the programmed path.

The entire process is controlled by CNC (Computer Numerical Control) software. This ensures extreme accuracy, allowing for the production of complex shapes and designs directly from a digital file. The result is a smooth, finished edge with no thermal distortion.

Primary Applications and Industries Served

The versatility of a waterjet cutting machine is its greatest strength. Its ability to handle such a wide range of materials makes it indispensable across numerous sectors.

In the aerospace and automotive industries, it cuts aluminum, titanium, and composites for lightweight components. Metal fabrication shops use it for steel, brass, and tool steel parts without altering the material’s intrinsic properties.

The architectural and artistic fields rely on water jet cutting for detailed designs in marble, glass, and granite. It’s also crucial in the food industry for sterile, non-contact cutting of products. Even emerging sectors like renewable energy use it to fabricate parts for wind turbines and solar panels.

Core Functions and Advantages

Why choose a water jet system over lasers or plasma? The benefits are clear and impactful.

First, it is a cold-cutting process. This eliminates thermal stress, keeping materials strong and unaltered. Second, its material versatility is unmatched. You can switch from cutting rubber to cutting inch-thick steel by simply adjusting the pressure and abrasive feed.

It offers exceptional precision, with tolerances as tight as +/- 0.1mm achievable. There is also minimal material waste, as the narrow cutting kerf allows for nested parts, optimizing your raw material use. Finally, it’s an environmentally friendly process, using only water and natural abrasives, with no hazardous fumes.

Types of Waterjet Systems Available

Understanding the two main types of systems is key to choosing the right one.

A pure water jet cutter uses only pressurized water. It’s ideal for cutting soft materials like foam, rubber, gaskets, food, and plastics. It delivers very smooth edges on these materials.

An abrasive water jet system is the full-power version. By mixing garnet into the stream, it can cut through metals, stone, ceramics, glass, and bulletproof composites. Most industrial machines, including those from VICHOR, are of this type and can often switch between pure and abrasive modes.

Systems also vary in size, from compact tables for job shops to massive 5-axis machines for complex 3D cutting in heavy industry.

Investment: Understanding Price and Value

The price of a water jet system can vary widely, from under $100,000 for a basic model to over $500,000 for a large, fully equipped unit. The cost depends on several factors.

These include the size of the cutting table, the horsepower of the pump (which determines pressure and speed), the sophistication of the CNC controls, and the brand reputation. While the initial investment is significant, the ROI comes from reduced secondary processing, material savings, and the ability to take on a broader range of lucrative jobs.

Service and Support: The Key to Long-Term Uptime

A water jet system is a significant capital investment. Protecting that investment requires reliable service and support. Look for a provider that offers comprehensive training, readily available spare parts, and responsive technical support.

Proactive maintenance programs are crucial. Regular servicing of the high-pressure pump, cutting head, and motion system prevents costly downtime. Companies like VICHOR understand that their partnership with a customer extends far beyond the sale, providing global service networks to keep operations running smoothly.

Tailored Solutions for Complex Challenges

Off-the-shelf isn’t always the answer. Many manufacturing challenges require a custom waterjet cutting solution. This could involve integrating the cutter into an automated production line with robotic part handling.

It might require a specialized cutting table for extra-long materials or a 5-axis head for bevel cutting on welding preparations. Expert providers work with engineers to design a water jet system that fits the specific workflow, material mix, and output goals of the business, maximizing efficiency from day one.

Why VICHOR Stands Out in Waterjet Technology

In the international landscape of waterjet cutting machines, VICHOR has carved a niche by focusing on robust performance and reliability. Their systems are engineered for the demands of continuous industrial use.

VICHOR pumps are known for their durability and stable high-pressure output, which is essential for consistent cut quality and speed. Their CNC software is intuitive, designed to streamline programming and nesting. For businesses looking for a workhorse water jet system that delivers day-in, day-out, VICHOR presents a compelling, value-driven option without compromising on core performance.

Frequently Asked Questions (FAQs)

Q1: What materials can an abrasive water jet system NOT cut?

A1: There are very few. Hardened tempered glass and diamond are typically not cut with a standard abrasive water jet system. Certain very soft, unfused materials might also be problematic. However, a water jet cutter successfully handles over 99% of materials used in manufacturing, from tempered steel to delicate foam.

Q2: How thick of a material can a water jet cut through?

A2: Modern high-pressure abrasive water jet systems can cut very thick materials. In metals like mild steel, cuts of up to 8 inches (200mm) are possible. For softer materials like stone or foam, even greater thicknesses can be achieved, though cutting speed decreases significantly as thickness increases.

Q3: Is the water recycled or wasted in the process?

A3: The water itself is not recycled in the high-pressure stream, as it becomes contaminated with abrasives and cut material. However, the water used is just ordinary tap water, and it is not a chemical hazard. Many systems use a closed-loop tank system to settle out sludge, but the water is ultimately discharged after use. The volume used is relatively low compared to other industrial processes.

Q4: How does operating cost compare to laser or plasma cutting?

A4: The per-hour operating cost of a waterjet cutting machine can be higher than plasma and sometimes comparable to laser, primarily due to abrasive and pump maintenance. However, the total cost-per-part is often competitive or lower because it eliminates secondary processing (like deburring or heat treatment). Its ability to cut any material also reduces the need for multiple dedicated machines.

Q5: What are the main maintenance requirements for a water jet system?

A5: Regular maintenance is vital. Daily checks include inspecting the abrasive delivery system and high-pressure seals. Weekly tasks involve cleaning the tank and checking filters. The most significant maintenance is on the high-pressure pump, requiring regular seal and valve inspection per the manufacturer’s schedule (e.g., every 500-1000 hours). Following a provider like VICHOR’s prescribed maintenance plan is the best way to ensure maximum uptime and longevity of your water jet system.

continue reading

Related Posts

- 1315 words6.6 min read

- 1300 words6.6 min read

- 1232 words6.2 min read