Unlocking the Potential of 2 Axis Waterjet Cutting: A Deep Dive into Precision and Performance

In the world of industrial manufacturing and fabrication, precision cutting is paramount. Among the myriad of technologies available, 2 axis waterjet cutting stands out as a versatile and powerful solution. This process harnesses the immense power of water, often mixed with an abrasive substance, to slice through a vast array of materials with incredible accuracy. Unlike its more complex multi-axis counterparts, 2-axis cutting operates on a straightforward X and Y coordinate plane, making it a workhorse for a huge range of applications. This article will explore the intricacies of 2 axis waterjet cutting, from its fundamental principles to its common challenges, providing a comprehensive understanding of this remarkable technology.

What is 2 Axis Waterjet Cutting and How Does It Work?

At its core, 2 axis waterjet cutting is a subtractive manufacturing process that uses a high-pressure stream of water to cut material. The “2 axis” designation means the cutting head moves in two linear directions: the X-axis (left and right) and the Y-axis (forward and backward). This movement is typically controlled by a computer numerical control (CNC) system, which follows a digital design file to produce precise shapes and patterns.

The process begins with a regular water supply, which is then pressurized by an ultra-high-pressure pump to levels exceeding 60,000 PSI (often reaching 90,000 PSI). This pressurized water is then forced through a small orifice, usually made of sapphire or diamond, creating a supersonic jet. For cutting harder materials like metals, stone, or ceramics, an abrasive material (such as garnet) is introduced into the stream within a mixing tube. This abrasive jet acts like a saw, eroding the material along the predetermined path. The simplicity of the 2-axis movement makes the system incredibly robust and well-suited for producing flat parts with complex geometries and tight tolerances.

The Unmatched Advantages of 2 Axis Waterjet Cutting

Why has 2 axis waterjet cutting remained a popular choice for decades? The benefits are numerous and significant for many businesses.

Cold Cutting Process: Unlike laser or plasma cutting, waterjet cutting does not generate heat-affected zones (HAZ). This means the material’s inherent structure remains unchanged, preventing warping, hardening, or altering the material’s properties. This is crucial for materials like tool steel or tempered glass.

Material Versatility: This is arguably its greatest strength. A single 2 axis waterjet cutting machine can cut through metal, stone, glass, composites, rubber, foam, and food products. There is virtually no other single cutting technology that can handle such a diverse range of materials without requiring extensive re-tooling.

High Precision and Accuracy: CNC-controlled 2 axis waterjet cutting systems can achieve remarkable precision, often holding tolerances within ±0.005 inches (±0.13 mm). They produce clean edges with a minimal kerf (the width of the cut), reducing material waste.

No Tooling Changes: Since the “cutting tool” is a stream of water and abrasive, there is no need for physical tooling like drills or blades. Switching from cutting aluminum to cutting titanium only requires changing the CNC program, not the machine’s hardware, leading to faster job turnaround.

Environmental Friendliness: The process produces no hazardous fumes or gases. The primary waste products are water and used abrasive, both of which can be managed and recycled in modern systems.

Common Applications Across Industries

The versatility of 2 axis waterjet cutting ensures its place in a wide array of sectors. Its ability to handle diverse materials makes it indispensable for:

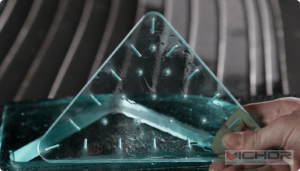

Architecture and Design: Creating intricate patterns in marble, granite, and glass for countertops, flooring, and artistic installations.

Aerospace and Aviation: Cutting lightweight composites, titanium alloys, and aluminum components where precision and lack of heat stress are non-negotiable.

Automotive Manufacturing: Producing gaskets, interior trim, body panels, and insulation components from various materials.

Industrial Machinery: Fabricating parts from high-strength steels, bronze, and copper without compromising their temper.

Food Industry: Precisely cutting frozen goods, cakes, and other food products hygienically without cross-contamination (using pure water jets).

Navigating Common Challenges and Problems in 2 Axis Waterjet Cutting

Despite its many advantages, operators of 2 axis waterjet cutting systems can encounter several common issues. Understanding these problems is key to maintaining efficiency and quality.

Taper and Kerf Angle

One of the most frequent issues in 2 axis waterjet cutting is taper. This is the phenomenon where the cut is not perfectly vertical, resulting in a slightly wider kerf at the top of the material than at the bottom. It occurs because the waterjet stream loses energy and diverges as it travels through the material. For many applications, a slight taper is acceptable, but for parts requiring perfect vertical walls, it is a problem.

Solution: Using advanced cutting heads with dynamic taper compensation can adjust the cutting head’s angle during the process to produce near-vertical walls. Slowing the cutting speed can also reduce taper but at the cost of productivity.

Nozzle and Component Wear

The abrasive garnet used in the cutting process is essential but also causes wear on the machine’s components. The orifice, mixing tube, and waterjet seals are all subject to degradation over time. A worn nozzle can lead to a wider, less focused jet, reducing cut quality and precision.

Solution: Implementing a strict preventive maintenance schedule is crucial. Regularly inspecting and replacing worn parts like the orifice (every 50-100 cutting hours) and mixing tube (every 10-20 cutting hours) ensures consistent cut quality. Using high-quality abrasives that are properly sized can also extend component life.

Slow Cutting Speeds on Thick Materials

While waterjets can cut very thick materials, the process becomes significantly slower as thickness increases. Cutting through 4-inch-thick steel is possible but can take a considerable amount of time compared to thinner sheets.

Solution: Optimizing cutting parameters—such as pressure, abrasive flow rate, and traverse speed—for specific material types and thicknesses is essential. Sometimes, a multi-axis system that can tilt the head might be more suitable for very thick materials, but for a 2 axis machine, patience and parameter optimization are the answers.

Water Management and Slurry Disposal

The process generates a slurry of water, abrasive particles, and microscopic material waste. Managing this waste stream can be messy and requires a proper disposal system. Stagnant water can also lead to bacterial growth in the tank if not properly maintained.

Solution: Modern systems are equipped with closed-loop water recycling systems and settling tanks that separate the abrasive and material sludge from the water, allowing for cleaner disposal and water reuse. Regular tank cleaning is a necessary part of operational upkeep.

Edge Quality and Surface Finish

The edge left by a waterjet is typically smooth but has a matte, satin finish. At higher cutting speeds, a visible “strike” or ripple pattern may appear on the cut edge. For some applications, this may require secondary finishing operations.

Solution: For a smoother edge, operators can use slower cutting speeds or employ specialized software that incorporates “quality modes” for cutting contours at a reduced speed. Piercing the material correctly also prevents blowback that can roughen the top surface.

2 axis waterjet cutting remains a cornerstone technology in modern manufacturing. Its unique combination of versatility, precision, and cold-cutting operation makes it an invaluable tool for shops looking to handle a diverse set of materials and jobs without investing in multiple dedicated machines. While challenges like taper, nozzle wear, and speed on thick materials exist, they are well-understood and manageable with proper maintenance and operational practices. For anyone involved in fabrication, understanding the capabilities and requirements of 2 axis waterjet cutting is key to unlocking its full potential for producing high-quality, complex parts efficiently and effectively.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read