How a CNC Abrasive Waterjet Cutting Machine Works and What It Can Do For You

In the world of modern manufacturing and fabrication, precision and versatility are paramount. Among the myriad of cutting technologies available, one stands out for its unique ability to handle almost any material with cold-cutting precision: the CNC abrasive waterjet cutting machine. This powerful tool has revolutionized how industries from aerospace to art create complex parts. But what exactly is it, how does it work, and what should you know before using one? This article delves deep into the mechanics, benefits, applications, and practical considerations of this incredible technology.

What is a CNC Abrasive Waterjet Cutting Machine?

At its core, a CNC abrasive waterjet cutting machine is a computer-controlled system that uses a high-pressure stream of water mixed with abrasive particles (typically garnet) to cut through materials. The “CNC” (Computer Numerical Control) aspect is crucial—it means the machine follows a digital design file with extreme precision, guiding the cutting head along the programmed path to produce accurate and repeatable cuts every time. Unlike lasers or plasma cutters, which use heat, a waterjet is a cold-cutting process. This means it doesn’t create a Heat-Affected Zone (HAZ), alter the material’s internal structure, or generate toxic fumes, making it ideal for materials sensitive to high temperatures.

The Inner Workings: How Waterjet Cutting Achieves Precision

The process may seem simple—a jet of water cutting through metal—but the technology behind it is sophisticated. The operation can be broken down into a few key stages:

High-Pressure Pump: The heart of the system is an intensifier pump that pressurizes ordinary water to an extreme level, typically between 60,000 and 90,000 PSI (4,000 to 6,200 bar).

Water Delivery: This ultra-high-pressure water is then forced through a narrow orifice, usually made of sapphire or diamond, in the cutting head. This focuses the stream into a coherent jet moving at speeds faster than sound.

Abrasive Introduction: In the mixing tube of the cutting head, the pure water jet creates a vacuum that draws abrasive granules from a separate hopper. The water and abrasive mix intensely within the focus tube.

The Cutting Action: This resulting abrasive waterjet is expelled from the focus tube onto the workpiece. The abrasive particles do the actual cutting through mechanical erosion, essentially grinding away material at a microscopic level. The CNC system moves the cutting head on an X-Y axis, tracing the desired pattern with incredible accuracy.

Unmatched Versatility: Materials and Applications

The single greatest advantage of a CNC abrasive waterjet cutting machine is its ability to cut virtually any material. This makes it a go-to solution for job shops and specialized manufacturers alike.

Metals: From soft aluminum and copper to hardened tool steel, titanium, and brass. It handles reflective metals that challenge laser cutters and thick metals (over 6 inches) that plasma struggles with.

Stone and Tile: A mainstay for countertop fabricators creating intricate designs, sink cutouts, and tiles.

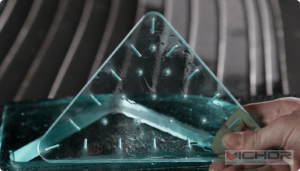

Glass: Used for artistic patterns, architectural glass, and even automotive applications without cracking the material.

Composites: Perfect for cutting carbon fiber, fiberglass, and Kevlar without fraying or delaminating the layers.

Plastics and Rubber: Cuts through various plastics without melting them, preventing the release of harmful gases.

This versatility allows one machine to serve multiple purposes, making it a highly valuable asset.

Key Advantages of Choosing Waterjet Technology

Why would a manufacturer choose a CNC abrasive waterjet cutting machine over other methods? The benefits are compelling:

No Heat-Affected Zone (HAZ): As a cold process, it preserves the material’s original integrity, hardness, and structure.

Material Flexibility: One machine for almost all materials eliminates the need for multiple dedicated cutting systems.

High Precision and Quality: CNC control allows for tight tolerances (typically within ±0.005 inches) and produces smooth edges that often require no secondary finishing.

Minimal Kerf and Nesting: The cutting kerf (width of the cut) is very narrow, allowing parts to be nested closely together, which minimizes material waste and maximizes yield.

Environmentally Friendly: The process uses water and natural abrasive (garnet), producing no hazardous fumes or vapors. The water can be recycled in closed-loop systems.

Common Questions and Challenges with Abrasive Waterjet Cutting

While powerful, the technology is not without its considerations. Here are some common questions and issues users encounter.

1. How fast is abrasive waterjet cutting?

Cutting speed is highly dependent on the material type and thickness. While it can cut very thick materials that other technologies cannot, it is generally slower than plasma cutting for thin metals and slower than laser for medium-thickness metals. However, for complex shapes in thick or diverse materials, it often proves to be the most efficient solution overall.

2. What about taper and edge quality?

A inherent characteristic of waterjet cutting is that the jet can widen slightly as it travels through the material, creating a minor taper (a wider kerf at the top than the bottom). Modern advanced CNC abrasive waterjet cutting machine software includes “taper compensation” algorithms that tilt the cutting head slightly to produce near-perfectly straight edges. Edge quality can also be managed by adjusting cutting speed—slower speeds yield smoother edges.

3. Is the operating cost high?

The two main consumables are the high-pressure pump components (seals, valves, orifices) and the abrasive garnet. While the pump requires maintenance, the abrasive is a continuous cost. However, this must be weighed against the savings from reduced material waste, the elimination of secondary finishing processes, and the ability to cut expensive materials (like titanium) with precision.

4. How loud is the machine?

Abrasive waterjet cutting is a loud process. The sound of the high-pressure stream impacting the material can exceed safe noise levels. Therefore, most systems are equipped with sound-dampening enclosures or are installed in dedicated areas where operators must wear appropriate hearing protection.

5. What maintenance is required?

Regular maintenance is essential for consistent performance and longevity. This includes:

Reaching the high-pressure pump seals and valves as recommended by the manufacturer.

Replacing the orifice (jewel) and focus tube (nozzle) regularly, as they are wear items.

Maintaining clean and dry abrasive to prevent clogs in the delivery system.

Ensuring the water filtration system is functioning to protect the pump from sediment.

The CNC abrasive waterjet cutting machine is a remarkably flexible and powerful fabrication tool. Its unique cold-cutting process, unparalleled material versatility, and high precision make it an indispensable asset for any operation that works with a diverse range of materials or requires perfect cuts without thermal distortion. While considerations like speed, operating costs, and maintenance are important, the benefits often overwhelmingly justify the investment. By understanding its capabilities and challenges, you can effectively leverage this technology to push the boundaries of what’s possible in manufacturing and design.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read