The Science and Art of Cutting Rock With Water: How Water Jets Transform Industry

Have you ever wondered how a soft, yielding substance like water can slice through some of the hardest materials on Earth? The process of cutting rock with water is not just possible; it’s a revolutionary technology that has transformed mining, construction, and manufacturing. This method, far from being a scientific paradox, leverages fundamental physics to achieve remarkable precision and power. It’s a clean, efficient, and incredibly versatile alternative to traditional mechanical cutting and explosive blasting. This article delves into the fascinating world of hydro-demolition and waterjet cutting, exploring the principles, applications, and undeniable benefits of using water as a modern-day chisel.

The Fundamental Principles: How Pure Water Becomes a Powerful Tool

At its core, cutting rock with water is a masterclass in physics. The process is built upon two key principles: pressure and velocity. Ordinary water, when pressurized to extreme levels and forced through a tiny nozzle, transforms into a supersonic stream capable of incredible feats of erosion.

The system begins with a high-pressure pump, which intensifies the water pressure to ranges between 40,000 and 90,000 pounds per square inch (PSI). To put that into perspective, a typical pressure washer for home use operates at around 2,000 PSI. This ultra-high-pressure water is then focused through a gemstone nozzle, often made from diamond or sapphire, which can be as small as a few thousandths of an inch in diameter. This constriction accelerates the water to speeds exceeding Mach 3, over three times the speed of sound. When this needle-thin jet of water strikes a rock surface, the immense pressure over a minuscule area creates stress that exceeds the rock’s tensile strength, effectively micro-chipping and eroding the material away. The process is so precise that it can be controlled to cut intricate patterns without generating heat or causing structural damage to the surrounding material.

The Role of Abrasives: Enhancing the Power of Water

While pure waterjets are exceptionally powerful and are used for cutting softer materials, cutting rock with water typically involves an enhanced method known as abrasive waterjet cutting. For hard materials like granite, basalt, or concrete, the pure waterjet might only make a shallow dent. This is where abrasives come into play.

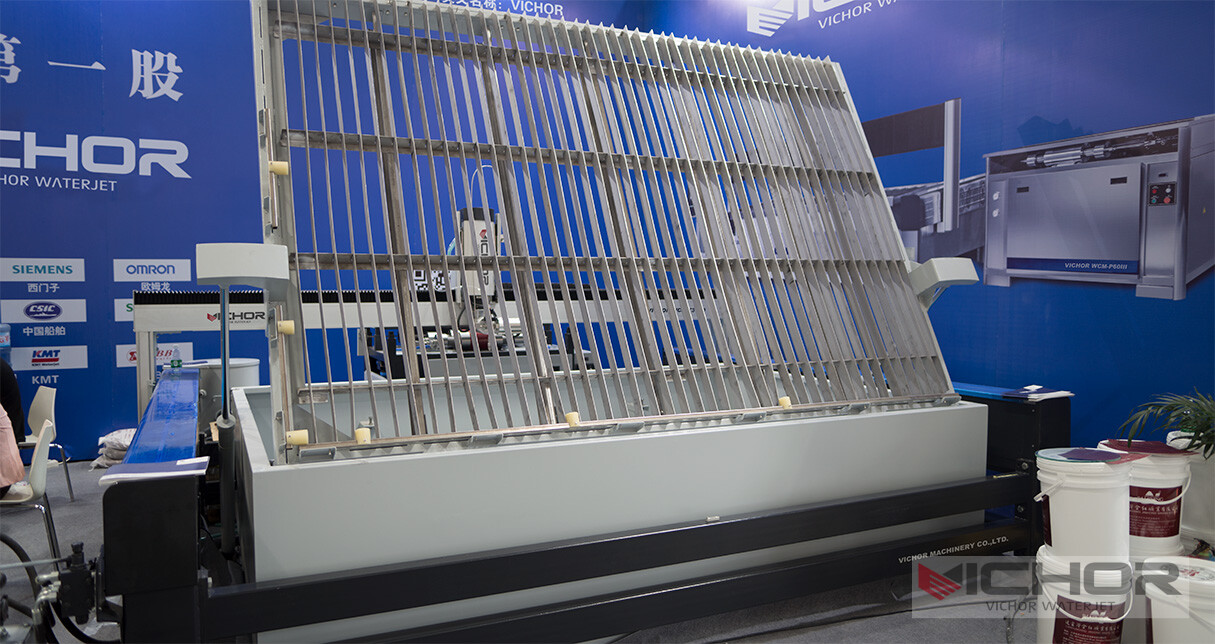

In an abrasive waterjet system, the stream of pure water is used as a carrier for extremely hard, granular particles, such as garnet or aluminum oxide. After the water exits the focusing nozzle, it enters a mixing chamber where a vacuum effect draws in the abrasive material. The water and abrasive mix inside a ceramic tube before exiting a second, wider nozzle. Now, the cutting action is no longer just water erosion; it becomes a continuous, high-velocity stream of abrasive particles micro-machining the rock surface. Each tiny particle acts like a miniature hammer, chipping away at the material. This synergistic combination allows for the effective cutting rock with water on an industrial scale, enabling the slicing through meters-thick concrete and the hardest natural stones with relative ease.

Key Industrial Applications: From Quarries to Construction Sites

The technology of cutting rock with water is not a niche laboratory experiment; it is a workhorse technology deployed across numerous global industries. Its unique advantages make it the preferred method for many challenging tasks.

In the mining and quarrying industry, abrasive waterjets are used for precision cutting and profiling of stone blocks. Unlike traditional methods that use saws with diamond-tipped blades, which create significant dust and wear down quickly, waterjets produce clean cuts with minimal material loss (kerf) and no thermal damage. This allows quarry operators to extract more usable material from a single block of marble or granite, reducing waste and increasing profitability.

In civil engineering and construction, hydro-demolition is a primary application. This involves using high-pressure waterjets to remove deteriorated concrete from bridges, roads, and parking structures while leaving the sound, reinforced concrete intact. This is far superior to jackhammering, which can create micro-fractures in the underlying substrate. Furthermore, the process is used for precise cutting in renovation projects, such a

s creating openings for doors or windows in concrete walls without causing vibrations that could compromise the building’s integrity.

The tunneling and excavation sector also benefits greatly. Waterjet technology can be integrated into tunnel boring machines (TBMs) to assist in cutting through hard rock formations, reducing the wear and tear on the mechanical cutters and increasing the overall advance rate.

Unmatched Advantages: Why Water Outperforms Traditional Methods

The shift towards cutting rock with water is driven by a compelling list of advantages that directly address the limitations of mechanical and thermal cutting techniques.

Cold Cutting Process: Perhaps the most significant benefit is that waterjet cutting is a cold process. It generates no heat-affected zone (HAZ), which is a critical flaw in laser or plasma cutting. This eliminates the risk of altering the properties of the material being cut, which is vital in construction where structural integrity is paramount.

Environmental Friendliness: The process produces no dust, a major health hazard associated with sawing and grinding rock and concrete. It also reduces noise pollution significantly compared to jackhammers and explosive blasting. The primary waste products are slurry (water and cut material), which can often be contained and treated or recycled.

Precision and Versatility: A waterjet can cut intricate shapes and patterns with exceptional accuracy, something impossible with a jackhammer or explosive. The same machine can be programmed to cut a delicate artistic sculpture from marble and then be used to slice through thick reinforced concrete, simply by adjusting the pressure and abrasive feed rate.

Minimal Mechanical Stress: Unlike pounding tools that transfer shockwaves through the material, the waterjet applies a localized, concentrated force. This prevents cracking and delamination in brittle materials, preserving the strength of the remaining structure.

The evolution of cutting rock with water is far from over. Ongoing research and development are focused on enhancing efficiency, power, and intelligence. Future trends point towards even higher-pressure systems, pushing beyond 100,000 PSI to increase cutting speeds and the thickness capacity.

Automation and robotics represent the most significant area of growth. Waterjet cutting systems are increasingly being integrated with advanced robotic arms and CNC (Computer Numerical Control) platforms. This allows for unprecedented levels of precision and allows the technology to be deployed in dangerous or inaccessible environments, such as underwater cutting, nuclear decommissioning, or deep mining operations. Smart systems equipped with sensors can now automatically adjust pressure and abrasive flow in real-time based on the material being encountered, optimizing the cut and conserving resources. As software and hardware continue to advance, the practice of cutting rock with water will become even more efficient, precise, and integral to modern industry.

In conclusion, the ability to perform cutting rock with water is a stunning example of human ingenuity turning a simple element into a powerful industrial tool. By harnessing the principles of pressure and erosion, this technology offers a cleaner, smarter, and more precise way to shape the very foundation of our world. From the quarries that provide our building materials to the infrastructure we rely on daily, waterjet cutting is quietly revolutionizing how we interact with stone and concrete, proving that sometimes the most powerful solutions flow from the simplest sources.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read