Waterjet Cutting Food: How This Technology is Reshaping What We Eat

Imagine slicing a birthday cake into perfect, intricate shapes without a single crumb out of place. Or dividing a multi-layered dessert with such precision that every portion is identical. This isn’t the work of a master pastry chef with a steady hand, but the everyday capability of waterjet cutting food technology. Far from the industrial workshops it’s often associated with, the waterjet food cutting process is making waves in kitchens and production facilities around the globe. It’s a method that uses a high-pressure stream of water to slice through edible items with an accuracy that traditional blades simply cannot match. For anyone in the food industry—from large-scale manufacturers to artisanal creators—understanding this technology is becoming increasingly important. This article delves into the world of waterjet cutting food, exploring its mechanics, advantages, and the practical considerations for implementing it in your operations.

What Exactly is Waterjet Cutting in the Food Industry?

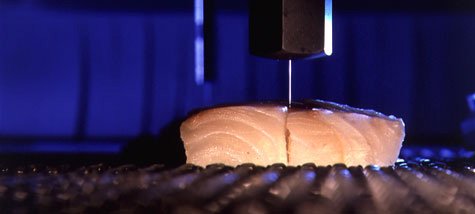

At its core, **waterjet cutting food** involves using a pump to pressurize water to extreme levels, often between 50,000 to 90,000 psi, and then forcing it through a tiny nozzle made of sapphire or diamond. This creates a supersonic stream of water that acts like an incredibly fine, powerful blade. In the context of food, this process is almost always “pure,” meaning no abrasives are added to the water stream. The result is a cutting tool that can handle a vast array of food items, from soft baked goods to frozen meats and delicate fish fillets, without contaminating the product. The system is typically guided by computer numerical control (CNC), which follows a digital design to execute cuts with remarkable consistency. This marriage of high-pressure hydraulics and precision engineering is what makes **waterjet food cutting** a game-changer for portion control, decorative design, and production efficiency.

Why Waterjet Cutting Outperforms Traditional Food Slicing Methods

When stacked against conventional methods like band saws, guillotine cutters, or manual knives, the benefits of **waterjet cutting food** become clear. Traditional blades often crush, tear, or compress cellular structures, leading to unsightly bruising on fruits, smashed pastries, or ragged edges on meat. The **waterjet food cutter** applies minimal lateral force, performing a “cold cut” that preserves the integrity of the most delicate items. For products with multiple layers, such as sheet cakes with frosting, a waterjet can slice through without causing layers to shift or separate. Furthermore, the hygiene aspect is superior. A **waterjet cutting food** system is easily sanitized and presents no nooks or crannies for bacteria to thrive, unlike complex mechanical blades. This method also drastically reduces cross-contamination risks, as the water is typically filtered and often sterilized, providing a continuous cleaning action during the cut itself.

The Expanding Menu: Common and Creative Applications

The versatility of **waterjet cutting food** is seen in its wide range of applications across the food sector. In large-scale bakeries, it’s used to portion massive sheets of cake, brownies, and bars with pinpoint accuracy, minimizing waste and ensuring every product meets weight specifications. Pizzerias and producers use it to slice frozen pizzas cleanly, without dragging cheese or toppings. The seafood industry relies on **waterjet food cutting** to portion fish fillets and even shuck shellfish with unparalleled precision. Perhaps the most visually striking applications are in the realm of creative food design. Intricate patterns can be cut into fruit leather, detailed shapes can be carved from sheets of cheesecake, and personalized messages can be etched onto large cookies. The technology allows for the mass customization of food products, enabling brands to offer unique, visually appealing items that were previously impossible or too labor-intensive to produce.

Selecting a System for Food Waterjet Cutting

Choosing the right **waterjet food cutter** requires careful consideration of several factors. The first is throughput; determining the volume of product you need to process per hour will guide you toward either a simpler 2-axis system or a more complex multi-axis setup for higher automation. The type of food you primarily work with is another critical factor. Softer, more porous items might require lower pressure, while frozen or harder foods will need the full power of the pump. The cutting area, or the size of the bed, must accommodate your typical product dimensions. Hygiene should be a top priority, so look for systems with food-grade components, easy-clean surfaces, and compatible water filtration or disinfection systems like UV or ozone. Finally, consider the software interface—it should be user-friendly enough for your operators to create and modify cutting paths without extensive training.

Navigating Costs and Finding the Right Supplier

The investment in a **waterjet cutting food** system is significant, with entry-level machines starting around $60,000 and high-capacity, automated lines running into the hundreds of thousands. Beyond the initial purchase price, operational costs include electricity, water filtration, pump maintenance, and replacement parts for wear items like the nozzle and high-pressure seals. However, this cost is often offset by the dramatic reduction in product waste. By optimizing cutting patterns, a **waterjet food cutting** system can maximize yield from expensive ingredients like premium meat or salmon, paying for itself over time. When searching for suppliers, focus on companies with a proven track record in the food industry. They should understand the strict hygiene standards and be able to provide references from other food producers. Requesting a sample cutting session with your own products is a crucial step in the evaluation process.

The Technical Side: How the Cutting Process Works with Food

The science behind **waterjet cutting food** is a fascinating blend of physics and engineering. The process begins with ordinary tap water, which is first intensely filtered and often sterilized. This pure water is then sent to an intensifier pump, which uses hydraulic power to amplify the water pressure to these extreme levels. The high-pressure water is then delivered through specialized tubing to the cutting head. As the water accelerates through the tiny orifice of the nozzle, its velocity can exceed three times the speed of sound. This hyper-fast, thin stream (typically about 0.004 to 0.010 inches in diameter) shears through the food product with minimal kerf (the width of the cut). Because the process is controlled by a computer, it can execute incredibly complex patterns with tolerances as tight as a few thousandths of an inch, ensuring every cut is a perfect replica of the last.

Frequently Asked Questions About Waterjet Cutting Food

Q1: Is the food safe to eat after being cut with a waterjet?

A1: Absolutely. The waterjet cutting food process uses high-quality, filtered, and often sterilized water. Since no abrasives are used in food applications, the only substance touching the food is pure water, making it completely safe for consumption.

Q2: Doesn’t the water make the food soggy?

A2: Surprisingly, no. The stream is so fine and moving at such a high velocity that it makes a clean cut with very little water penetration. For most products, the amount of water added is negligible and does not affect the texture or quality of the food.

Q3: What kinds of food cannot be cut with a waterjet?

A3: While the range is vast, very dry, powdery items like flour or certain brittle spices can be challenging, as the water stream can cause dispersion. Items with a loose, crumbly structure might also not hold up well during the process without proper support.

Q4: How do you maintain hygiene and prevent bacterial growth in the system?

A4: Modern waterjet food cutting systems are designed with sanitation in mind. They use food-grade materials, are easy to disassemble and clean, and often incorporate in-line water sterilization methods such as UV light or ozone to ensure the water remains pure and free from pathogens during operation.

Q5: Can a waterjet cutter handle frozen foods?

A5: Yes, this is one of its standout strengths. Waterjet food cutting is exceptionally effective on frozen products, including meat, pizza, and seafood. It can slice through them cleanly without the cracking or shattering that can occur with traditional saws, and it doesn’t create the heat that leads to partial thawing and quality loss.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read