Pure Water Jet: Transforming Industries with High-Pressure Precision

In today’s rapidly evolving industrial landscape, the quest for efficient, precise, and environmentally friendly technologies has led to the rise of the pure water jet. This innovative method harnesses the power of water at extremely high pressures to cut, clean, and process materials with unparalleled accuracy. Unlike traditional methods that rely on heat or mechanical force, a pure water jet uses only water, making it a versatile tool across various sectors. From manufacturing to healthcare, the applications of pure water jet systems are expanding, driven by their ability to deliver clean, burr-free cuts without altering material properties. In this article, we will delve into the fundamentals, mechanisms, applications, benefits, and future prospects of pure water jet technology, providing a comprehensive overview for anyone interested in this cutting-edge approach. By understanding how a pure water jet works and where it excels, businesses and individuals can make informed decisions about integrating this technology into their operations.

What is a Pure Water Jet?

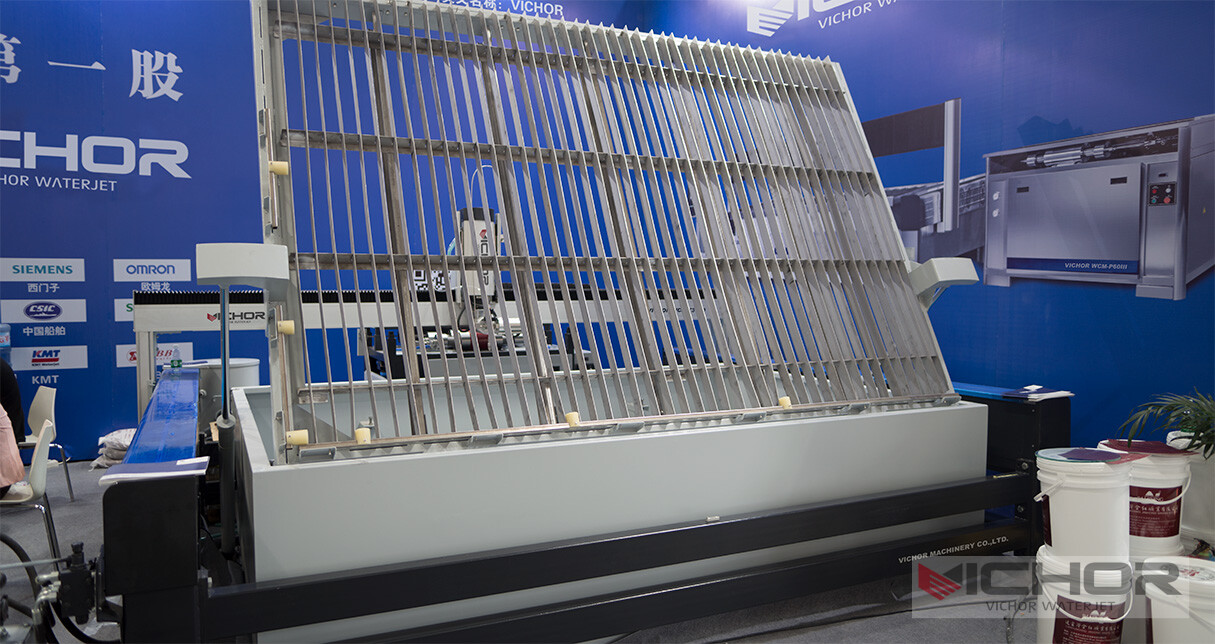

A pure water jet is a technology that utilizes a focused stream of water pressurized to extremely high levels—often exceeding 60,000 psi—to perform cutting, cleaning, or surface preparation tasks. This system relies solely on water, without the addition of abrasives, which distinguishes it from abrasive water jets. The concept dates back to the mid-20th century when researchers discovered that water under high pressure could cut through soft materials like paper and food. Over time, advancements in pump technology and nozzle design have enabled pure water jets to handle a wider range of materials, including plastics, rubber, and foams. The core components of a pure water jet system include a high-pressure pump, an intensifier to amplify pressure, a nozzle to direct the stream, and a catcher tank to manage wastewater. This setup ensures that the pure water jet operates efficiently, minimizing energy consumption and environmental impact. By focusing on water alone, this method reduces operational costs and simplifies maintenance, making it an attractive option for industries seeking sustainable solutions. The purity of the water used is crucial, as contaminants can affect performance, so filtration systems are often integrated to maintain consistency. Overall, a pure water jet represents a leap forward in non-thermal, non-contact processing, offering a safe and precise alternative to conventional methods.

How Does a Pure Water Jet System Work?

The operation of a pure water jet system begins with a high-pressure pump that pressurizes water to levels typically ranging from 30,000 to 90,000 psi. This pressurized water is then forced through a small orifice in the nozzle, creating a supersonic stream that can reach speeds of up to 2,500 feet per second. The intense velocity and pressure allow the pure water jet to erode and cut through materials with remarkable precision. Key to this process is the laminar flow of the water stream, which ensures a consistent and focused cut without splashing or dispersion. The nozzle design plays a critical role in maintaining this flow, often featuring diamond or sapphire orifices for durability and accuracy. In applications where cutting harder materials is required, some systems may switch to abrasive modes, but the pure water jet variant strictly uses water, making it ideal for softer substances. Control systems, often computer-numerical-controlled (CNC), guide the nozzle along predefined paths, enabling complex shapes and patterns to be cut with tolerances as tight as 0.005 inches. The wastewater generated is typically collected and recycled, emphasizing the eco-friendly nature of the technology. This mechanism not only ensures minimal heat-affected zones but also reduces the risk of material distortion, which is common in laser or plasma cutting. By leveraging the natural properties of water, a pure water jet system provides a clean, efficient, and versatile solution for various industrial tasks, from intricate designs in packaging to precise cuts in automotive interiors.

Applications of Pure Water Jet in Modern Industries

The versatility of the pure water jet has led to its adoption across a wide array of industries. In the food sector, for example, it is used for slicing fruits, vegetables, and baked goods without crushing or contaminating the products, thanks to its sterile and gentle approach. The automotive industry employs pure water jet systems for cutting interior components like dashboards, gaskets, and insulation materials, where precision and lack of thermal damage are crucial. In aerospace, this technology is valued for trimming composite materials and plastics used in aircraft interiors, ensuring lightweight and durable parts. The textile and apparel industries benefit from pure water jet cutting for fabrics and leather, as it prevents fraying and allows for intricate patterns. Additionally, the electronics sector uses pure water jets to cut circuit boards and sensitive components without generating static electricity or debris. Beyond manufacturing, pure water jet systems are increasingly used in cleaning applications, such as removing coatings from surfaces or decontaminating equipment in pharmaceutical settings. The medical field also explores pure water jets for tissue dissection in surgeries, where minimal invasion is essential. This broad applicability stems from the ability of a pure water jet to handle diverse materials without introducing chemicals or heat, making it a go-to solution for industries prioritizing quality, safety, and environmental sustainability. As technology advances, new applications continue to emerge, further solidifying the role of pure water jet systems in modern production and maintenance processes.

Advantages of Using Pure Water Jet Technology

One of the primary advantages of a pure water jet is its environmental friendliness, as it uses only water and produces no hazardous waste or emissions. This aligns with global sustainability goals and reduces disposal costs compared to methods involving chemicals or abrasives. Another significant benefit is the precision offered by a pure water jet, which allows for clean, sharp cuts with minimal kerf width, reducing material waste and improving efficiency. Since the process is non-thermal, it eliminates heat-affected zones, preserving the intrinsic properties of materials like plastics or composites that might warp or melt under high temperatures. Safety is also enhanced, as there is no risk of fire or fumes, making pure water jet systems suitable for volatile environments. Operationally, these systems are highly versatile and can be easily integrated with automation, leading to faster production times and lower labor costs. Maintenance is straightforward because the absence of abrasives means less wear on components, extending the lifespan of the equipment. Moreover, the pure water jet method supports a wide range of material thicknesses and types, from thin films to dense foams, without requiring tool changes. This flexibility translates to cost savings and increased productivity for businesses. Overall, the combination of eco-efficiency, precision, and adaptability makes the pure water jet an invaluable asset in industries aiming for high-quality outputs while minimizing their ecological footprint.

Challenges and Limitations of Pure Water Jet Systems

Despite its many benefits, the pure water jet technology does face certain challenges. One limitation is its inability to effectively cut hard materials like metals or ceramics without switching to an abrasive-assisted mode, which defeats the purpose of a pure water jet. This restricts its use primarily to softer materials, potentially requiring additional equipment for diverse applications. Another issue is the high initial investment cost, as pure water jet systems involve sophisticated pumps and controls that can be expensive to purchase and install. Operating costs can also be significant due to the energy required to maintain high pressures and the need for ultra-pure water to prevent nozzle clogging and damage. Maintenance, while generally simpler than abrasive systems, still demands regular checks on seals and orifices to ensure optimal performance. Noise levels during operation can be high, necessitating hearing protection in industrial settings. Additionally, the wastewater generated, though often recyclable, must be properly managed to avoid environmental contamination. In terms of speed, pure water jets may be slower than other cutting methods for certain materials, which could impact throughput in high-volume production. However, ongoing research aims to address these limitations through innovations in pump efficiency, nozzle materials, and control software. By understanding these challenges, users can better plan for integrating pure water jet systems and leverage their strengths while mitigating drawbacks.

The Future of Pure Water Jet Technology

The future of pure water jet technology looks promising, with trends pointing toward enhanced efficiency, smarter integration, and broader applications. Advances in pump design are expected to reduce energy consumption and increase pressure capabilities, making pure water jet systems more accessible and cost-effective. The integration of artificial intelligence and IoT (Internet of Things) is set to revolutionize pure water jet operations, enabling predictive maintenance, real-time adjustments, and improved precision through machine learning algorithms. In terms of materials, research is focused on expanding the range of substances that can be processed with a pure water jet, including harder composites and biomaterials, potentially opening doors in fields like renewable energy and biotechnology. Environmental considerations will drive the development of more sustainable practices, such as better water recycling systems and reduced carbon footprints. Additionally, miniaturization of pure water jet components could lead to portable devices for on-site repairs or medical uses. As industries continue to prioritize green technologies, the demand for pure water jet systems is likely to grow, fostering innovation and collaboration across sectors. By staying at the forefront of these developments, businesses can harness the full potential of pure water jet technology to achieve new levels of productivity and sustainability.

Frequently Asked Questions About Pure Water Jet

Q1: What is the main difference between a pure water jet and an abrasive water jet?

A1: A pure water jet uses only water at high pressure for cutting softer materials like foam, rubber, or food, while an abrasive water jet adds abrasive particles (e.g., garnet) to the water stream to cut harder materials such as metals or stone. The pure water jet is preferred for applications requiring no contamination or heat, whereas the abrasive version extends the capability to tougher substances.

Q2: How safe is it to operate a pure water jet system?

A2: Operating a pure water jet system is generally safe, as it produces no heat, sparks, or harmful fumes. However, safety precautions are necessary due to the high-pressure water stream, which can cause injuries if mishandled. Proper training, protective gear, and adherence to guidelines are essential to minimize risks.

Q3: Can a pure water jet be used for cleaning purposes?

A3: Yes, a pure water jet is highly effective for cleaning tasks, such as removing paint, rust, or contaminants from surfaces. Its high-pressure stream can strip layers without damaging the underlying material, making it popular in industries like shipbuilding, automotive, and infrastructure maintenance.

Q4: What types of materials are best suited for cutting with a pure water jet?

A4: A pure water jet is ideal for cutting soft materials including plastics, foams, textiles, paper, food products, and certain composites. It is not suitable for hard metals or ceramics without abrasives, but it excels in applications where precision, cleanliness, and no thermal distortion are critical.

Q5: How does the cost of a pure water jet compare to other cutting technologies?

A5: The initial cost of a pure water jet system can be higher than some traditional methods like mechanical cutting, but it often offers lower long-term expenses due to reduced material waste, minimal maintenance, and no need for consumables like blades or chemicals. However, it may be less cost-effective for high-volume hard material cutting compared to lasers or plasma systems.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read